Manufacturing method of double-faced waterproofing pile-face dual-purpose leather of indumentum and leather boards

A production method and quilt technology, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, application, etc., can solve damage, waterproofing agent and waterproofing agent cannot be used fixed other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0178] Example 1 Leather board waterproof treatment and dyeing, retanning, fatliquoring process treatment

[0179] The dual-purpose suede leather base is first processed as follows:

[0180] 1. Dyeing quilt

[0181] Water temperature: 60~65℃

[0182] Leveling agent DP (Fanbo Company): 0.5g / L

[0183] Salt: 10g / L

[0184] Dye (dyed reddish brown): Xili fur red brown R-OD 0.3g / L Xili fur golden GMK0.1g / L (Beijing Fanbo Technology Co., Ltd.))

[0185] Formic acid: 1g / L

[0186] Operation: Adjust the water temperature and water volume, add leveling agent and salt, and then cast the skin. After 15 minutes, add the dye. After the dye is melted with hot water, add it. After 1 hour, add 0.5g / L formic acid to fix the color, and then swipe. Add 0.5g / L formic acid for 30 minutes, and then paddle for 30 minutes to wash with water. The amount of salt or formic acid used does not limit the present invention.

[0187] 2. Retanning

[0188] Water temperature: 35°C

[0189] Penetrant ...

Embodiment 2

[0224] Embodiment 2 hair is waterproofed

[0225] The fur obtained among the middle of embodiment 1 is carried out following process processing:

[0226] 1. Apply wool repellent

[0227] Equipment: grooving

[0228] Temperature: room temperature

[0229] Liquid ratio: 10

[0230] Water repellent: fluorine-based polyacrylic acid water and oil repellent finishing agent Advanproof WRC-LT (Hong Kong Pioneer Co., Ltd.) 5~10g / L

[0231] Operation: Add water to the scratching groove, add waterproofing agent, scratch evenly, soak the fur in the waterproofing agent solution, row for two hours, and the skin will come out.

[0232] 2. Squeeze

[0233] Operation: Use a vertical rolling mill to squeeze the liquid, and the residual rate of the liquid rolling is about 70% (v / v). The excess liquid squeeze rate is the liquid in the fur.

[0234] 3. Dry the skin board

[0235] Operation: Hang the leather board facing out to dry naturally.

[0236] 4. Fixed wool waterproofing agent

[...

Embodiment 3

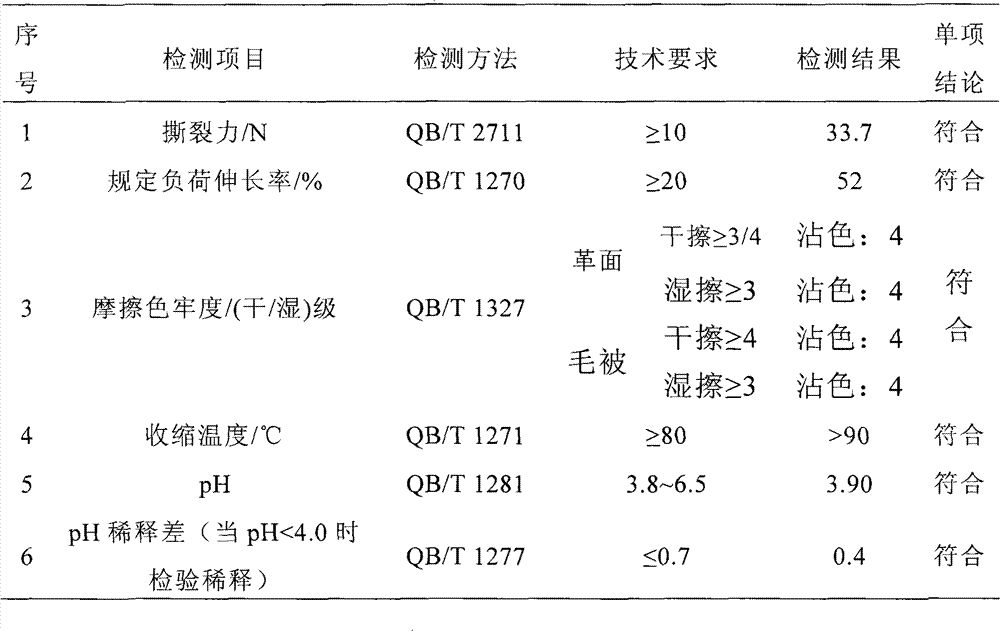

[0239] Example 3 Detection of double-sided waterproof suede dual-purpose leather of wool quilt and leather board

