a gas processor

A processor, gas technology, used in ionic air purification machines. It can solve the problems of non-reversible main fan, increased power consumption, inconvenient cleaning, etc., and achieve the effect of easy extraction for cleaning and maintenance, saving cooling fan, and good washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

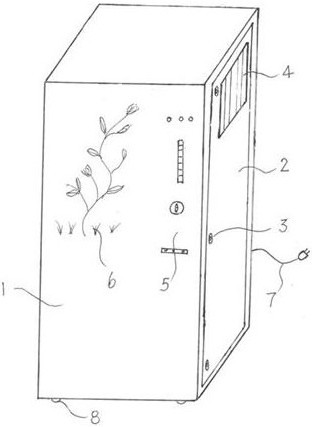

[0012] exist figure 1 Among them, a door 2 is arranged on one side of the housing 1, a sealing strip is installed on the frame of the door, the door is hingedly connected with the housing, a lock 3 is arranged on the other side of the door, and an air inlet 4 is arranged on the upper part of the door; An air outlet is provided on the upper part of one side, and a one-way door is provided on the housing below the air outlet, so that the air flow flows out from the inside to the outside in one direction; the front of the housing is provided with a control panel 5 and a decorative surface 6; The electrical part provides power; the bottom of the housing is provided with casters 8 for easy movement.

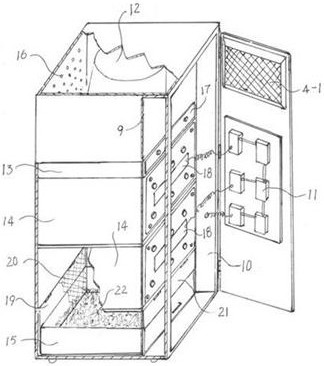

[0013] exist figure 2 Among them, the inside of the door air inlet 4 is provided with a filter device 4-1, and a partition 9 is provided on the side of the housing to divide the housing cavity into two parts. There is an air flow channel 10 between the partition and the door. Elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com