Decorative paper water-based gravure printing ink composition

A technique of gravure printing and composition, which is applied in the application field of decorative paper gravure printing coloring technology, can solve problems such as color drift, lower product competitiveness, and insufficient dry fastness of printed products, and achieve good color reproduction reproducibility, dipping The speed is good, and the effect of impregnation does not fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

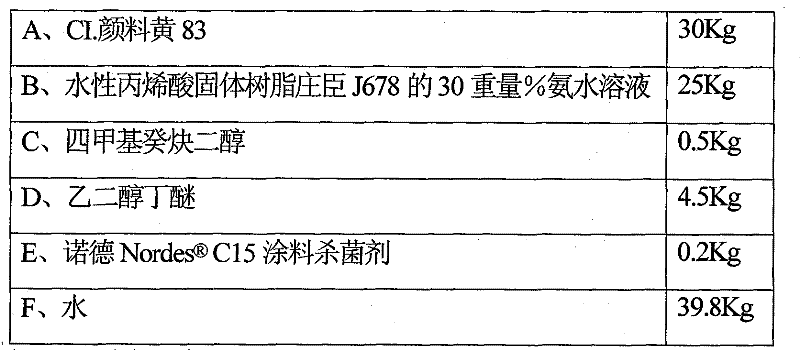

[0035] The raw materials with the following weights were weighed, mixed and beaten, and ground to a particle size of 0.5um by a bead mill under cooling conditions, then the pigment concentration was adjusted with demineralized water, and the grinding medium and water-based color paste were separated to obtain ink.

[0036]

[0037] The ink composition has bright color, high color yield, stable storage and no foam. The implementation of printing has excellent printability, good fastness, and good penetration of dipping glue.

Embodiment 2

[0039] The raw materials with the following weights were weighed, mixed and beaten, and ground to a particle size of 0.5um by a bead mill under cooling conditions, then the pigment concentration was adjusted with demineralized water, and the grinding medium and water-based color paste were separated to obtain ink.

[0040] A. CI. Pigment blue 15:3

[0041] 20% by weight of ammonia solution of B, Korea Hanwha water-based acrylic solid resin S20

[0042] The ink composition has good dipping and penetration after printing. The printing drying speed is fast, and the impregnation penetration speed is fast.

Embodiment 3

[0044] The raw materials with the following weights were weighed, mixed and beaten, and ground to a particle size of 0.5um by a bead mill under cooling conditions, then the pigment concentration was adjusted with demineralized water, and the grinding medium and water-based color paste were separated to obtain ink.

[0045] A. Carbon black

20Kg

40% by weight of ammonia solution of B, aqueous acrylic solid resin Johnson J678

35Kg

C. Tetramethyldecynediol

0.7Kg

D. Ethylene glycol butyl ether

4.5Kg

F. water

39.8Kg

[0046] The ink composition has the color yield of Example 1, no foam, excellent printability, good fastness, and good dipping and penetration.

[0047] The colors of the above-mentioned ink composition of the present invention can be mixed in any proportion to adjust the desired color, and the pigment color paste can be diluted to any concentration with a lightening agent, which is convenient for applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com