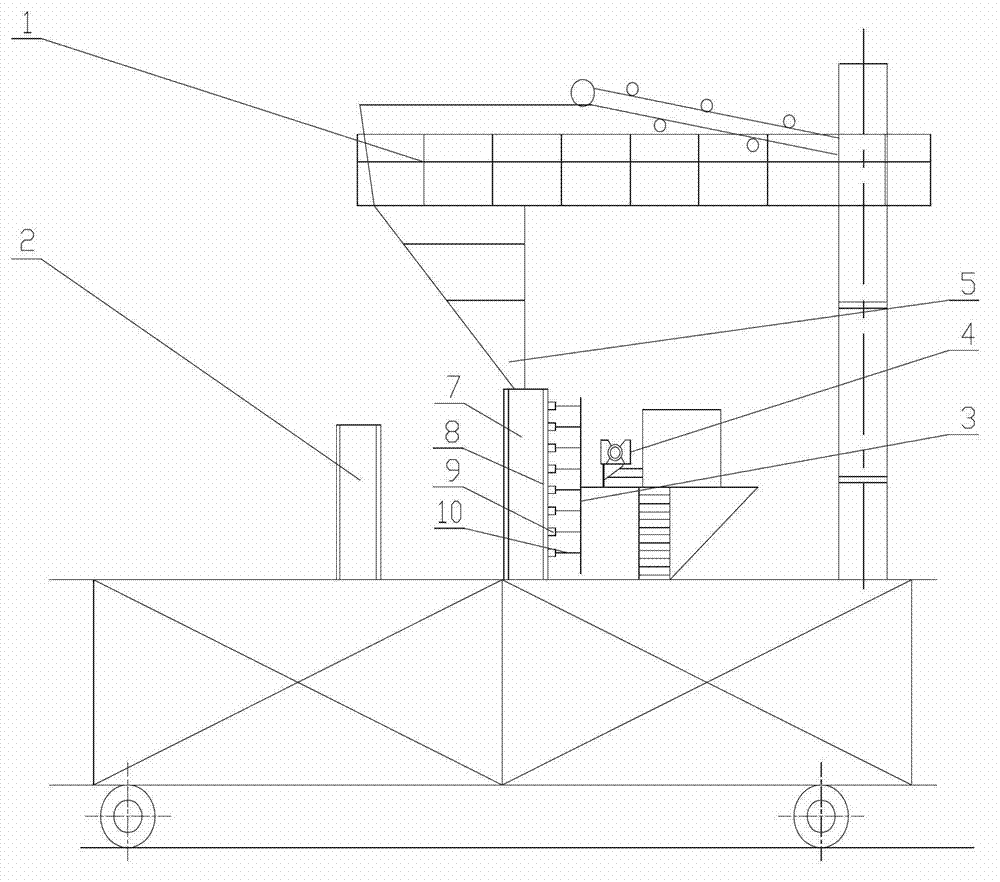

Lateral tamping device applicable to large-size coke furnace and lateral tamping method

A coke oven and large-scale technology, applied in coke ovens, charging devices, charging/unloading combined devices, etc., can solve problems such as increased coke oven height, increased weight of tamping hammer equipment, and reduced tamping efficiency, achieving Improve tamping efficiency, simplify coking tamping process, and overcome the effect of tamping efficiency decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

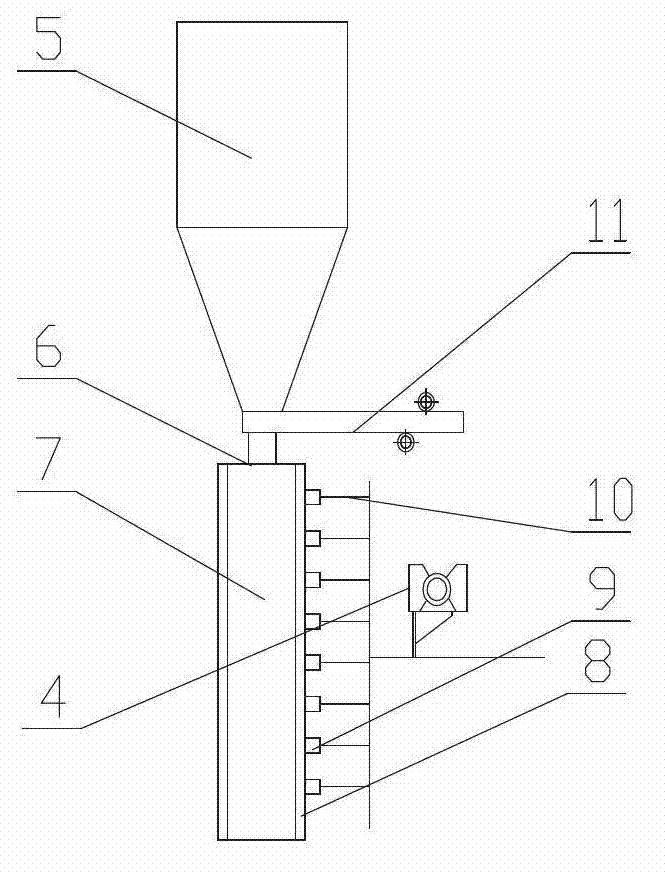

Embodiment 1

[0028] 10 rows of pressure heads are evenly distributed outside the movable side wall on one side of the coal cake box, and the distance between the two pressure heads of each row of pressure heads is 1000mm. The lateral pressure of the coal cake is 0.06MPa, the tamping time is 8min, and the density of the formed coal cake is 958kg / m 3 .

Embodiment 2

[0030] 14 rows of pressure heads are evenly distributed outside the movable side wall on one side of the coal cake box, and the distance between the two pressure heads of each row of pressure heads is 1000mm. The side pressure of the briquette is 0.1MPa, the tamping time is 10min, and the density of the formed briquette is 1162kg / m 3 .

Embodiment 3

[0032] 14 rows of pressure heads are evenly distributed outside the movable side wall on one side of the coal cake box, and the distance between the two pressure heads of each row of pressure heads is 800mm. The side pressure of the coal cake is 0.12MPa, the tamping time is 8min, and the density of the formed coal cake is 1185kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com