Internal combustion heat engine, control system, method for dimensioning the engine, and automobile with said engine

A technology for internal combustion engines and control systems, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve problems such as non-optimized use of injected fuel, and achieve the effect of avoiding knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

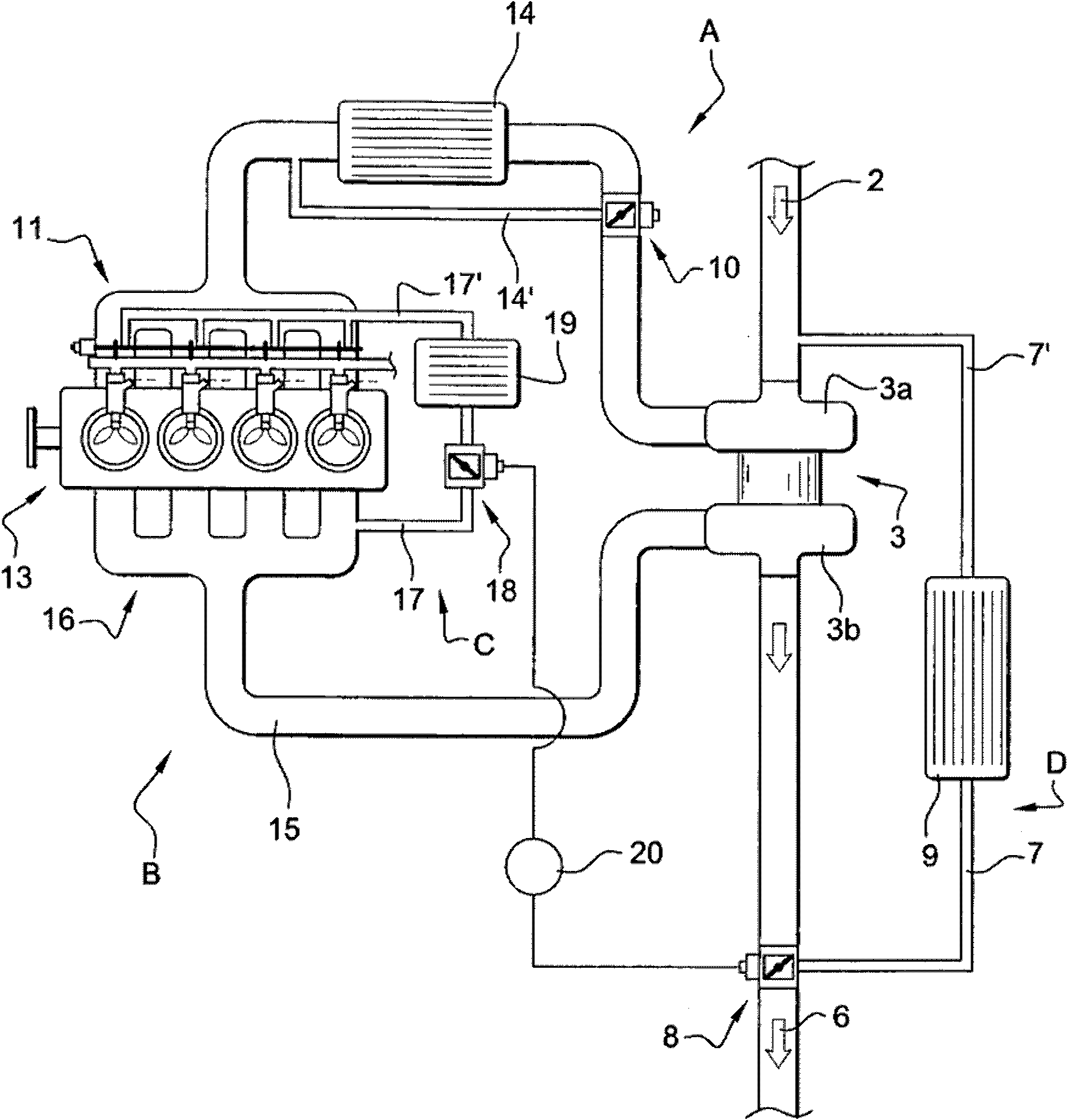

[0031] refer to figure 1, shows a supercharged engine 13 comprising four cylinders - all forming combustion chambers - supplied with intake gas through an intake circuit A, which is attached to the engine by an intake duct 11 and which is connected to in particular An exhaust circuit B including an exhaust manifold 16 is used to exhaust combusted gases. Fresh gas is delivered to the engine through the intake duct 2, then compressed by the compressor 3a of the turbo compressor 3, and delivered to the intake duct 11; the compressor 3a is mechanically connected to the turbine 3b. Exhaust gas leaving the exhaust manifold 16 is driven via the exhaust duct 15 towards the turbine 3b of the turbocompressor 3 where it is expanded to supply the power necessary to drive the compressor 3a. The exhaust gases can then be discharged or recirculated through the exhaust duct of the vehicle via pipe 6 .

[0032] Two independent exhaust gas recirculation (EGR) devices are provided: high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com