Push switch

a push switch and push plate technology, applied in the direction of contact surface shape/structure, snap-action arrangement, contact, etc., can solve the problem of complicated to achieve the intended pressing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]A preferred embodiment of the present invention is described with reference to drawings.

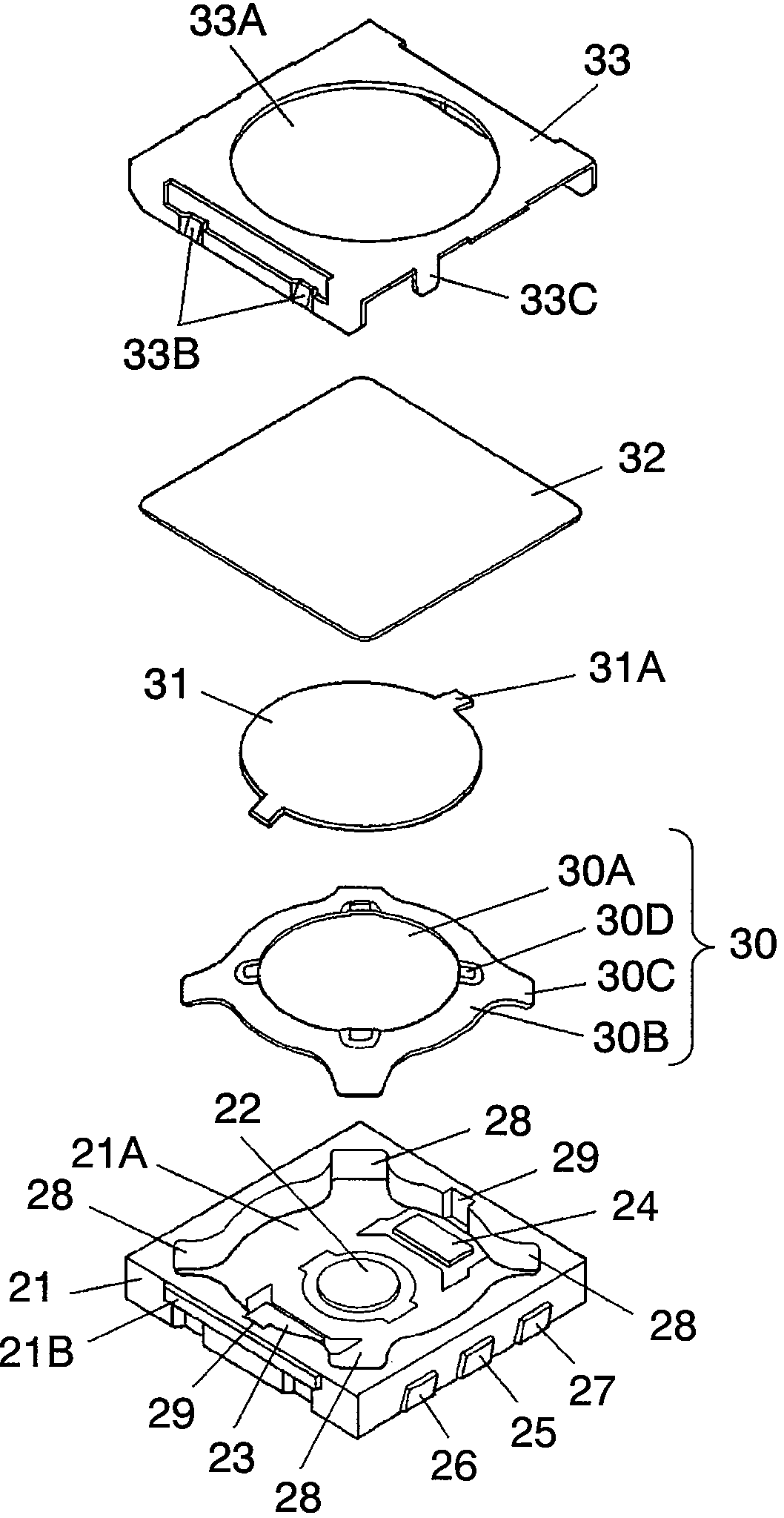

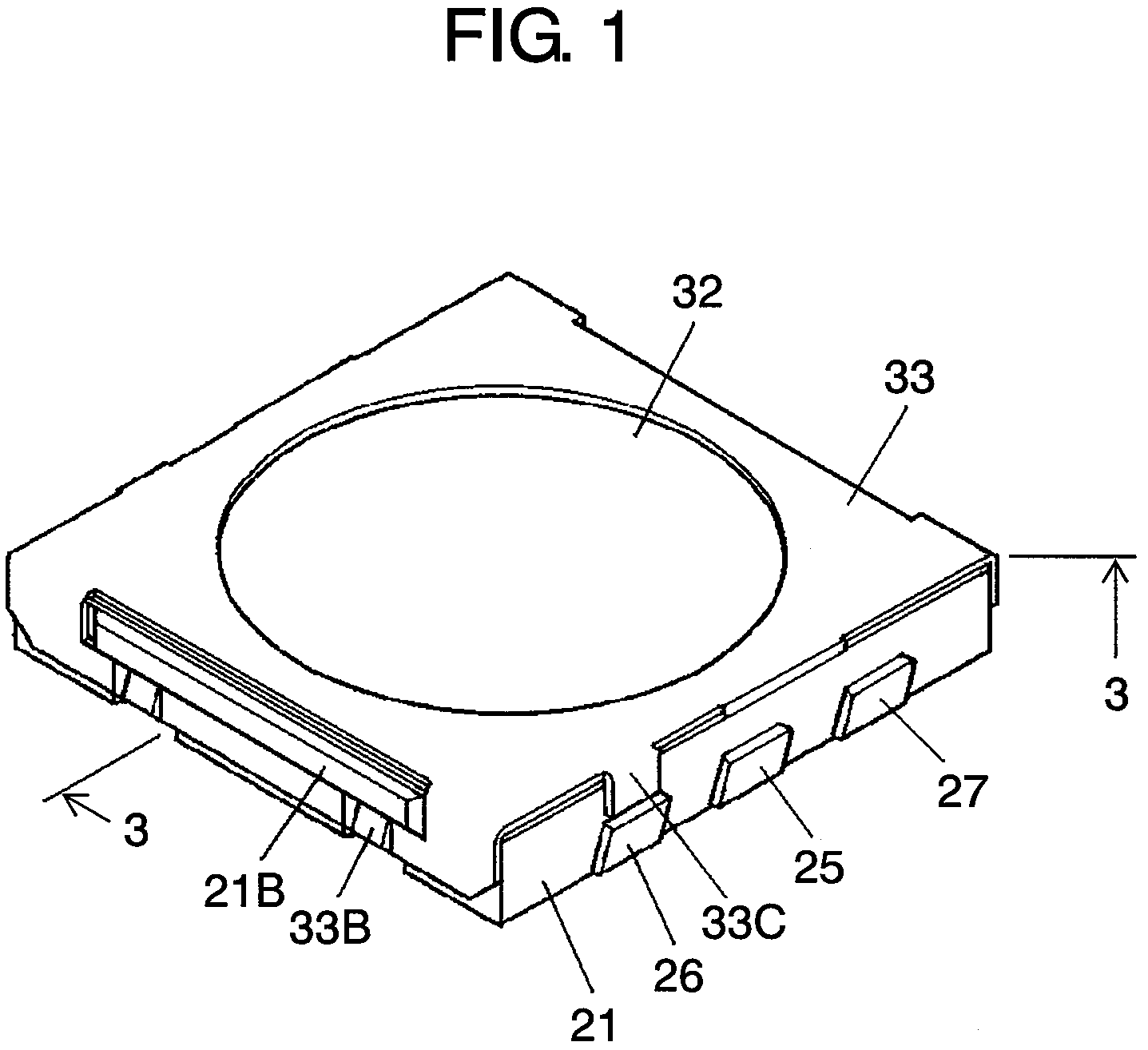

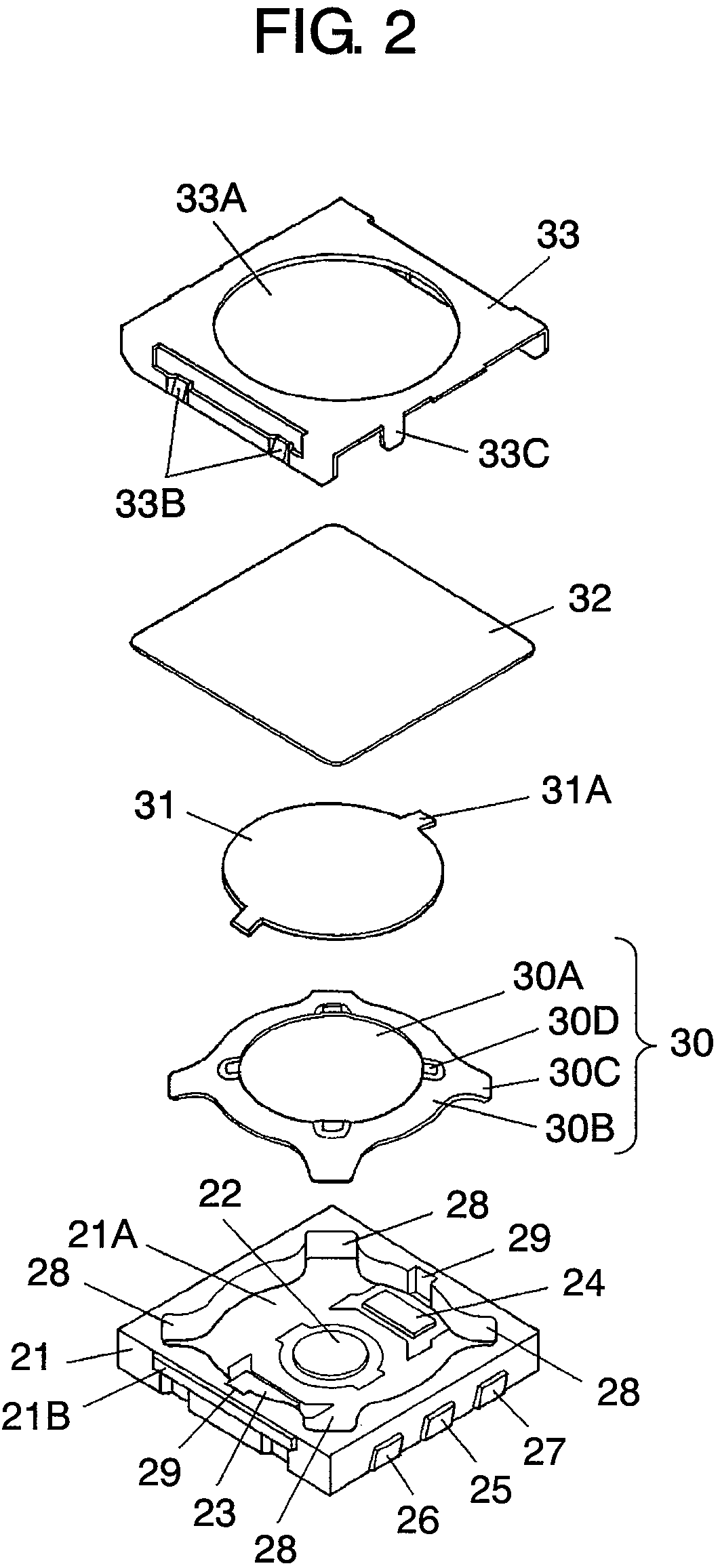

[0043]FIG. 1 is an outline view of a push switch in the preferred embodiment of the present invention. FIG. 2 is an exploded perspective view, and FIG. 3 is a sectional view taken along line 3-3 in FIG. 1. FIG. 4 is a sectional view taken along line 3-3 in FIG. 1, illustrating a first-step operation. FIG. 5 is a sectional view taken along line 3-3 in FIG. 1, illustrating a second-step operation. FIG. 6 is a chart of tactile curves.

[0044]In FIGS. 1 to 3, square switch case 21 made of insulating resin has substantially round recess 21A that has an open top. On an inner bottom face of this recess 21A, central fixed contact 22 is disposed at the center and independent peripheral fixed contacts 23 and 24 are disposed at two points symmetrical about central fixed contact 22. Second connecting terminal 25 electrically connected to central fixed contact 22 and first connecting terminals 26 and 27 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com