Wedge side flanging device and cold stamping die

A cold stamping and rollover technology, applied in the field of manufacturing, can solve the problem that the inclined wedge rollover mechanism cannot meet the side flanging manufacturing of the side flanges of beam parts, and achieves a convenient follow-up maintenance, compact structure and simple manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

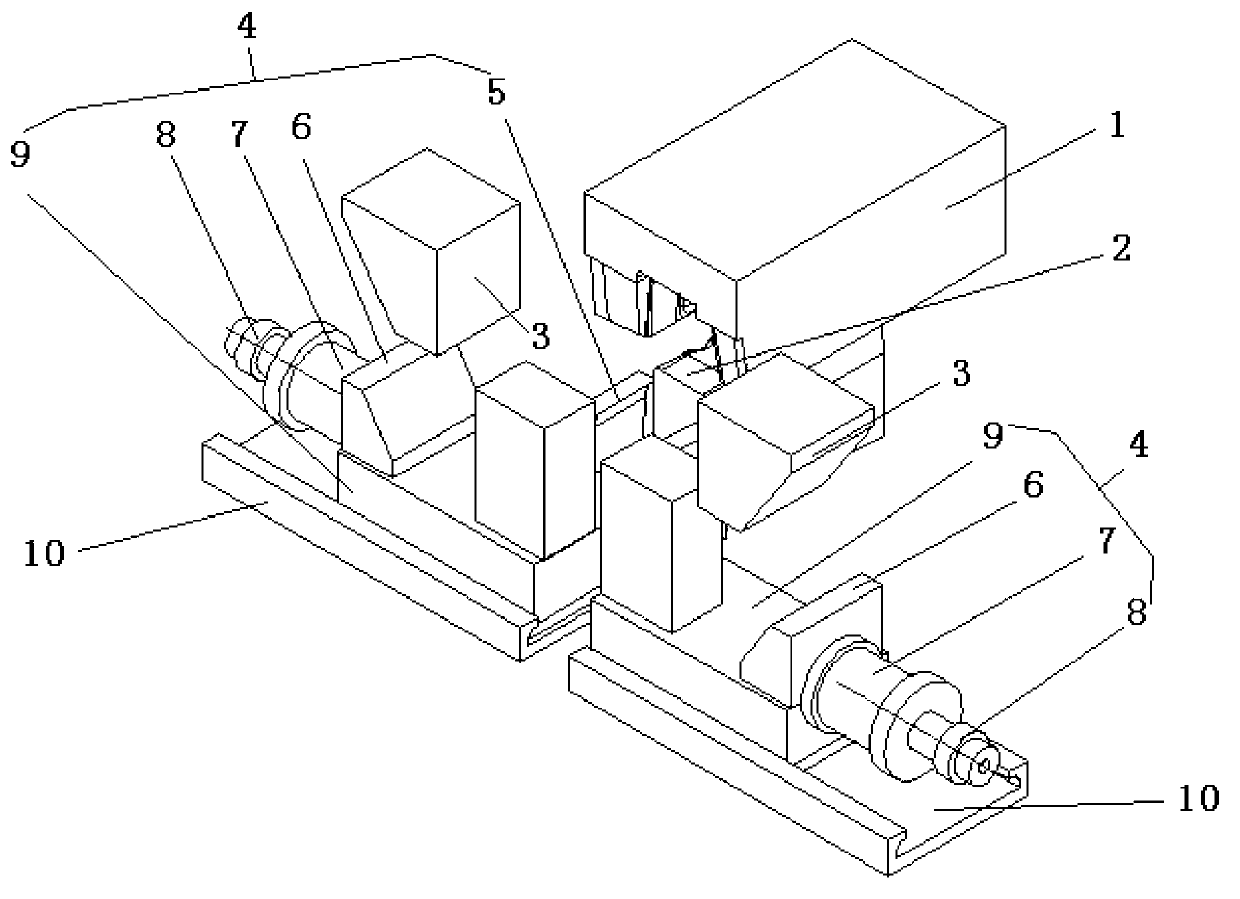

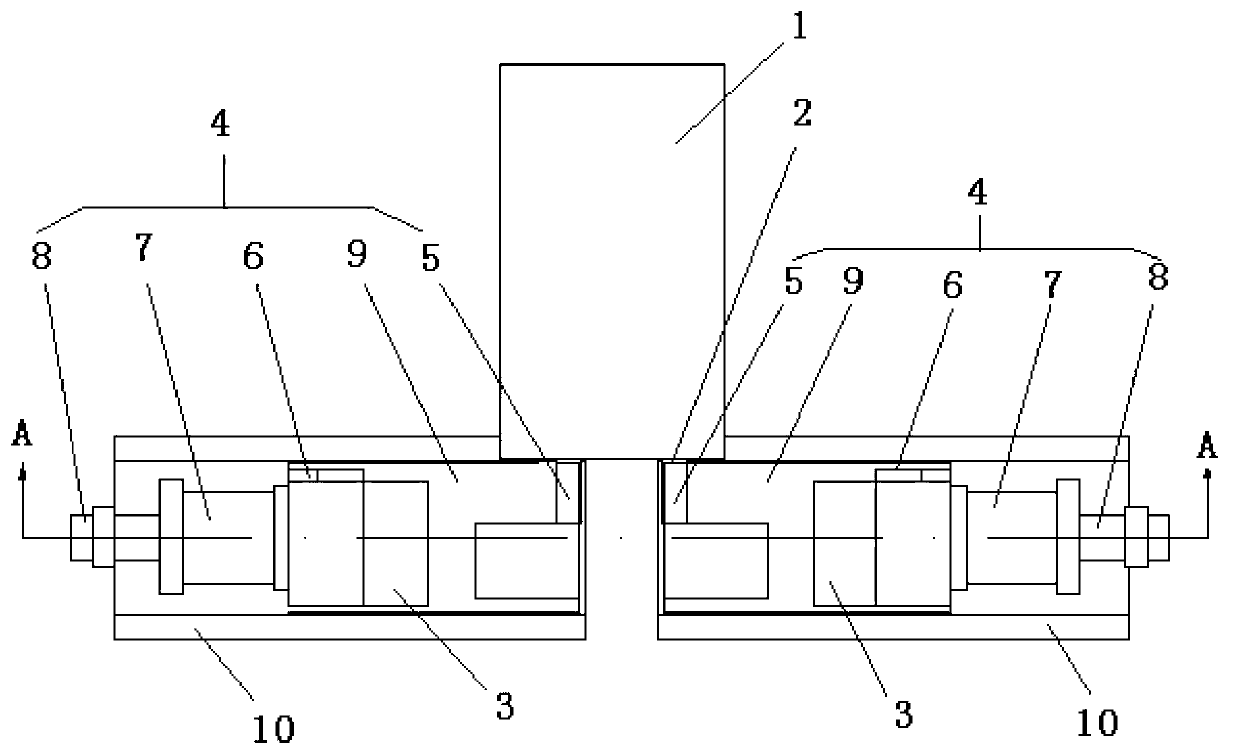

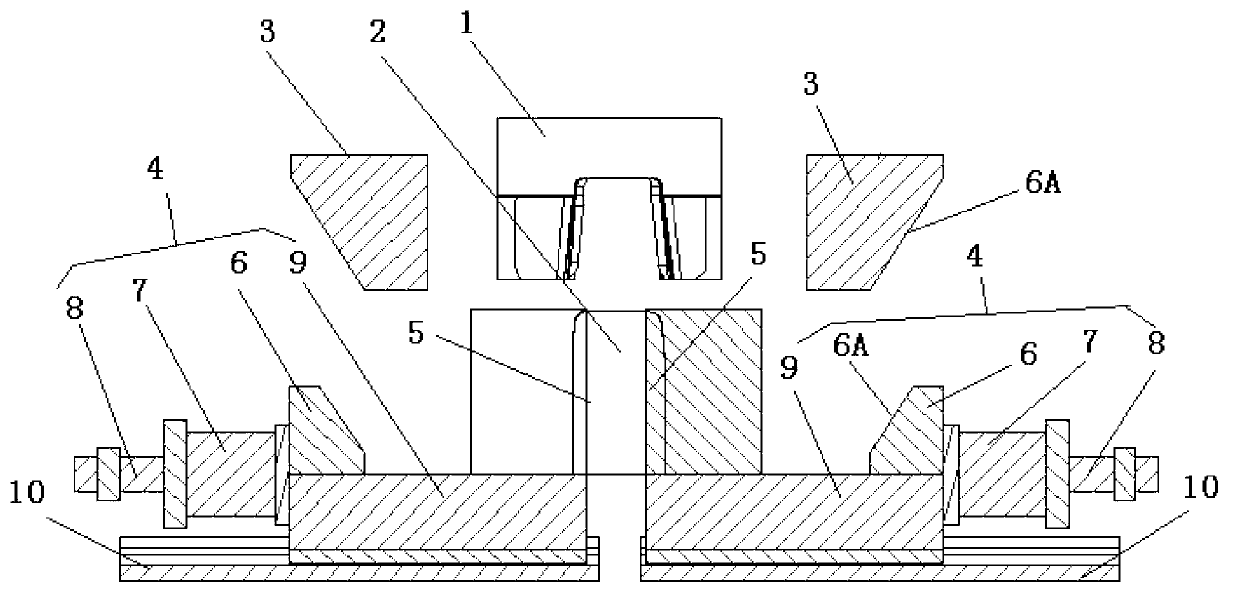

[0026] like Figure 1-3 As shown, this embodiment provides a pull wedge rollover device, and this embodiment uses figure 1 To illustrate mainly, the pull wedge rollover device is fixed between the upper mold body and the lower mold body, and the pull wedge rollover device includes a binder plate 1, a knife insert 3, a lower mold 2, a flanging mechanism 4 and Chute 10, the binder plate 1 is fixed on the upper mold body, the inserting knife 3, the flanging mechanism 4 and the chute 10 are all symmetrical structures, and they are all opposite to the binder plate 1 is symmetrical, the insertion knife 3 is fixed on the upper mold base, the lower mold 2 and the flanging mechanism 4 are fixed on the lower mold body, the flanging mechanism 4 includes a driving part and a flanging knife block 5, The flanging knife block 5 is arranged under the binder plate 1, the insertion knife 3 and the driving part are arranged on the outside of the binder plate 1, and the driving part slides relat...

Embodiment 2

[0034] On the other hand, see Figure 1-3 , the embodiment of the present invention also provides a cold stamping die, the cold stamping die includes an upper die, an upper die body, an upper die seat, a lower die body and a pull wedge rollover device, and the pull wedge rollover device is fixed on Between the upper mold body and the lower mold body, the pull wedge rollover device includes a binder plate 1, a slotting knife 3, a lower mold 2, a flanging mechanism 4 and a chute 10, and the binder plate 1 is fixed on the On the upper mold body, the insertion knife 3, the flanging mechanism 4 and the chute 10 are all symmetrical structures, and they are all symmetrical with respect to the binder plate 1, and the insertion knife 3 is fixed on the upper mold base. The lower mold 2 and the flanging mechanism 4 are fixed on the lower mold body, the flanging mechanism 4 includes a driving part and a flanging knife block 5, and the flanging knife block 5 is arranged on the binder plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com