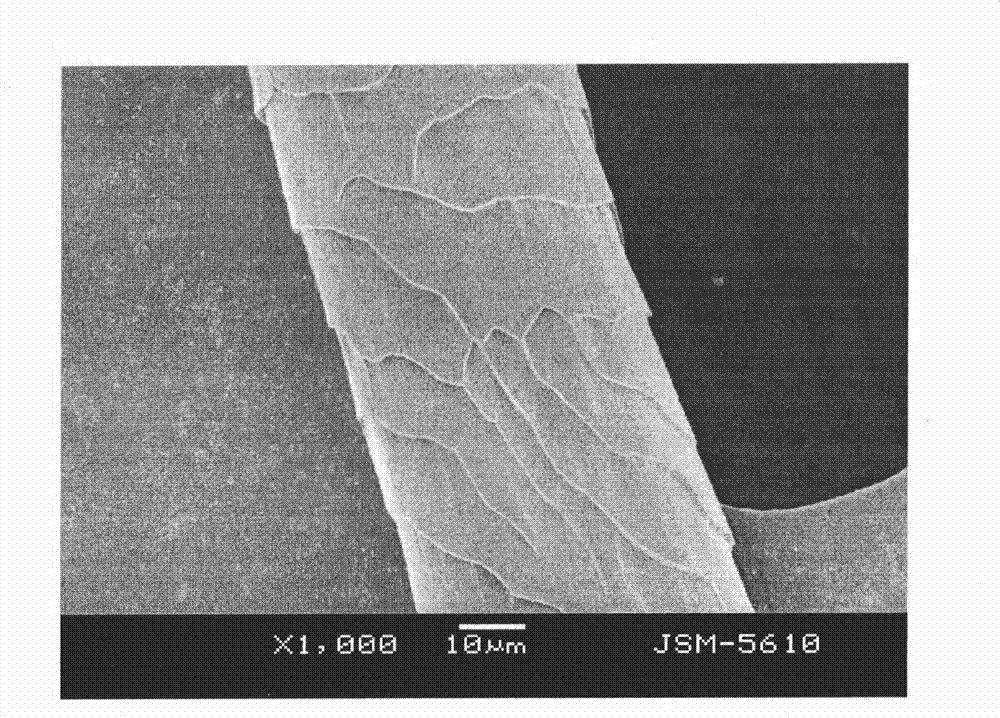

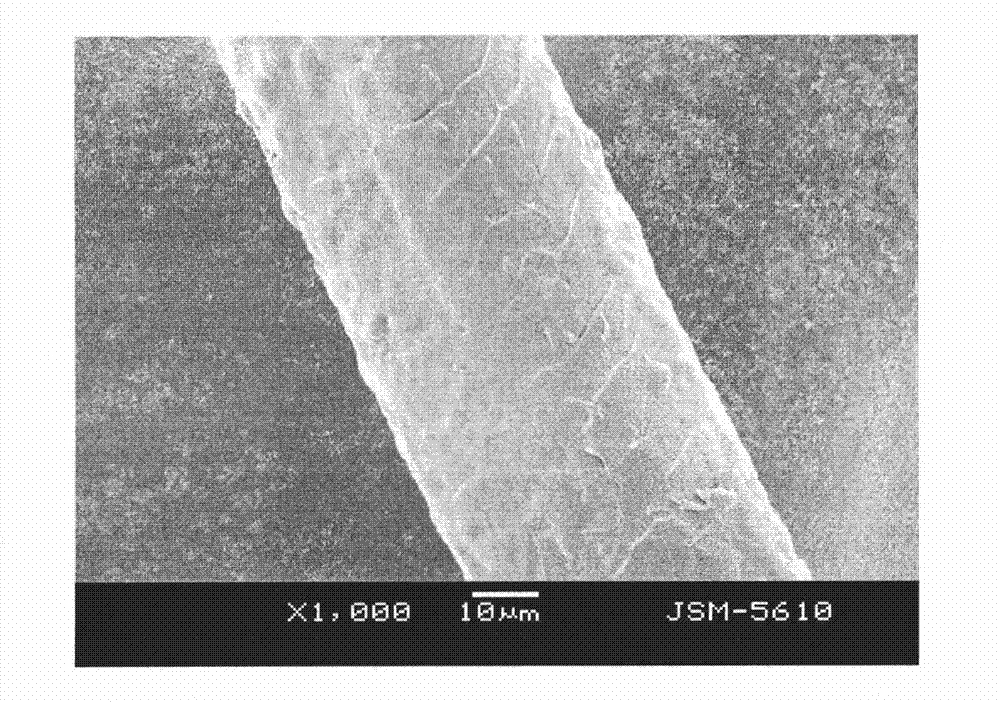

[0240] After the dual-purpose suede leather base is processed by the process of embodiment 1 and embodiment 2, the micrograph of the appearance change of wool fiber before and after waterproof treatment is as follows figure 1 , figure 2 shown.

[0241] Depend on figure 1 and figure 2 It can be seen that after the suede dual-purpose leather has been processed by the three major processes of suede dual-purpose leather blank production, leather panel waterproofing and dyeing, retanning, fatliquoring and wool quilt waterproofing, the surface scales of the wool fiber Many gully-shaped fine lines have been significantly improved, and the surface of the wool fiber is covered with a layer of water-repellent film, which enhances the water-repellent effect of the wool fiber and increases the flow speed of water droplets on its surface.

[0242] The wool quilt and doub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com