Industrial chain grate boiler isobaric isobaric air feeding device

A chain grate and air supply device technology, which is applied in the field of uniform pressure air supply devices, and can solve problems such as lack of equal pressure air supply, uneven air distribution, and uneven air supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

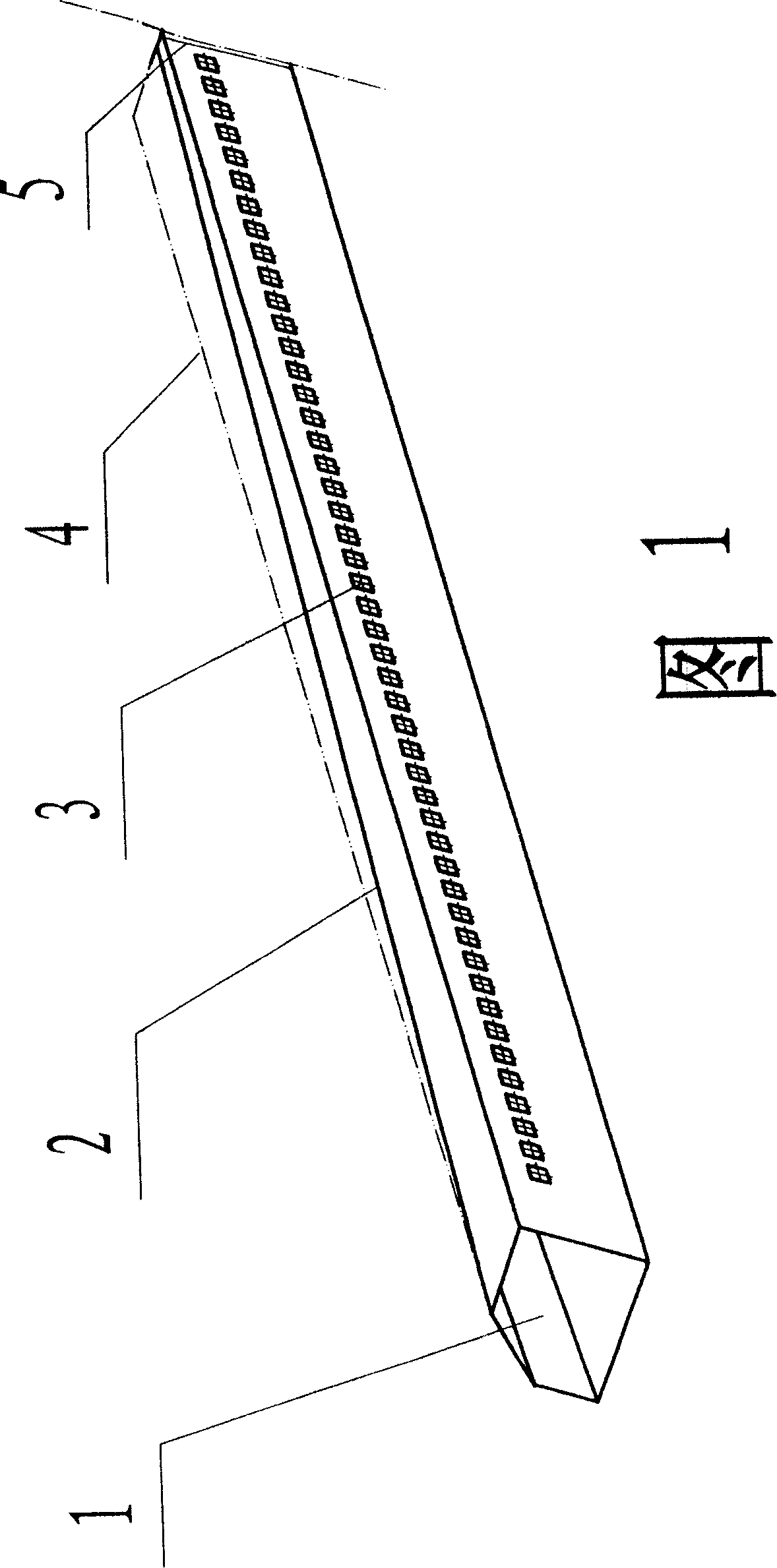

[0012] With reference to the accompanying drawings, the composition structure of an isobaric air supply device for an industrial chain grate boiler: 1. The air ducts for air intake on both sides, under the action of 2. the air distribution plate, and 5. the middle isolation plate. Combustion air enters 4, isobaric air chamber from 3, side air outlet.

[0013] Isobaric air supply device for industrial chain grate boiler, including air duct, air distribution plate, side air outlet, intermediate isolation plate, and equal pressure air chamber. An air distribution plate is arranged in the air duct, and a side air outlet is provided on the side of the air duct, and the side air outlet is connected to an equal-pressure air chamber, and an intermediate isolation plate is arranged in the middle of the equal-pressure air duct.

[0014] The cross section of the air duct can be in various shapes such as circle, rectangle or deformed rectangle; the area of the cross section decreases gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com