Motor flexible lock body

A telescopic lock and lock shell technology, applied in non-mechanical transmission-operated locks, construction locks, construction, etc., can solve the problems of inability to achieve automatic locking, inability to be used more widely and multiple locks under one control, and achieve a wide range of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

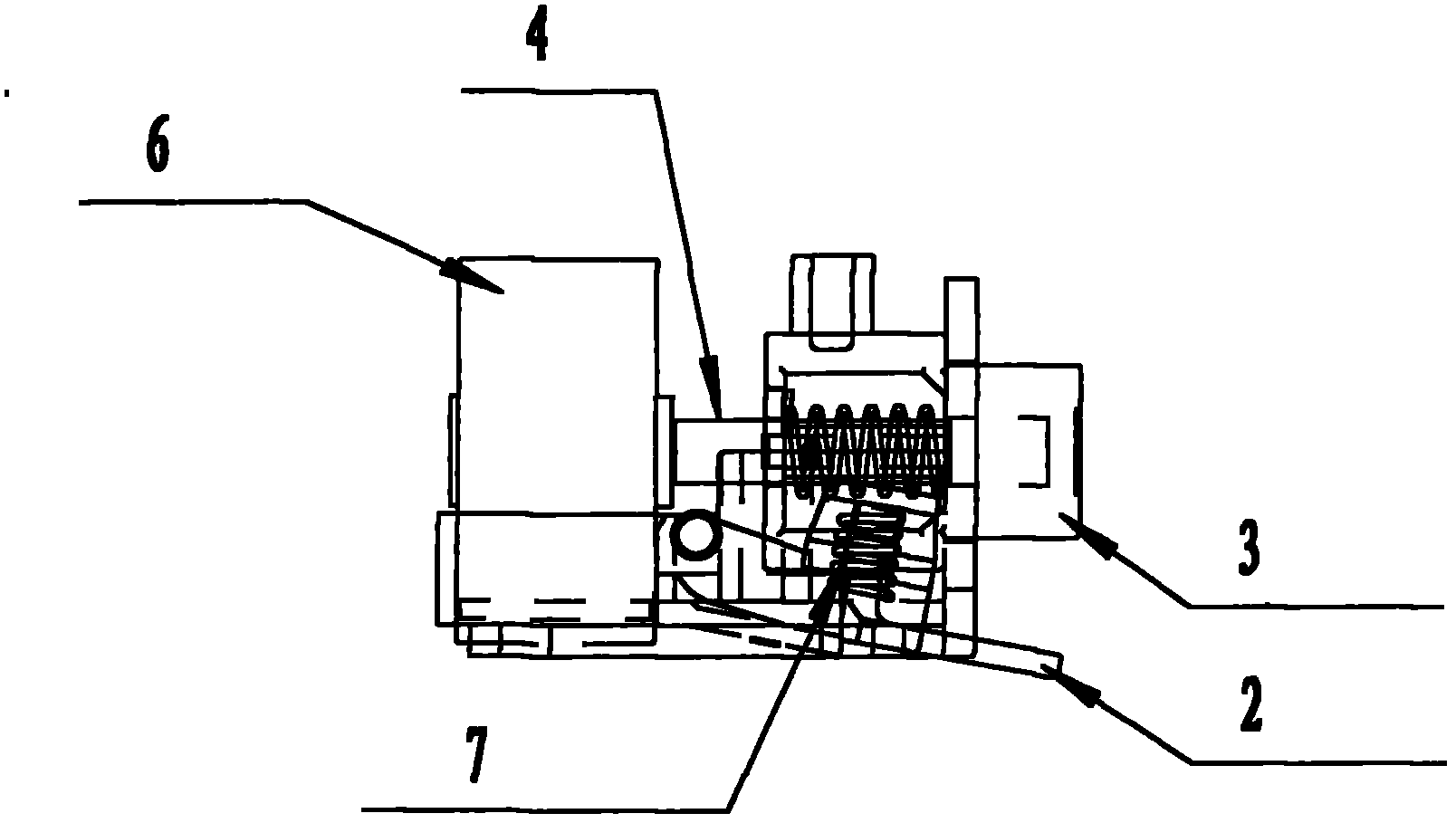

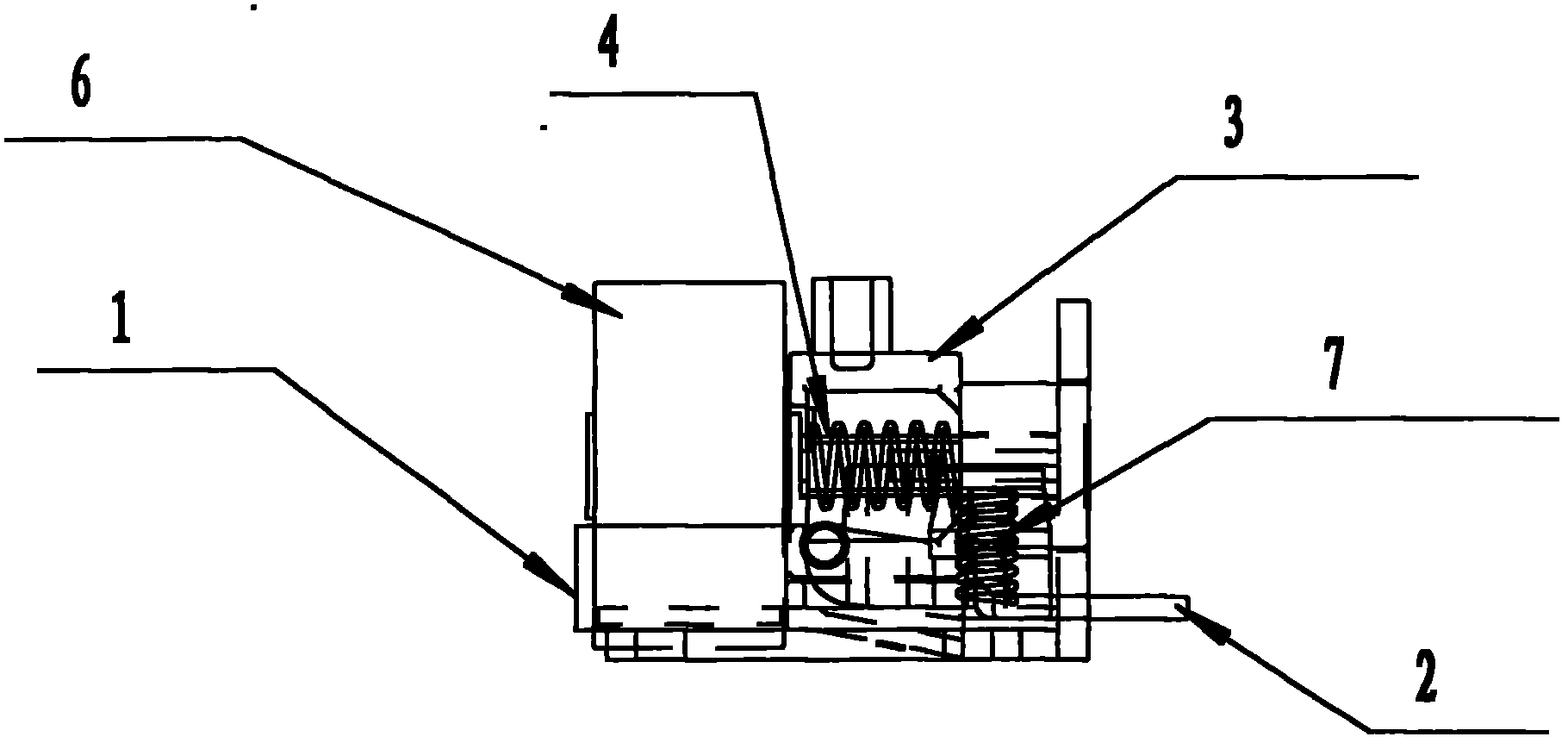

