Flat bottom trenching machine

A trough forming machine and flat bottom technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of unallowable, high and uneven bottom of the trough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

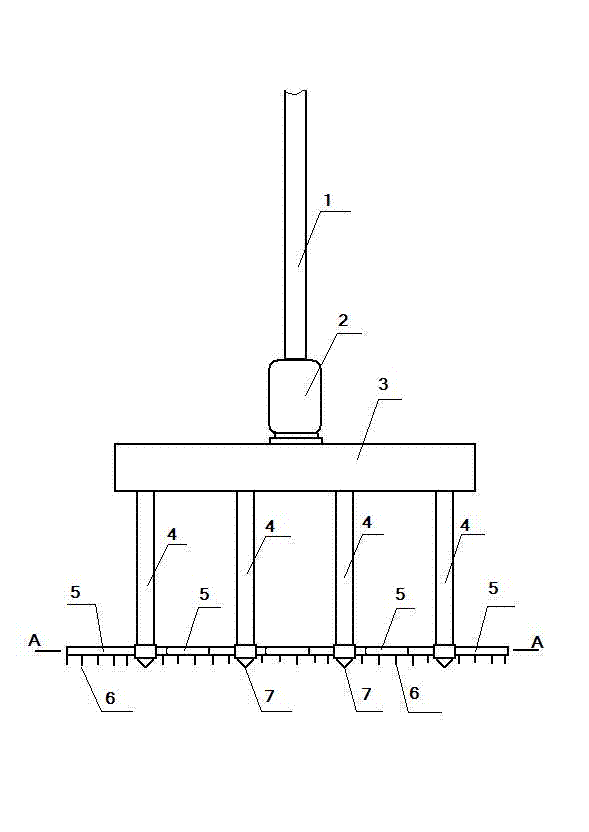

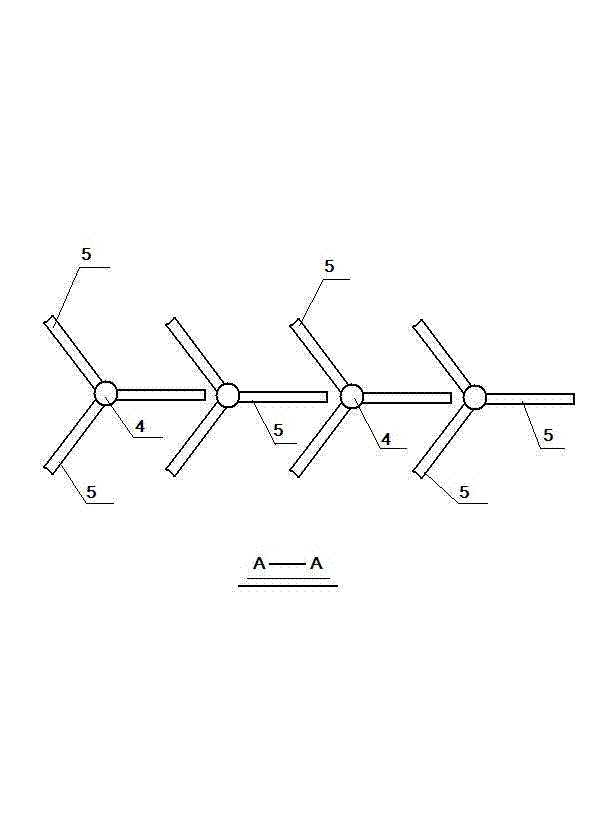

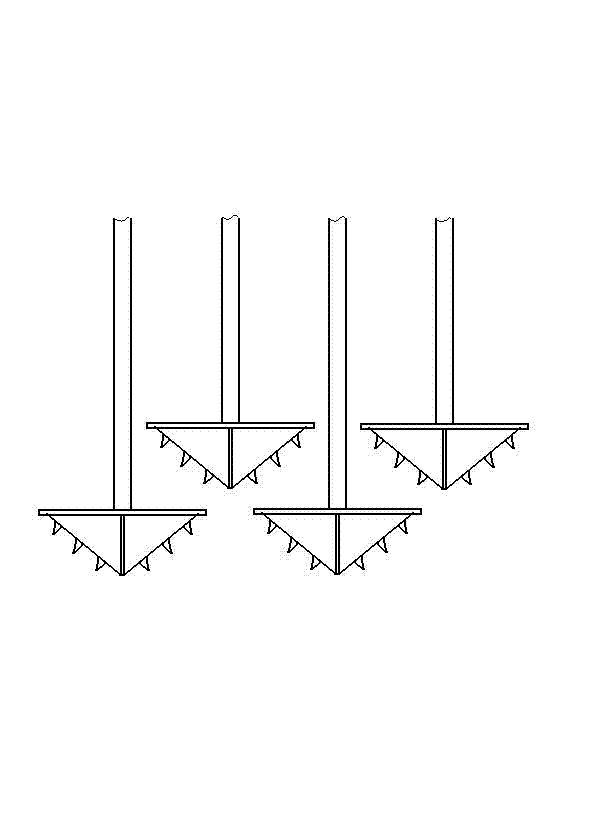

[0013] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment main drilling rod 1 lower end is provided with motor 2, and motor lower end is provided with gear box 3, and gear box lower end is provided with a plurality of drilling rods 4, and each drilling rod lower end is provided with There are three drill wings 5, and the three drill wings are in the same plane, and the angle between every two drill wings is 120°. The special feature is that every three drill wings under the multi-heel drill pipe are located on the same plane Inside, a drill wing of an adjacent drill rod is positioned between two drill wings of another drill rod.

[0014] When the present invention works, a plurality of drill rods rotate at a constant speed, wherein, the two drill rods on the left rotate forward, and the two drill rods on the right reverse. Rotate between two drill wings of another drill rod, and the drill wings do not fight with each other.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap