Improvement on grass-mowing head kinking structure

A technology of cutting grass head and thread winding, applied in the field of grass cutting head, which can solve the problem that the grass cutting line cannot be stretched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

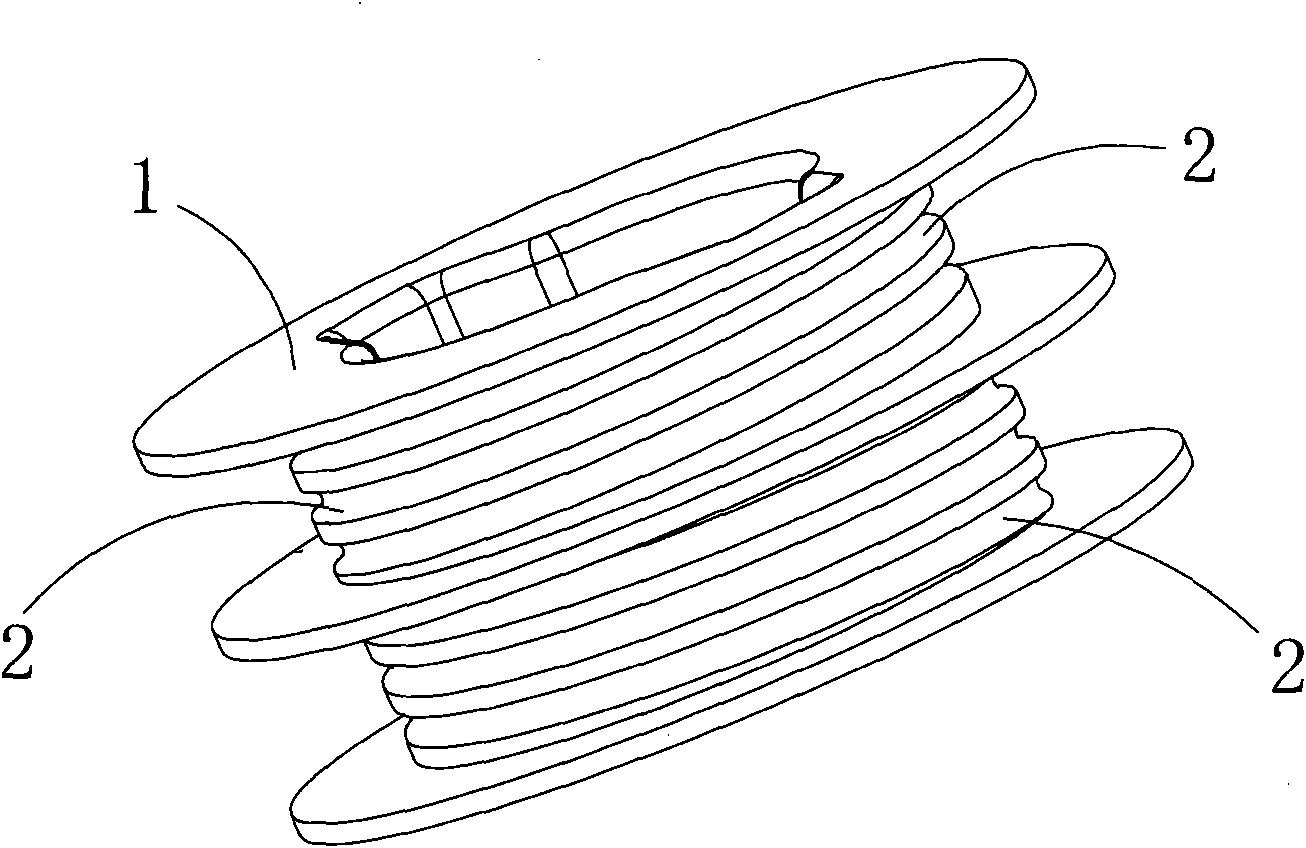

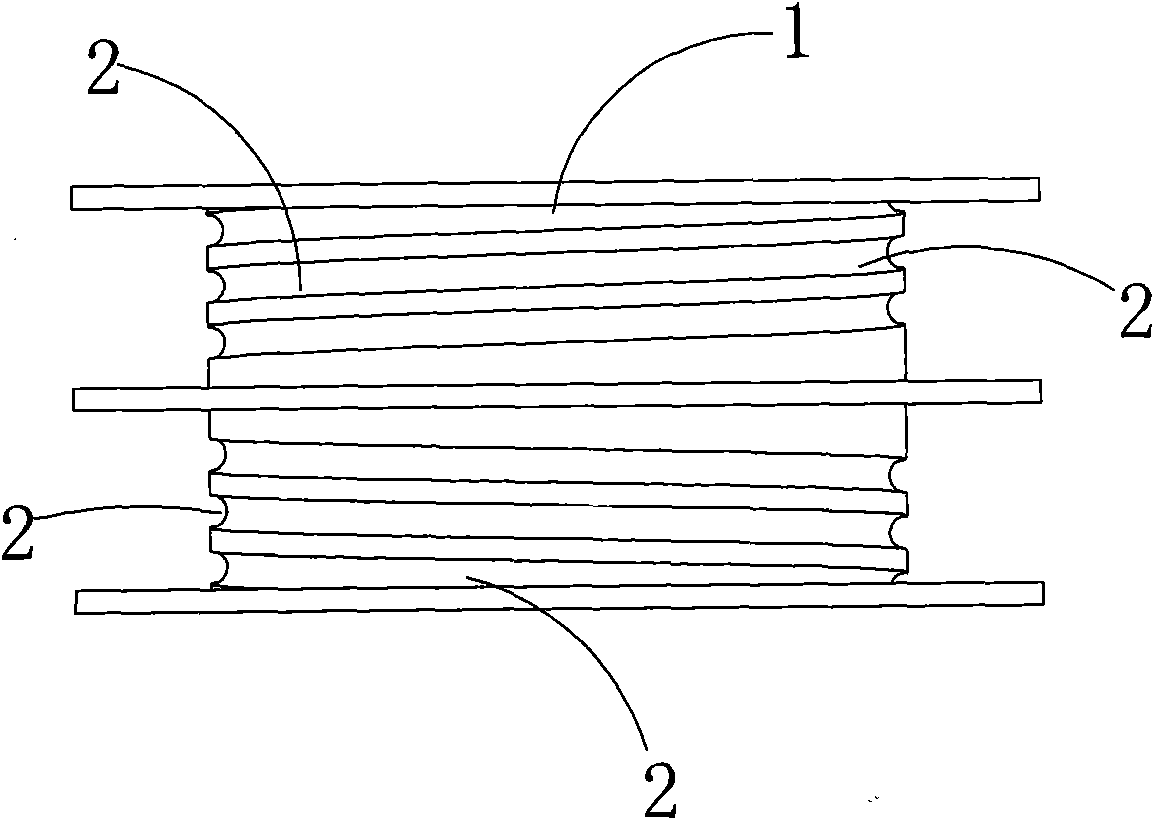

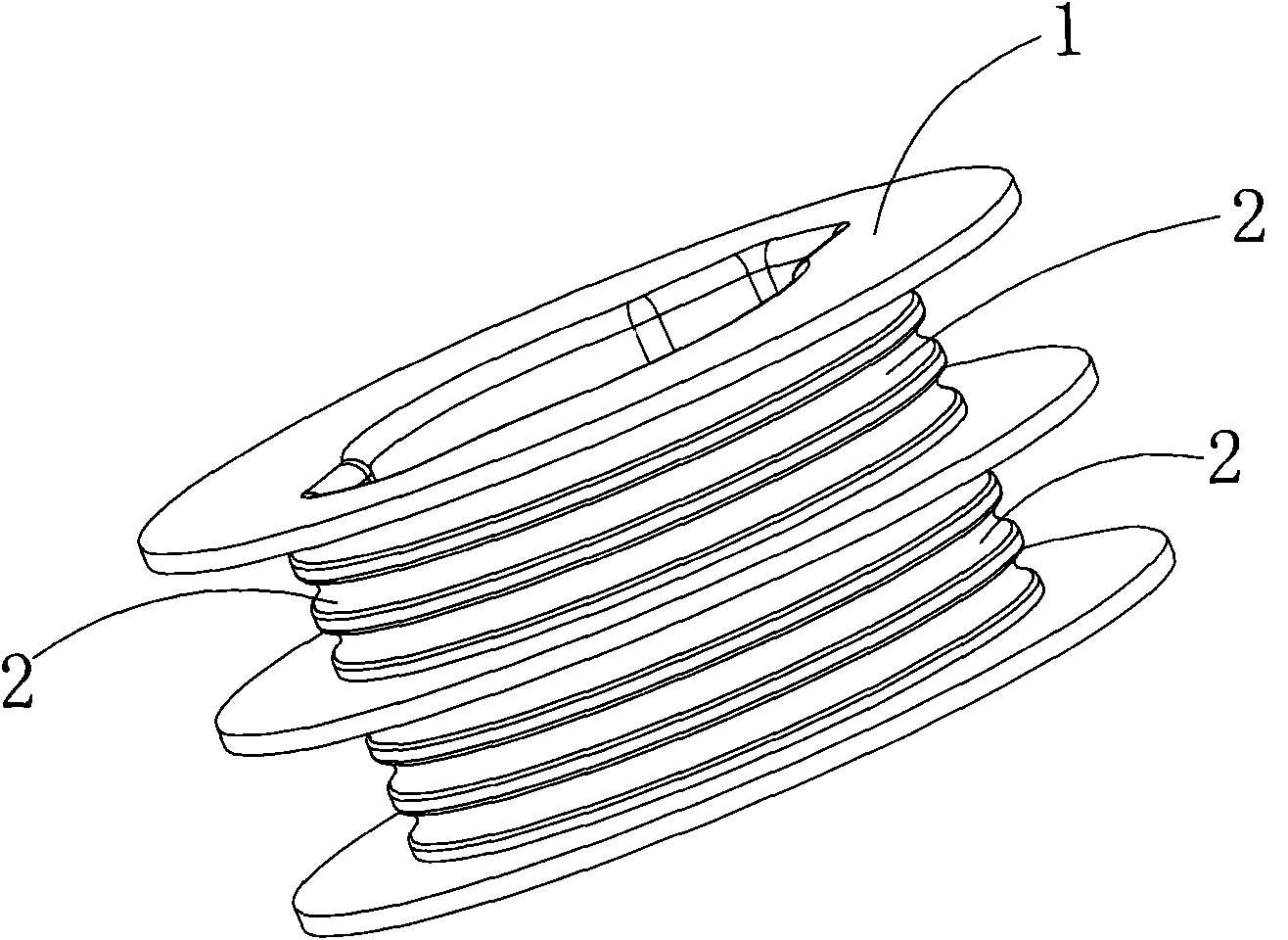

[0015] Embodiment: An improvement of the winding structure of the mowing head. There are several radial winding grooves 2 at the winding position on the winding core 1 inside the mowing head, and the grooves of all the winding grooves form the mowing line The winding path, the mowing line is embedded in the winding groove. Since the grooves of all the wire winding grooves constitute the winding path of the mowing wire, the mowing wire is embedded in the wire winding groove for winding, which does not hinder the winding of the mowing wire, and can also separate the wound mowing coil from the coil , to solve the problem that the mowing line cannot be stretched due to centrifugal force when the mowing head rotates at high speed.

[0016] The cross-sectional shape of the winding groove is any one of semicircle, ellipse, square, U-shape and V-shape.

[0017] The center distance between axially adjacent winding grooves is 2-6mm.

[0018] The winding path may be several radial circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com