Cleaning control method of cleaning machine

A control method and technology for cleaning machines, applied in electrical program control, program control in sequence/logic controllers, color/spectral characteristic measurement, etc., can solve the problems of long time, short time, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

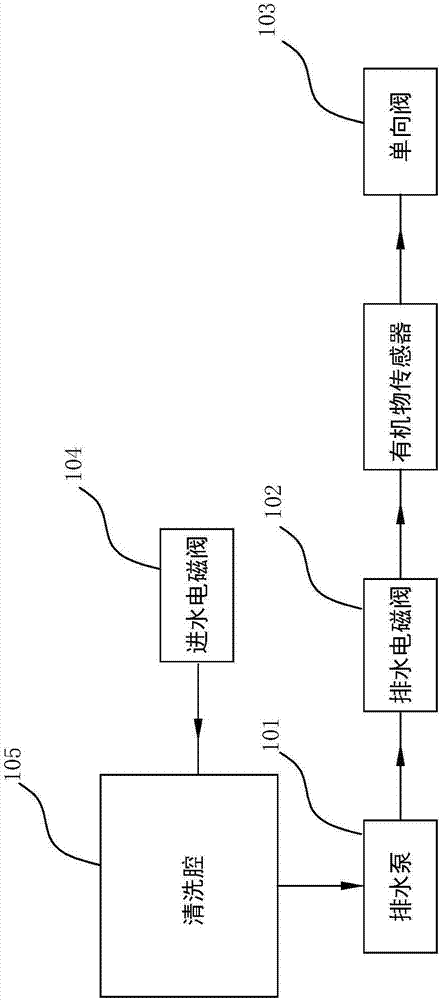

[0030] Such as figure 1 The shown cleaning machine includes a cleaning chamber 105, a water inlet system for flushing cleaning water into the cleaning chamber 105, and a drainage system for discharging the cleaning water in the cleaning chamber 105, wherein the water inlet system includes a water inlet solenoid valve 104, the drainage system includes a drainage pump 101, a drainage solenoid valve 102, an organic matter sensor for detecting organic matter content in the drainage, and a one-way valve 103, wherein the water inlet of the drainage pump 101 is connected to the drainage port of the cleaning chamber 105 of the washing machine, and the drainage pump The drain of 101 is connected with the first end of the drain solenoid valve 102, the second end of the drain solenoid valve 102 is connected with the water inlet of the organic matter sensor, and the water outlet of the organic matter sensor is connected with the drain pipe of the cleaning machine after the check valve 103 ...

Embodiment 2

[0053] The difference from Embodiment 1 is that the drainage system of the washing machine includes a drainage pump 101, a first drainage solenoid valve 102a, a second drainage solenoid valve 102b and a one-way valve 103, see Figure 6 As shown, the water inlet of the drain pump 101 is connected to the drain port of the washing machine cleaning chamber, the drain port of the drain pump 101 is connected to the first end of the first drain solenoid valve 102a, and the second end of the first drain solenoid valve 102a is connected to the organic matter The water inlet of the sensor is connected, the water outlet of the organic matter sensor is connected with the first end of the one-way valve 103, and the second end of the one-way valve 103 is connected with the drain pipe of the cleaning machine; The drain port of the pump is connected, and the second end of the second drain solenoid valve 102b is also connected with the first end of the one-way valve 103; when the prewashing pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap