Priming processing method and priming processing device

A technology for starting filling and treatment methods, applied in the direction of pretreatment of surfaces, devices for coating liquids on surfaces, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0052] Structure of the start-up filling processing unit

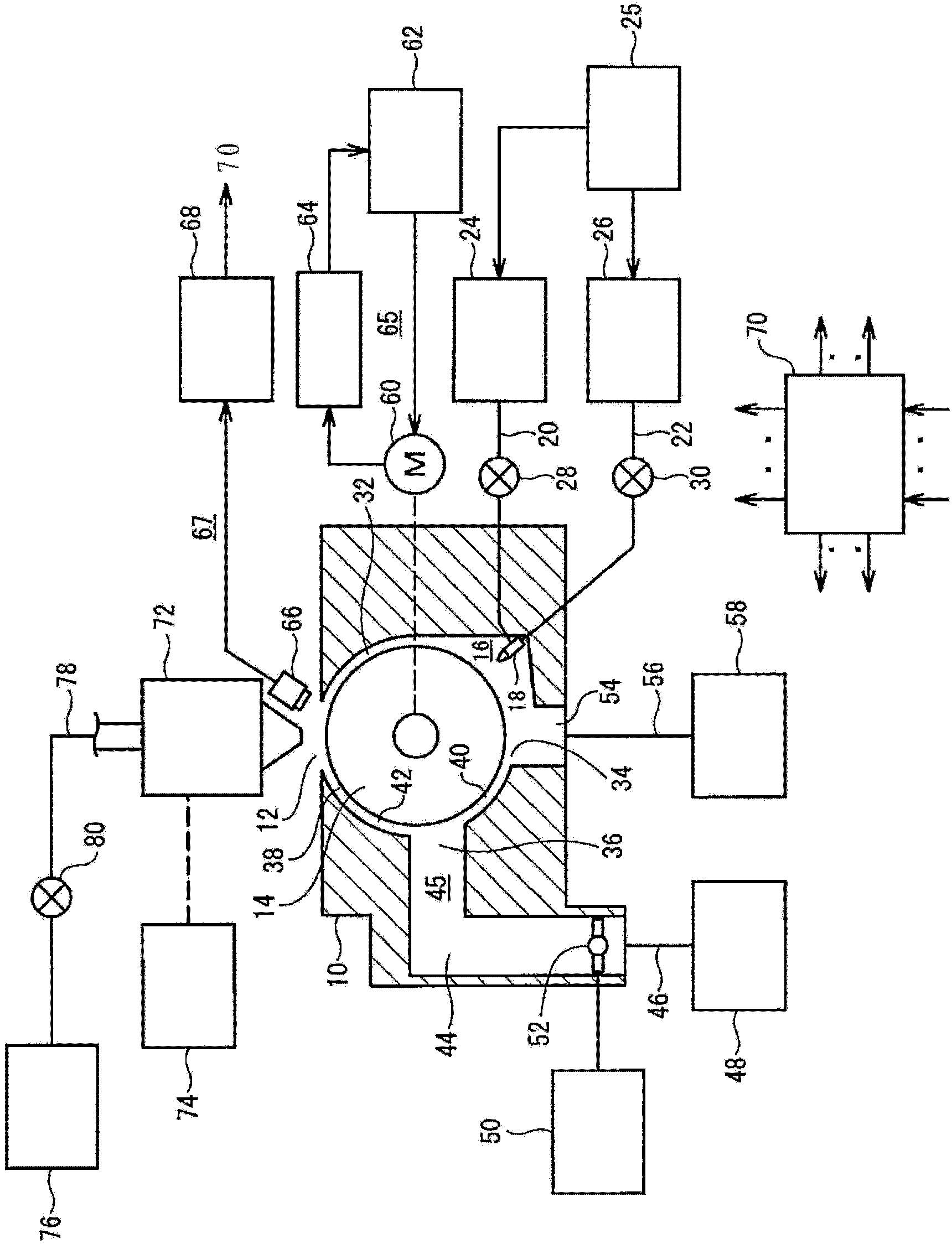

[0053] figure 1 The configuration of the priming processing device according to one embodiment of the present invention is shown. This priming processing device is incorporated in, for example, a resist coating device (not shown) that performs a non-rotational resist coating process in a photolithography process for LCD manufacturing process (not shown), and is placed in a In the resist coating process, the substrate to be processed is placed or floated in the vicinity of a coating table (not shown).

[0054] In the illustrated priming processing device, the casing 10 is constituted by a long frame having a slit-shaped opening 12 on the upper surface, and the top of the accommodated priming roller 14 passes through the opening 12. The form exposed above is horizontally and rotatably supported by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com