Station reversing mechanism for moulding mould of sound-proof felt automatic moulding machine

An automatic forming machine and forming mold technology, which is applied in felting equipment, textiles, papermaking, non-woven fabrics, etc., can solve the problems that the automatic forming machine for automobile sound insulation felt cannot be miniaturized and integrated, and meets the requirements of building blocks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable the examiners of the patent office, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail below in conjunction with the accompanying drawings in the form of embodiments, but none of the descriptions of the embodiments is a description of the present invention. Restriction of the inventive solution, any equivalent transformation made according to the concept of the present invention which is only in form but not in substance shall be regarded as the scope of the technical solution of the present invention.

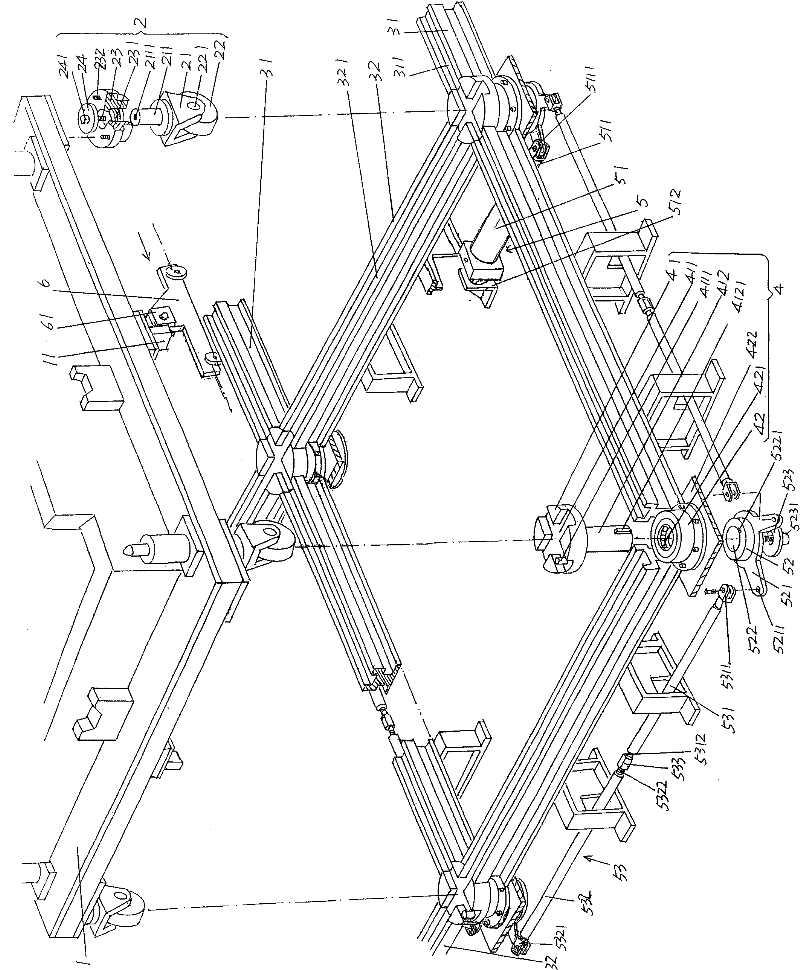

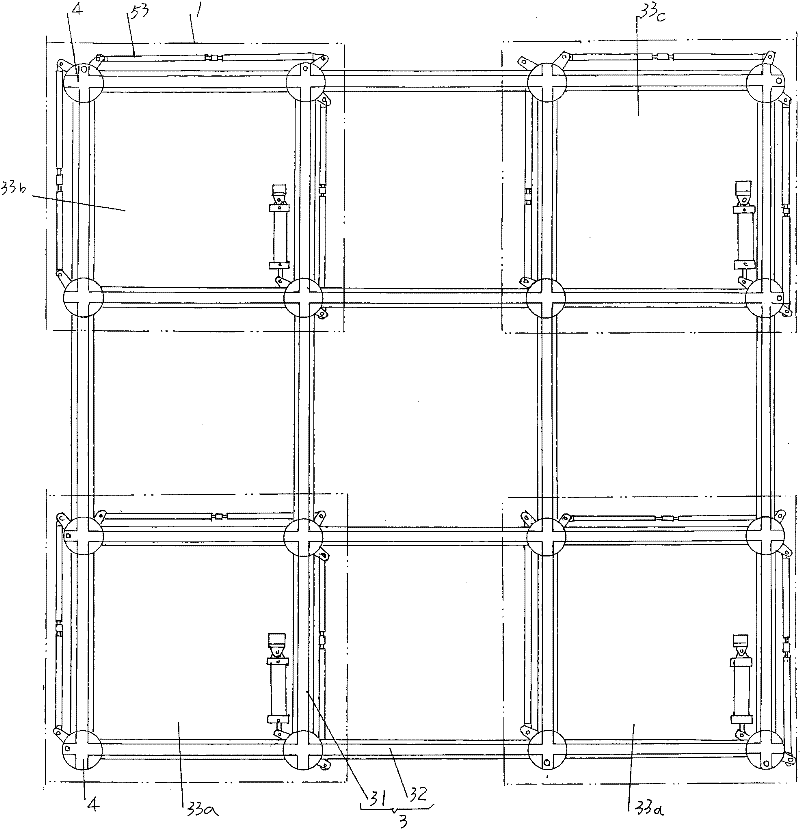

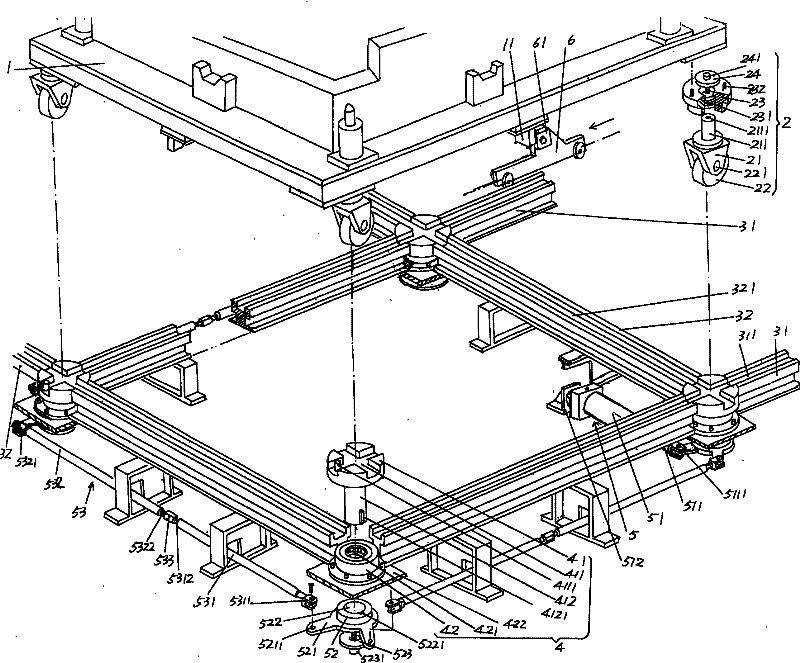

[0021] Please see figure 1 with figure 2 , see first figure 2, the track assembly 3 is composed of four longitudinal guide rails 31 parallel to each other and four transverse guide rails 32 parallel to each other, that is to say, there are two pairs of longitudinal and transverse guide rails 31, 32, and each pair is two. The longitudinal and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap