Detection instrument for automatically detecting longitudinal rigidity

A longitudinal stiffness and detector technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of difficulty in ensuring the consistency and accuracy of the test results, time-consuming and labor-intensive, etc., and reduce the cost of experiments. The effects of poor data reproducibility, improved accuracy, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

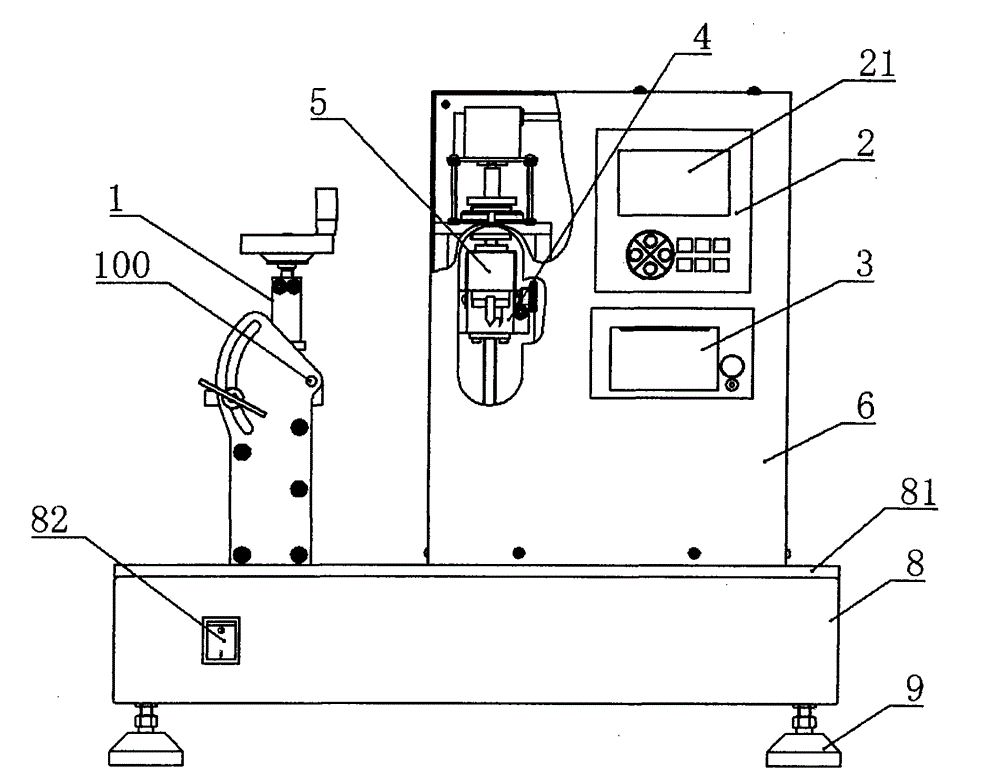

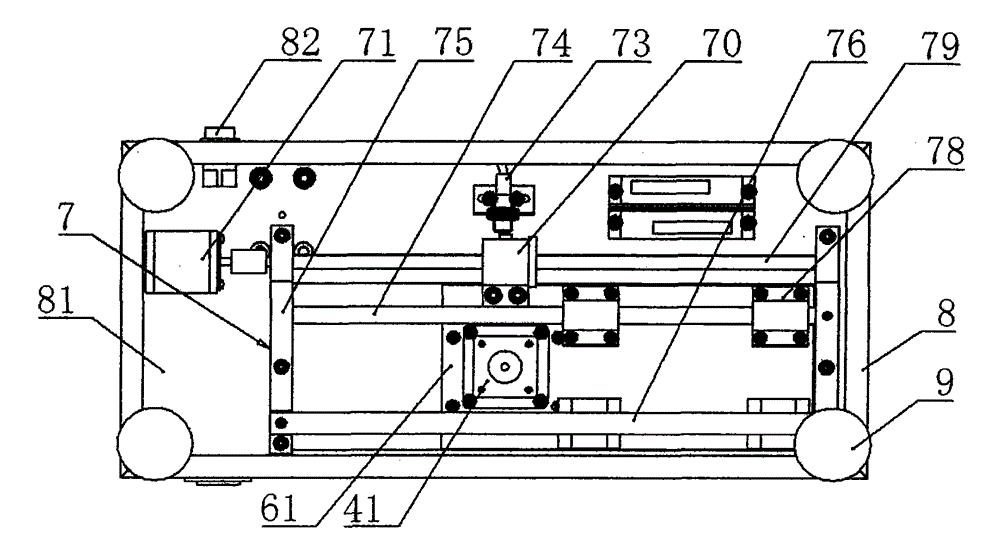

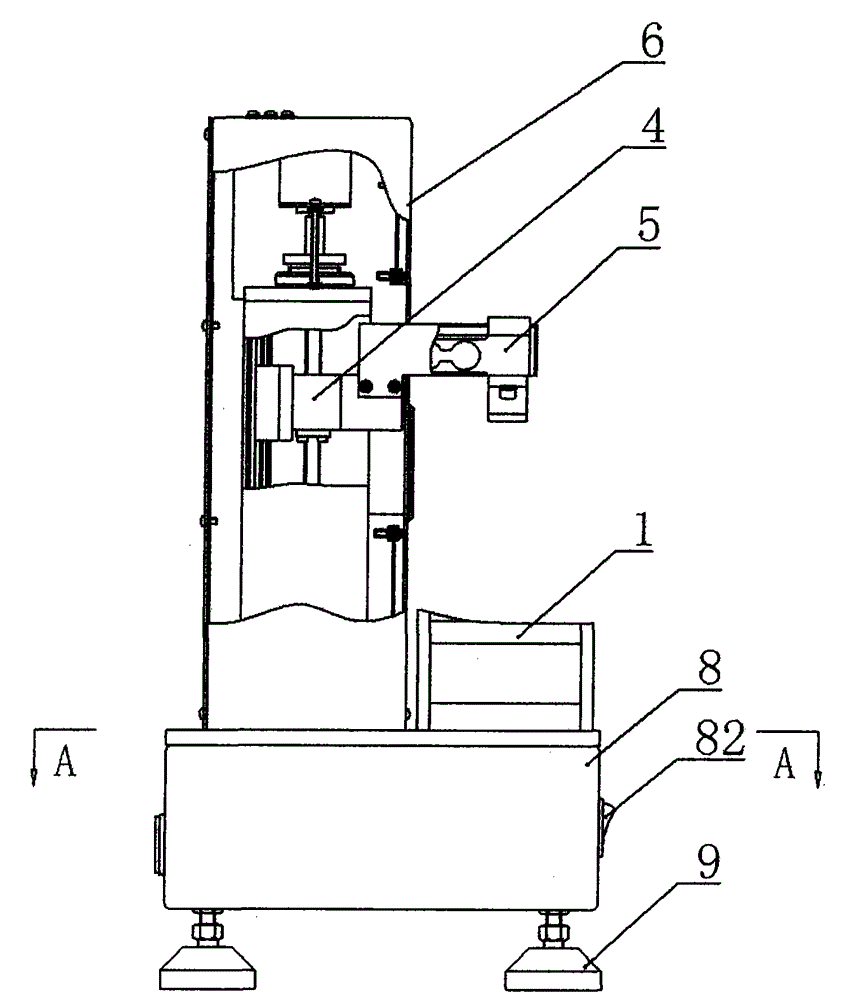

[0025] see Figure 1 ~ Figure 4 , the present invention is a detector for automatically measuring longitudinal stiffness, which is characterized in that it includes a base 8, a clamping mechanism 1, a lifting mechanism 4, a testing mechanism 5, a displacement mechanism 7 and a controller 2, and is mounted on the base 8 There are a clamping mechanism 1, a lifting mechanism 4 and a controller 2, a displacement mechanism 7 is installed in the base 8, the lifting mechanism 4 and the controller 2 are installed in a box 6, and the bottom end of the box 6 is connected to the displacement mechanism 7 up and able to move left and right. The testing mechanism 5 is connected to the upper part of the lifting mechanism 4 . The clamping mechanism 1 , the lifting mechanism 4 , the testing mechanism 5 and the displacement mechanism 7 are all electrically connected with corresponding interfaces of the controller 2 .

[0026] The four corners of the bottom end of the base 8 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com