Actuator for an optical scanner

A technology of optical scanners and actuators, which is applied in the configuration/installation of the head, can solve the problem of the limitation of the number of tracks, and achieve the effect of reducing the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

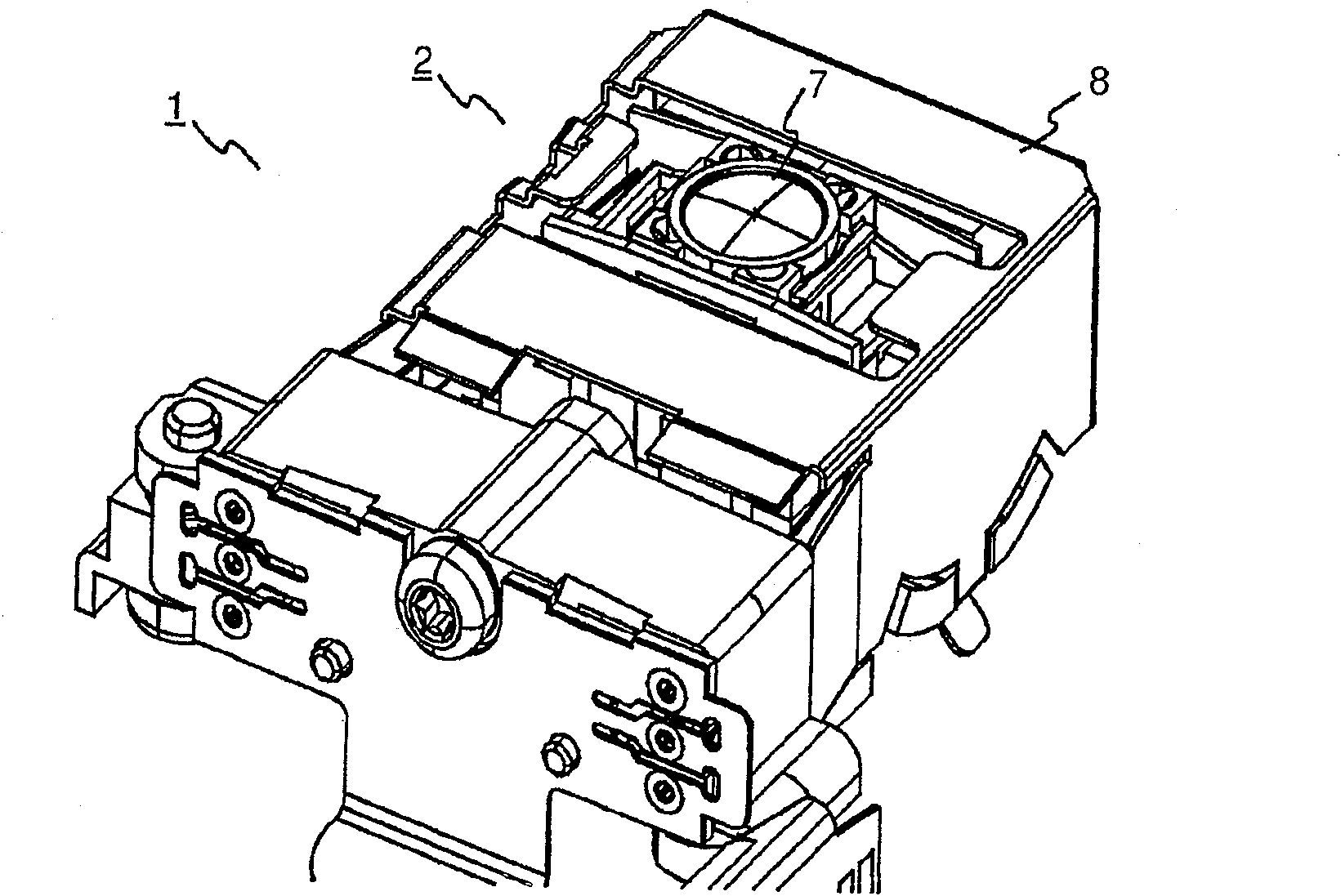

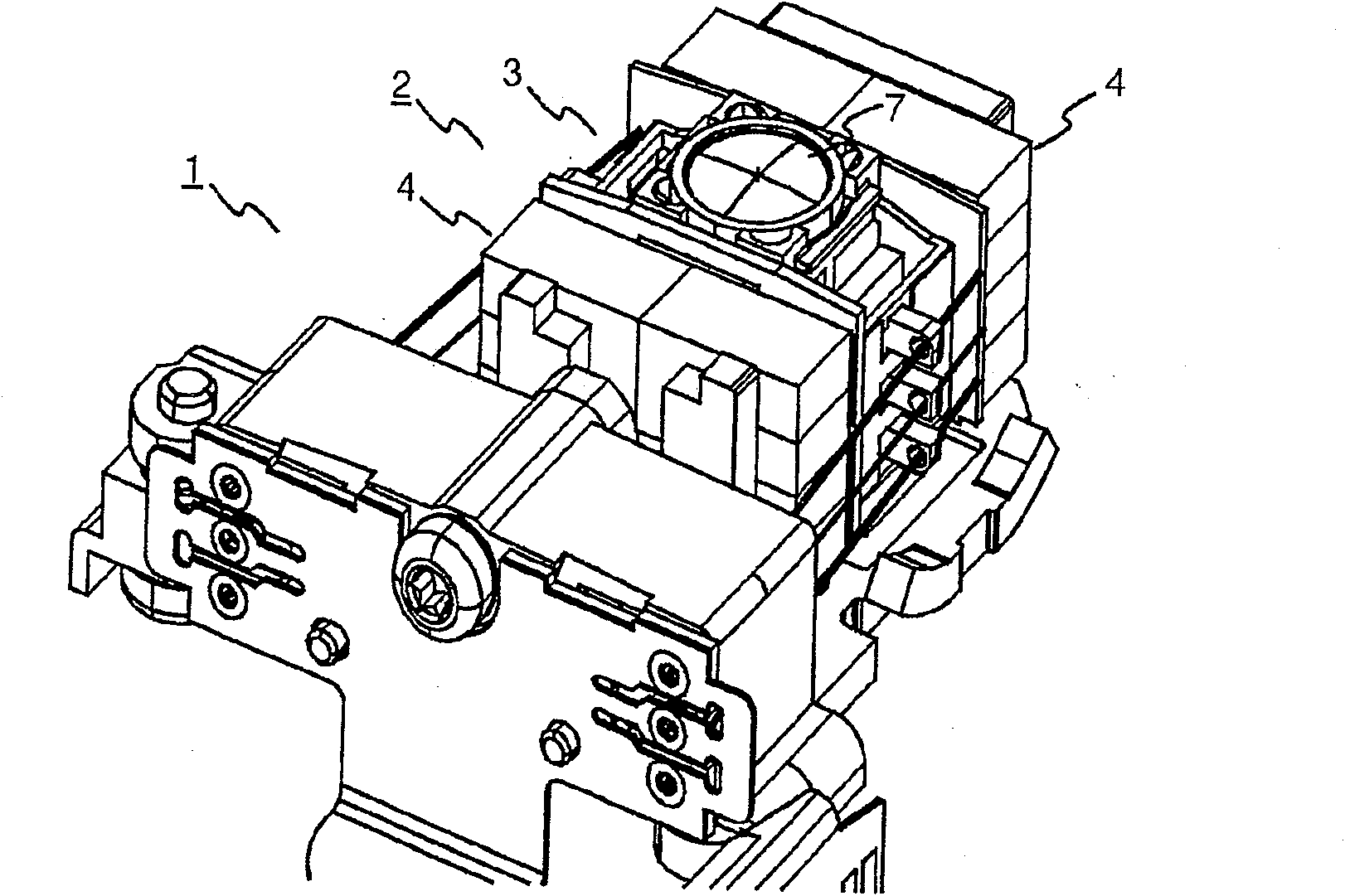

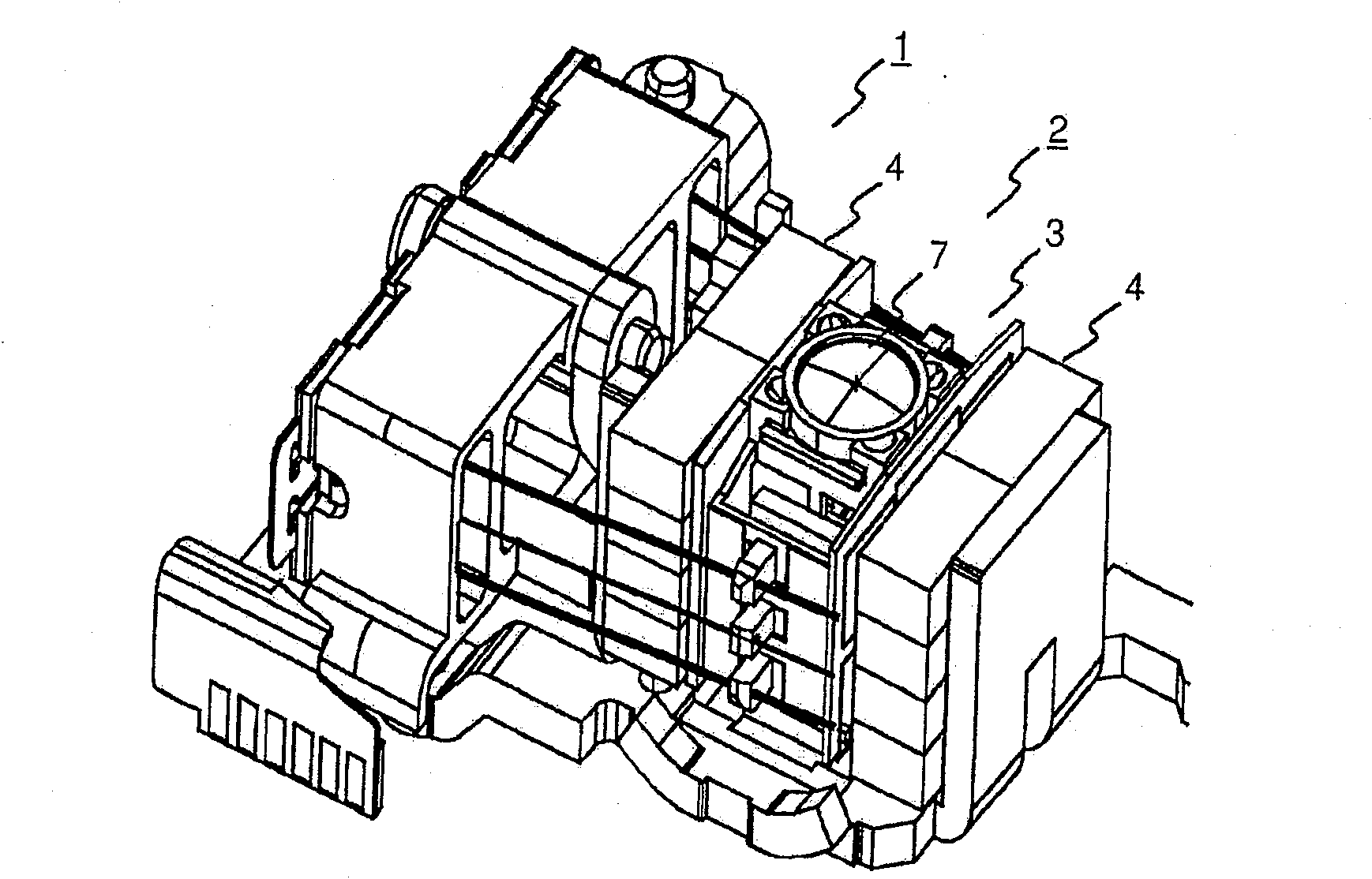

[0021] figure 1 A scanner 1 for an optical storage medium is shown, which uses an actuator 2 according to the invention for focus and tracking control by moving an objective lens vertically and horizontally. In the figure, the actuator 2 is partially concealed by a cover 8 . exist figure 2 The situation after removing the cover 8 of the optical scanner 1 is shown in . As can now be seen, the actuator 2 has a lens holder 3 for supporting the objective lens 7, and two magnets 4 for focusing and tracking control, which are arranged on one side of the lens holder 3 and associated printed coils 5, 6 interaction (in figure 2 cannot be seen in ). image 3 Views of the optical scanner 1 from different viewing angles are shown. The other elements of the optical scanner 1 are known to those skilled in the art and will not be explained in more detail here.

[0022] Figure 4 The lens holder 3 with the printed coil set 5, 6, ie the actuator 2 without the magnet 4 is shown. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com