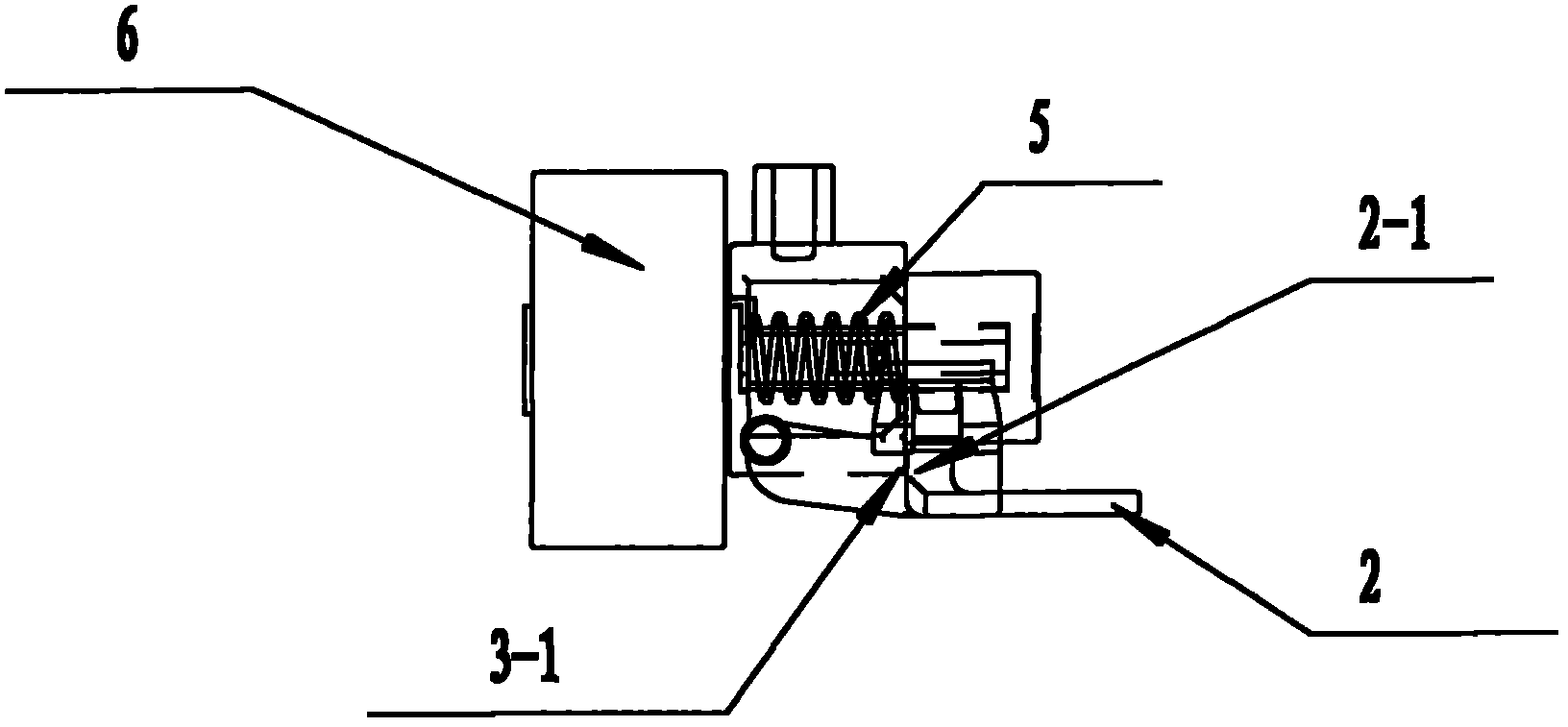

[0017] As shown in the figure, this motor retractable lock body mainly includes a lock case 1, a dead bolt 3 and a motor 6, the motor 6 is connected with the main shaft 4, and the main shaft 4 is equipped with a track spring 5, and the two parts of the track spring 5 The end is stuck in the inner frame of the lock tongue 3, and the shaft pin 4-1 matched with the track spring 5 is arranged on the main shaft 4; A backstop point 3-1 is provided, a backstop block 2-1 cooperating with the backstop point 3-1 is arranged on the lock catch 2, and a return spring 7 is arranged between the lock buckle 2 and the dead bolt 3.

[0018] Work steps:

[0019] 1. From the locked state to the unlocked state: load the motor 6 with current to rotate, drive the main shaft 4, and make the shaft pin 4-1 rotate, under the limit position of the track spring 5, let the lock tongue 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com