Knitting method of heel parts of socks

A heel and sock technology, applied in weft knitting, socks, knitting, etc., can solve the problem that the heel cannot be formed larger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

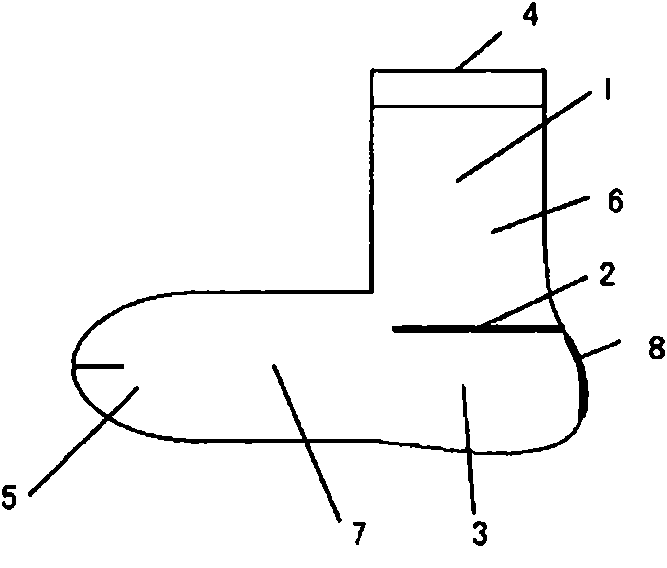

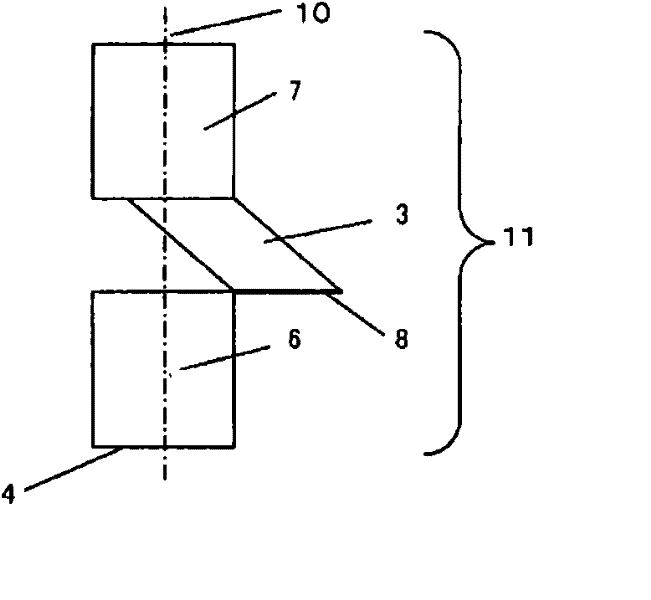

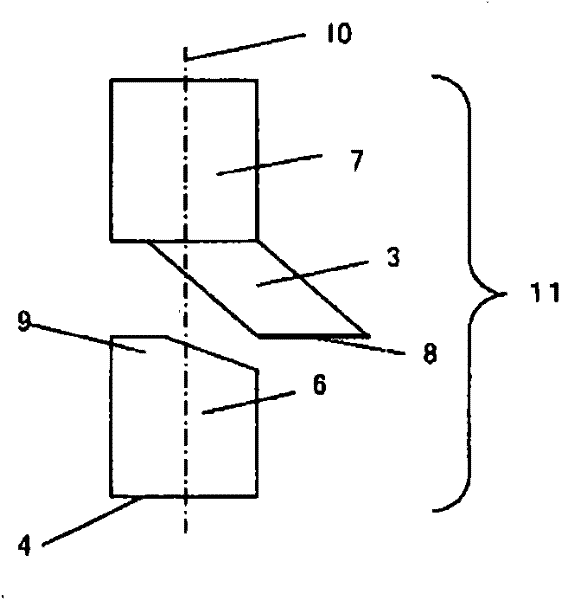

[0039] Hereinafter, suitable embodiments of the present invention will be described with reference to the drawings. In addition, in the figures used in the description, the first cylindrical portion 6 and the second cylindrical portion 7 have the same knitting width. For example, the knitting width of the first cylindrical portion 6 and the second cylindrical portion 7 are 80 respectively. needle. In addition, the dashed-dotted line in the knitting diagram indicates the center line 10 with the collection of parts as the knitted fabric 11. figure 1 The sock 1 shared by left and right knitted by the knitting method of the first embodiment or the second embodiment of the present invention is shown. The sock 1 is composed of a first cylindrical portion 6, a heel portion 3, and a second cylindrical portion 7. In addition, the sock 1 joins the first cylindrical portion 6 and the heel portion 3 at a vertical or substantially vertical angle, and a horizontally extending seam line 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com