A two-stage buffer type anti-hammer coaxial valve

A coaxial valve, stage technology, applied in valve details, multi-port valves, valve devices, etc., can solve problems such as inability to eliminate water hammer, high manufacturing costs, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

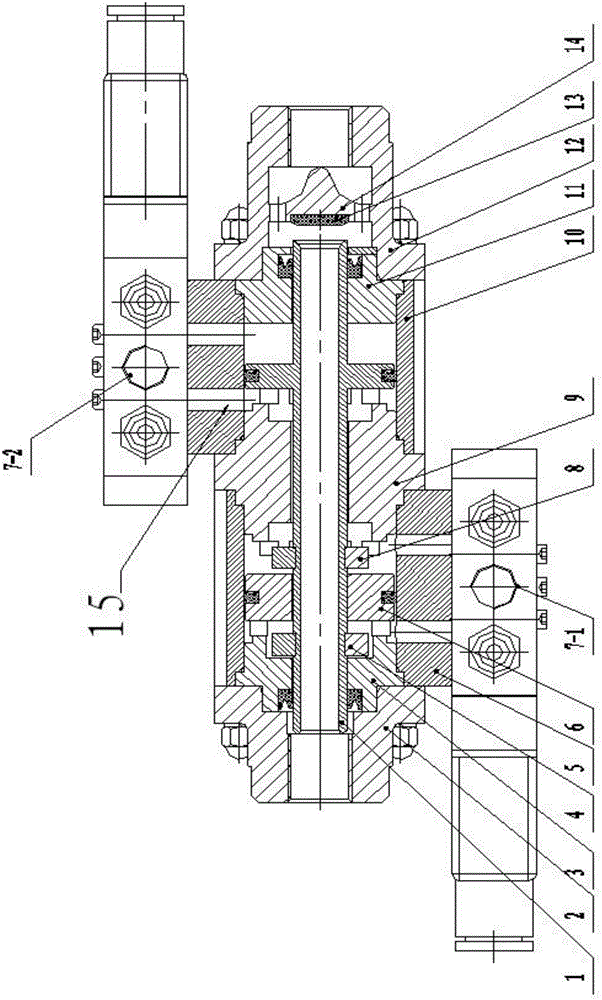

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a two-stage buffer type anti-hammer coaxial valve, a left bushing 3 is arranged between the left cylinder head 2 and the left cylinder body 5, and a middle cylinder head 9 is arranged between the left cylinder body 5 and the right cylinder body 10, A right bushing 11 is arranged between the right cylinder head 12 and the right cylinder body 10, and the inside of the left bushing 3 and the right bushing 11 are embedded with sealing rings. The left cylinder body 5 is equipped with a left piston 6 that can slide freely, and the left piston 6 handles the left cylinder. The inner cavity of the body 5 is divided into two parts, the left cavity and the right cavity. The spool 1 runs through the left cylinder 5 and the right cylinder 10. The inner cavity is divided into two parts, the left cavity and the right cavity. There are two air intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com