A speed measurement method for hot-rolled coils combined with a line array camera

A technology of line scan camera and area scan camera, which can be applied to devices using optical methods, etc., can solve problems such as image quality reduction and impact on speed measurement accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

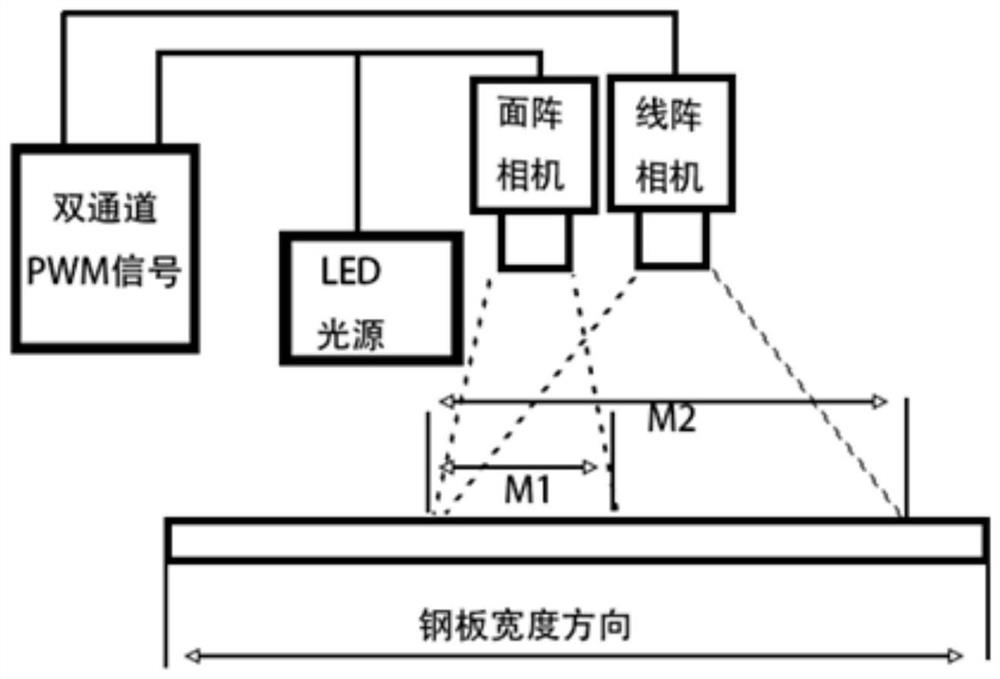

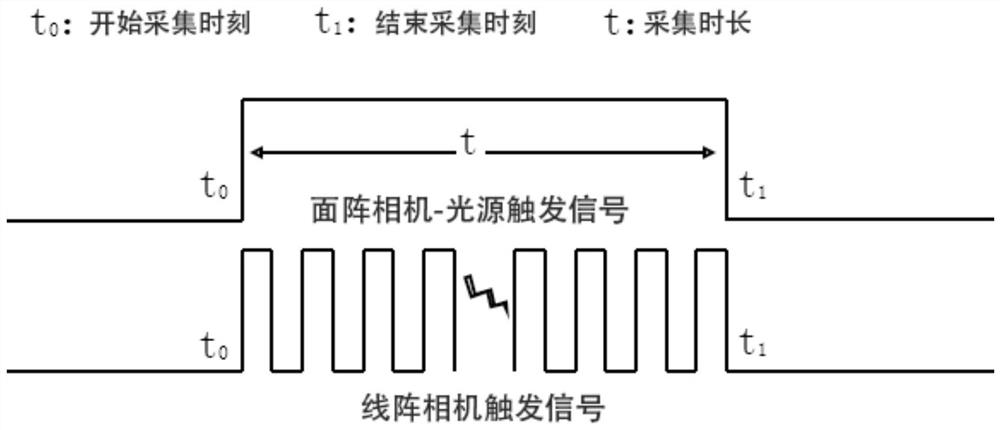

[0039] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0040] The present invention aims at the problem that the existing area array camera has a high acquisition frame rate, and the excessively high acquisition frame rate will reduce the image quality and affect the speed measurement accuracy, and provides a method for measuring the speed of hot rolled coils combined with a line area array camera.

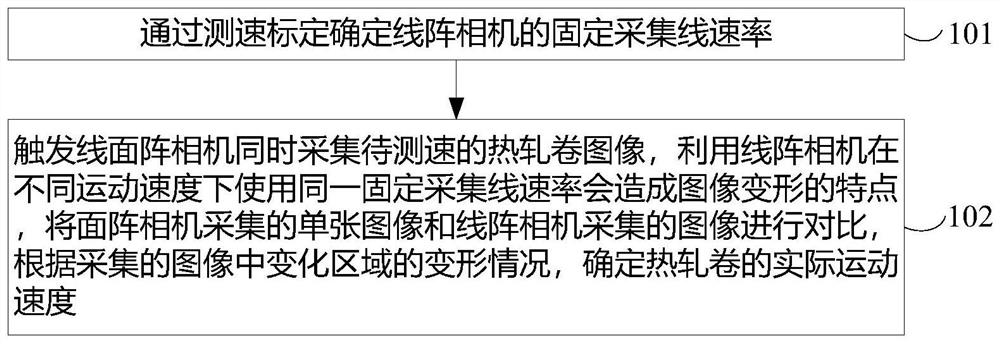

[0041]like figure 1 As shown, the method for measuring the speed of a hot-rolled coil combined with a line array camera provided in an embodiment of the present invention includes:

[0042] S101, determining a fixed acquisition line rate of the line array camera through speed measurement calibration;

[0043] S102, triggering the line array camera to simultaneously collect images of the hot-rolled coils to be m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com