Device for measuring dynamic leak-off of foam fracturing fluid and working method thereof

A foam fracturing fluid and measuring device technology, which is used in measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of inaccurate measurement results and no mention of dynamic fluid loss of foam fracturing fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

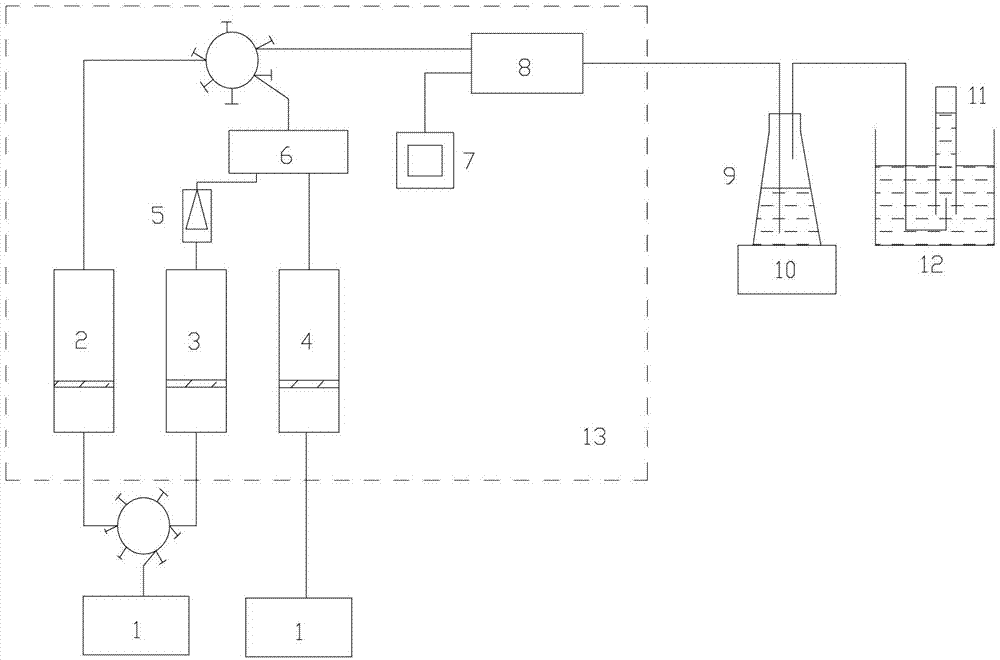

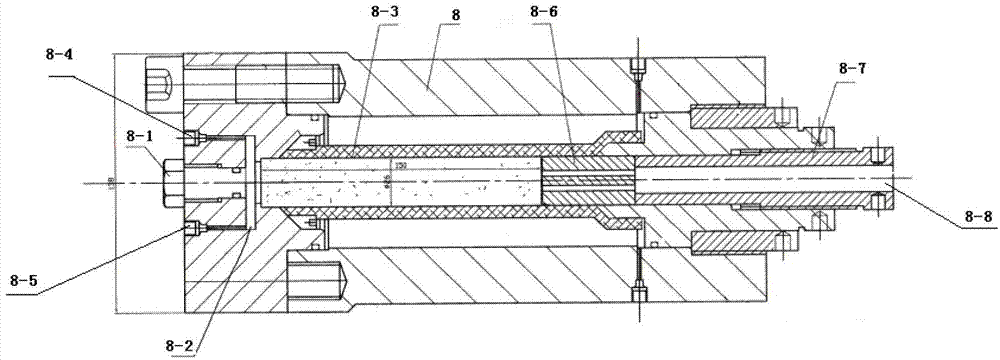

[0043] A device for measuring dynamic fluid loss of foam fracturing fluid, the device comprises an intermediate container 2 for holding standard brine, an intermediate container 3 for nitrogen gas, an intermediate container 4 for holding fracturing fluid and A core holder sleeve 8 containing a columnar core 8-3;

[0044] A simulated fracture 8-2 is provided at the inlet end of the core holder sleeve 8, a liquid inlet 8-4 is provided at one end of the simulated fracture 8-2, and a liquid inlet 8-4 is provided at the other end of the simulated fracture through a return The pressure valve 7 is connected with the liquid outlet 8-5, one side wall of the simulated crack 8-2 is connected with the plug 8-1, and the other side wall of the simulated crack is connected with the end face of the columnar core 8-3 , the other end face of the columnar rock core 8-3 is connected to the filter loss pipe 8-8 through a spacer 8-6 and a moving nut 8-6;

[0045] The intermediate container 2 for h...

Embodiment 2

[0048] The parameters of the columnar rock core used in the present embodiment are as shown in table 1:

[0049] Table 1: Parameter table of columnar core

[0050]

[0051] A method utilizing measuring device as described in embodiment 1 to measure dynamic fluid loss of foam fracturing fluid, comprising steps as follows:

[0052] (1) Determination of the gas permeability K of the columnar core to be tested 1 ’ and weigh it;

[0053] (2) Determination of the porosity of the columnar core:

[0054] a. Evacuate the columnar rock core for 5 hours under the condition of vacuum degree of 0.1MPa;

[0055] b. Pressurize and saturate the columnar core with standard brine under formation pressure;

[0056] c. wipe off the water on the surface of the columnar core saturated with standard brine, weigh it, and calculate the porosity of the columnar core;

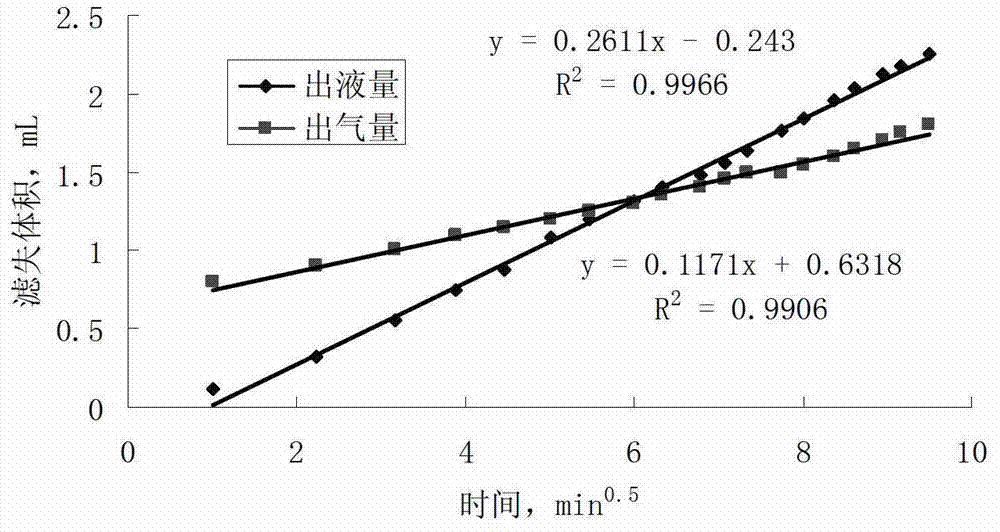

[0057] (3) Put the columnar core into the core holder sleeve, connect the pipeline, apply confining pressure to the columnar co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com