Pneumatic vehicle tire

A technology for vehicles and tires, which is applied to vehicle parts, tire parts, tire treads/tread patterns, etc., can solve problems such as weakening tire hydroplaning behavior, and achieve good friction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

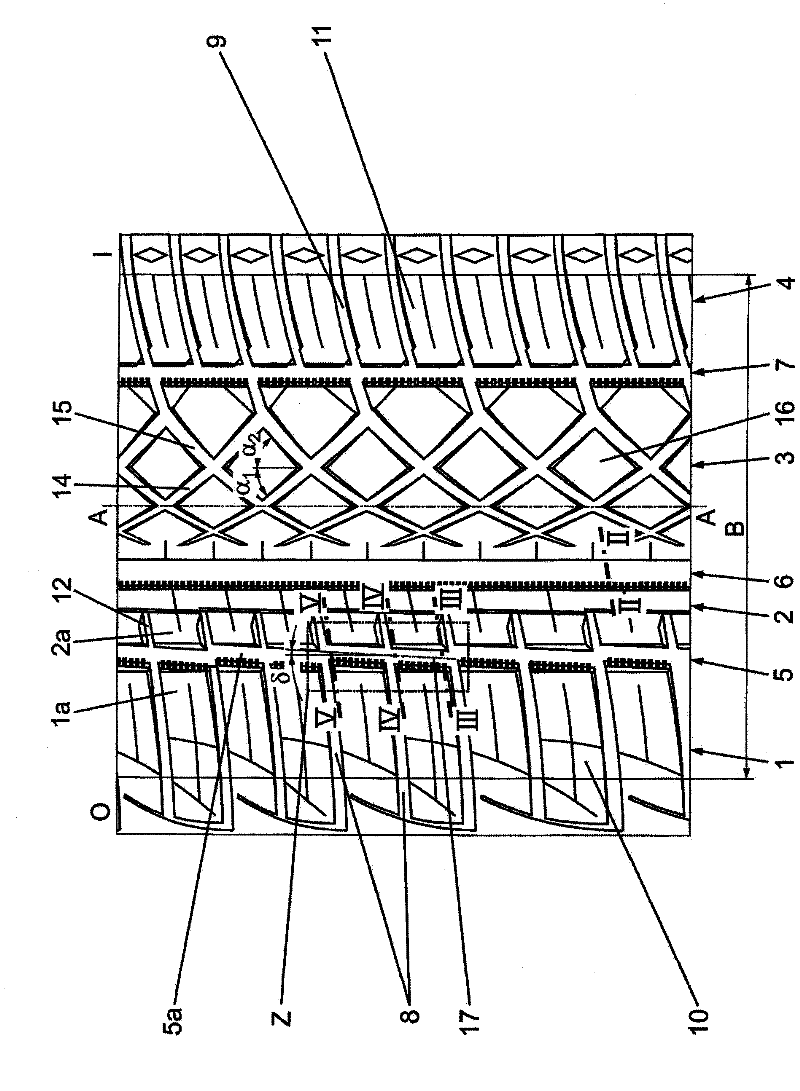

[0050] figure 1 An asymmetrical tread rubber pattern is shown for a radial type passenger car tire, which pattern is particularly suitable for year-round use. exist figure 1 Among them, A-A represents the central equatorial plane or equator line, which divides the tread rubber into two halves, and B represents the tread when a tire with this tread rubber is mounted on the rim and is in normal operating condition The contact width of the rubber, O denotes the outer shoulder, which is located on the outside when the tire is mounted on the vehicle, and I denotes the inner shoulder facing the center of the vehicle.

[0051] like figure 1 As shown, the pattern of the tread rubber (from the outer shoulder O to the inner shoulder I) has a row of tread blocks 1, a circumferential rib 2, a wide tread band 3, the wide tread The band occupies approximately 40% of the contact width B, extends around in the circumferential direction and is divided into a plurality of tread blocks 16 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com