Fitting

A technology of pipe joints and connecting pipes, applied in the field of pipe joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

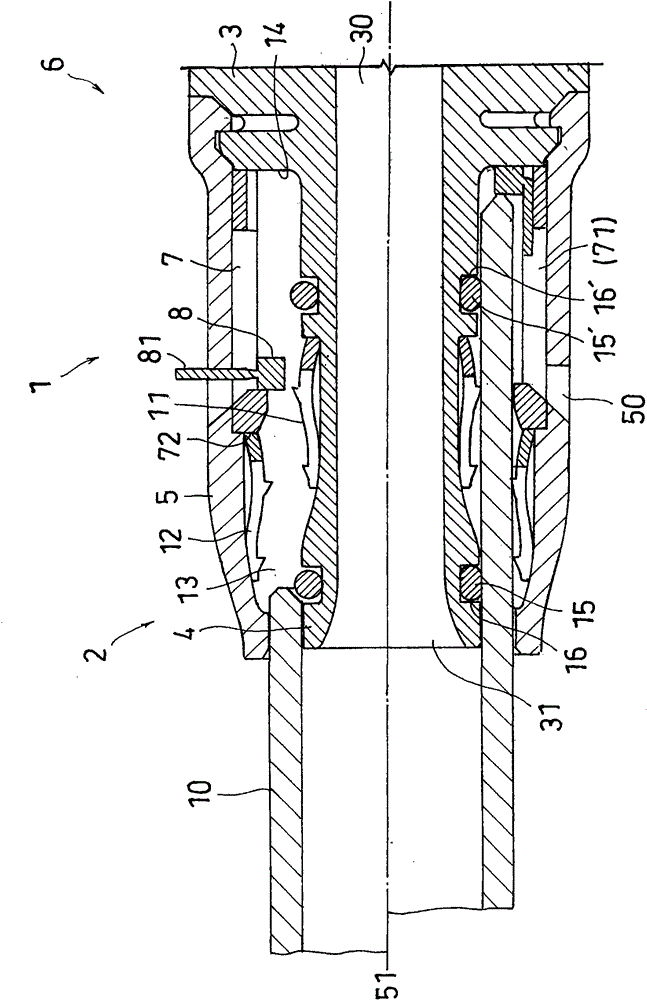

[0133] figure 1 It shows the in-line pipe joint 1 of a preferred embodiment of the present invention provided with the connecting tube insertion confirming mechanism 6, the upper half shows the state before the connecting tube is inserted, the lower half shows the state after the connecting tube is inserted, and A cross-sectional view of a case cut through a section through its central axis. refer to figure 1 It can be seen that the pipe joint 1 of the present invention only needs to include at least one connecting pipe insertion socket 2, so its overall shape is not limited to I-shape, but can also be T-shape or cross-shape.

