Novel bridge protecting facility

A technology for protective facilities and bridges, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of difficult guarantee of safety protection and difficult construction, and achieve the effect of easy anchoring, good stability, and safe passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

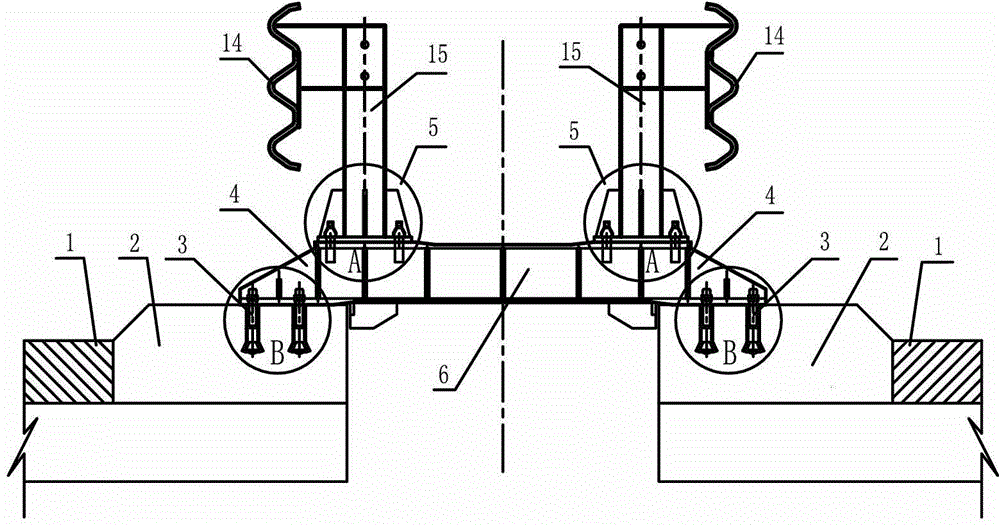

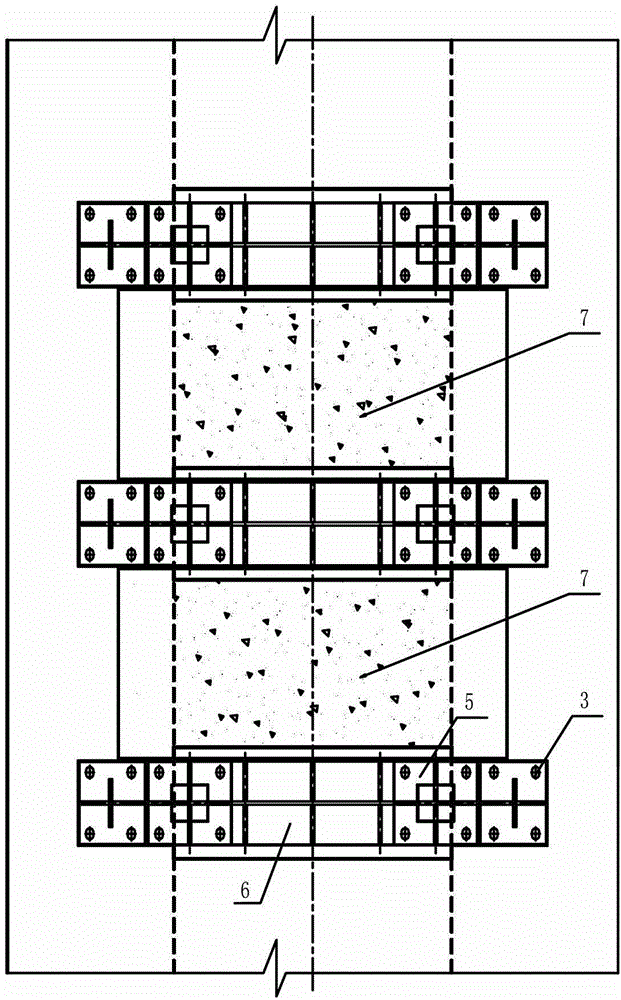

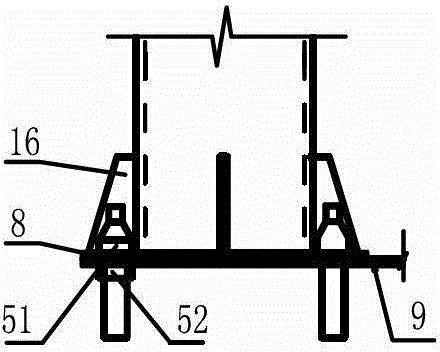

[0023] The length of the ground burden set at the bridge is 30m, its height is 30cm, and its width is 1m. The concrete grade used is C30. The bottom plate is welded by steel plates with a thickness of 20mm and 10mm respectively; 40mm×26mm connecting bolt holes are reserved at the corresponding positions of the top plate and the bottom plate to ensure that the connecting bolts pass through the top plate and the bottom plate to form anchorage; The limit steel plates are all made of steel plates with a thickness of 12mm; the positioning steel plates are made of 30mmx30mm shaped square steel; the prefabricated steel beam components and ground burdens are connected and anchored by M24 post-embedded bolts; the prefabricated steel beam components and wave guardrail columns use M24 feet Bolt anchor. The invention has simple and convenient installation and reliable measures.

[0024] Construction process of the present invention is:

[0025] After processing the top plate 9, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com