Automobile engine hood hinge inspection tool

An engine cover and hinge technology, which is applied in the direction of using mechanical devices, mechanical measuring devices, force/torque/work measuring instruments, etc., can solve the problems of low detection accuracy, long detection period, and undetectable axis accuracy, and achieves the judgment structure. Accurate, compact fixture structure, and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

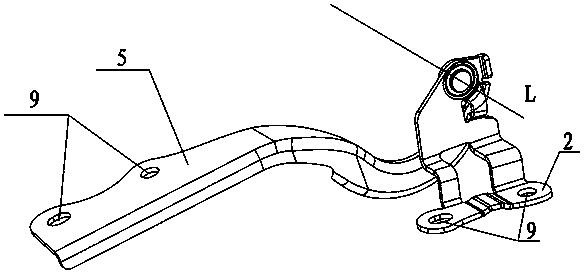

[0031] The inspection tool involved in the present invention is to detect or evaluate whether the relevant design of the automobile bonnet hinge meets the standard requirements, by figure 1 As can be seen, the structure of the existing automobile bonnet hinge mainly includes two parts: one is a bracket 2 for connecting the vehicle body, which has two mounting holes 9, one of which is a round hole, One is an oblong hole, and the oblong hole is mainly used to compensate the error in the direction of the connecting line between the two holes; the other part is used to connect the hinge arm 5 of the engine compartment cover assembly, which also has two mounting holes 9, and the two mounting holes 9 is also an oblong hole and a round hole. The upper and lower end faces of the two mounting holes 9 of the hinge arm 5 are a plane, which ensures that when the mounting hole 9 is connected to the engine compartment cover assembly, it is connected to the engine compartment cover. The fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com