An automatic reversing insulin mixing device

An automatic reversing and insulin technology, which is applied to mixers with rotating containers, mixers, dissolving, etc., can solve the problems of insufficient supply of insulin, poor effect, and unequal mixing methods, so as to prevent automatic reset, simplify the structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

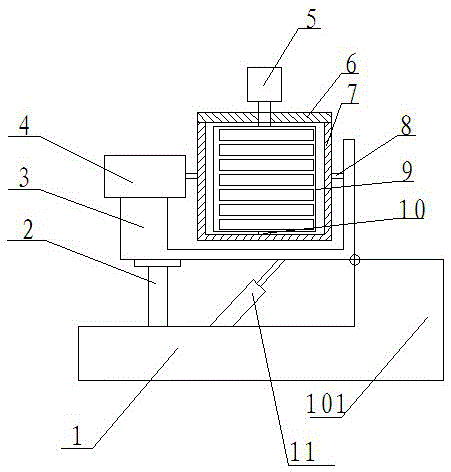

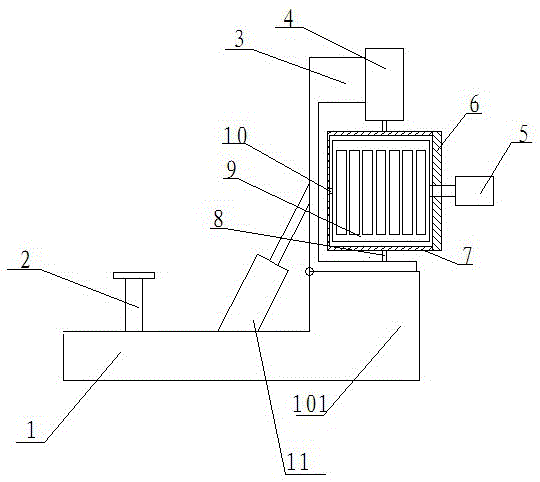

[0011] As shown in the figure, the specific implementation method is as follows:

[0012] 1. An insulin mixing device with automatic reversing, characterized in that it includes a base 1 provided with a boss 101, a concave turntable 3 and a mixing cylinder, and a support column 2 supporting the bottom of the concave turntable 3 is arranged above the base 1, The edge of the bottom of the concave turntable 3 is connected to the edge of the boss on the base 1 through a rotating shaft, so that after the concave turntable 3 rotates 90° around the rotating shaft, an outer wall of the concave turntable 3 fits on the top of the boss, and is fixed on the base 1 There is a hydraulic cylinder 11 with an extended end connected to the bottom of the concave turntable 3. The extended end of the hydraulic cylinder 11 controls and pushes the concave turntable 3 to rotate 90°, and then supports it on the boss. One end of the concave turntable 3 is equipped with a motor I4. The mixing cylinder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com