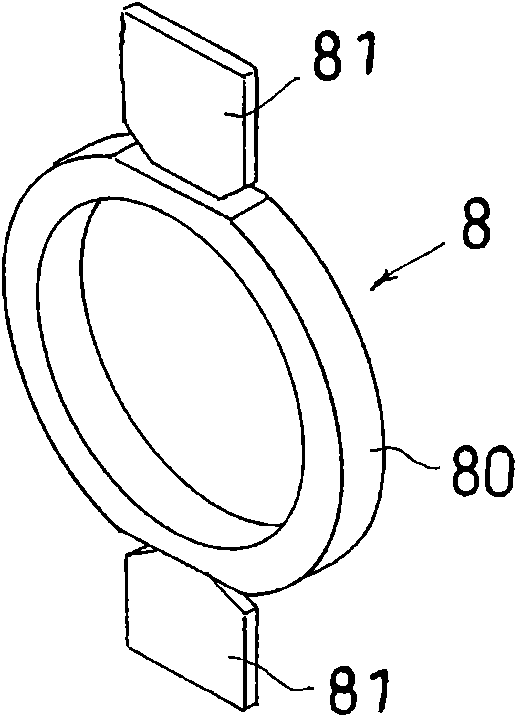

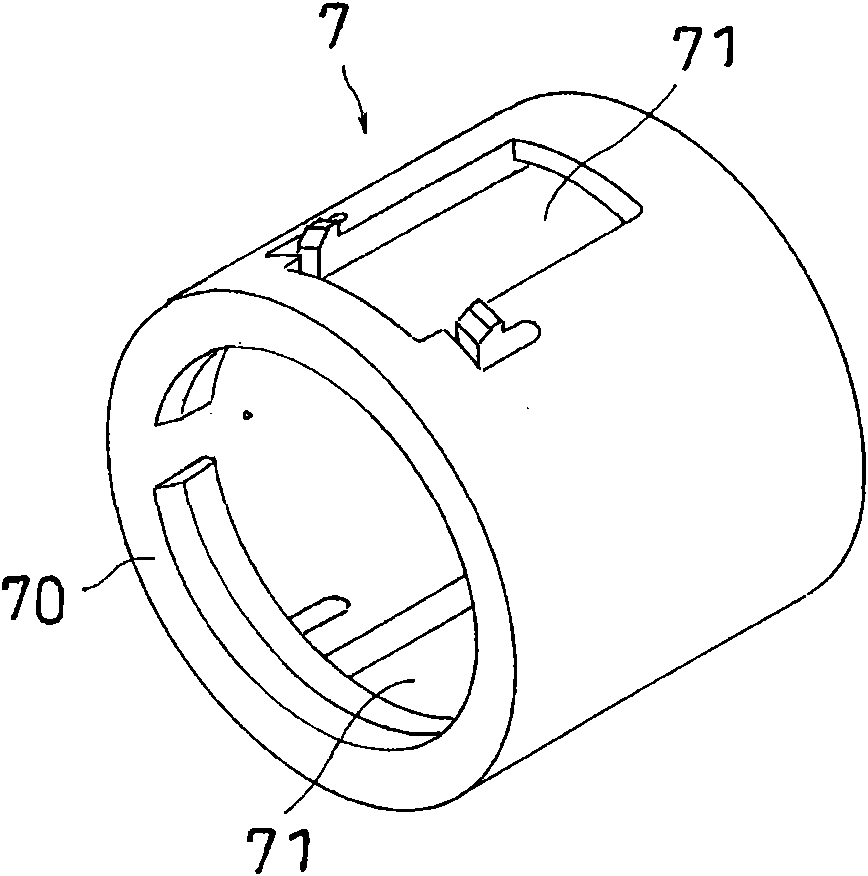

[0134] The pipe joint 1 includes a joint body 3 , an inner cylinder 4 , an outer cylinder 5 , an inner lock ring 11 and an outer lock ring 12 , and a connection tube insertion confirmation mechanism 6 , each of which has a substantially cylindrical or ring shape. In addition, in the first embodiment, the joint main body 3 includes the inner cylindrica...

Embodiment 2

[0165] Figure 10 It is an in-line connecting tube 1' according to another preferred embodiment of the present invention provided with a connecting tube insertion confirming mechanism 6. The upper half shows the state before the connecting tube is inserted, and the lower half shows the state after the connecting tube is inserted. And it shows the cross-sectional view of the case cut in the cross-section passing through the central axis. refer to Figure 10 It is understood that the pipe joint 1' of the present embodiment 2 has the same structure as the pipe joint 1 of the embodiment 1 except for the following points, the difference being that the locking ring 17 for locking the connecting pipe 10 has a radially extending A plurality of teeth or claws, and is an annular type lock ring fixed to the inner peripheral surface of the outer cylinder 5 .

[0166] Therefore, the pipe joint 1' of the second embodiment includes a joint main body 3, an inner cylinder 4, an outer cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com