Patents

Literature

50 results about "Via rectum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

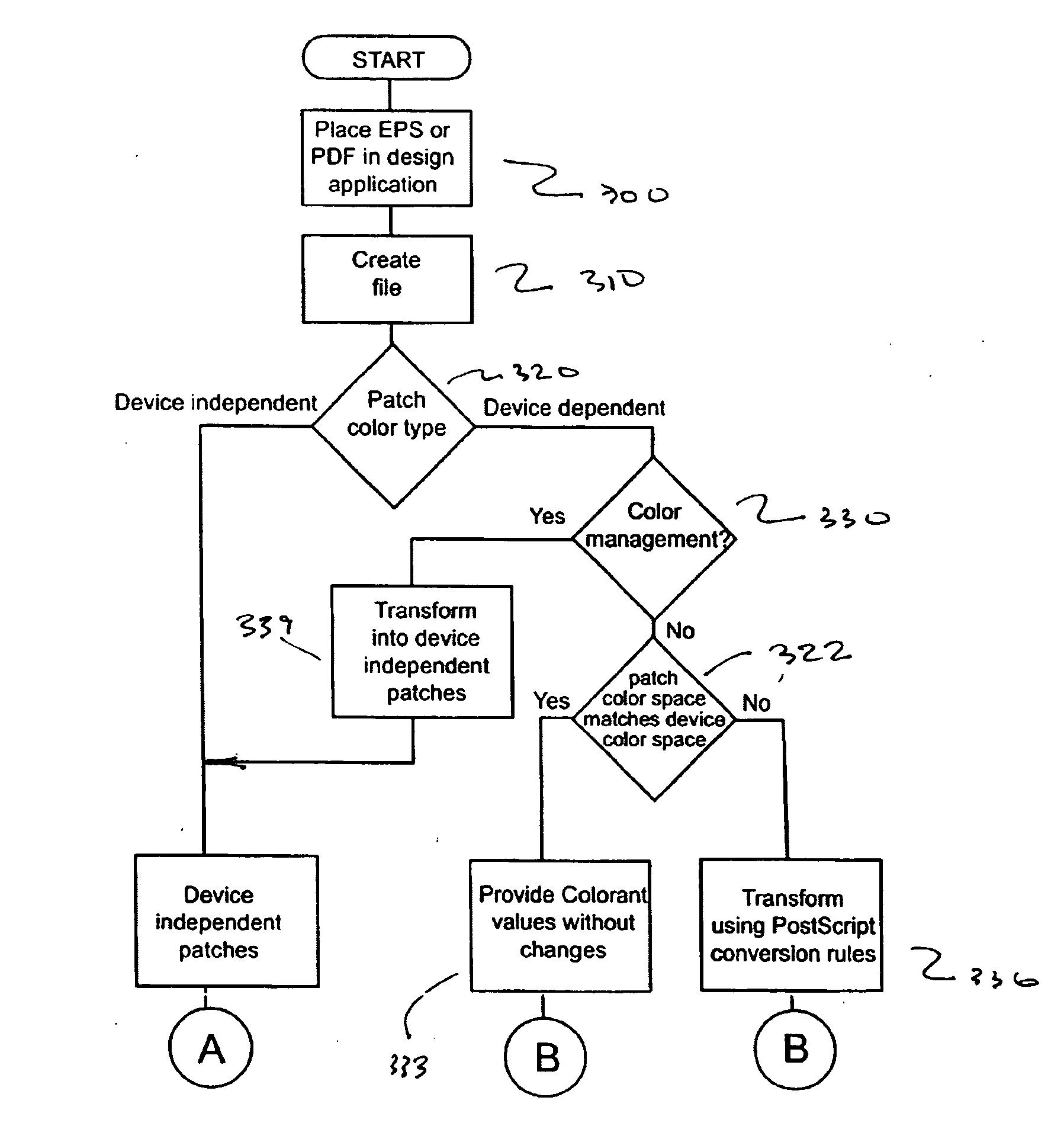

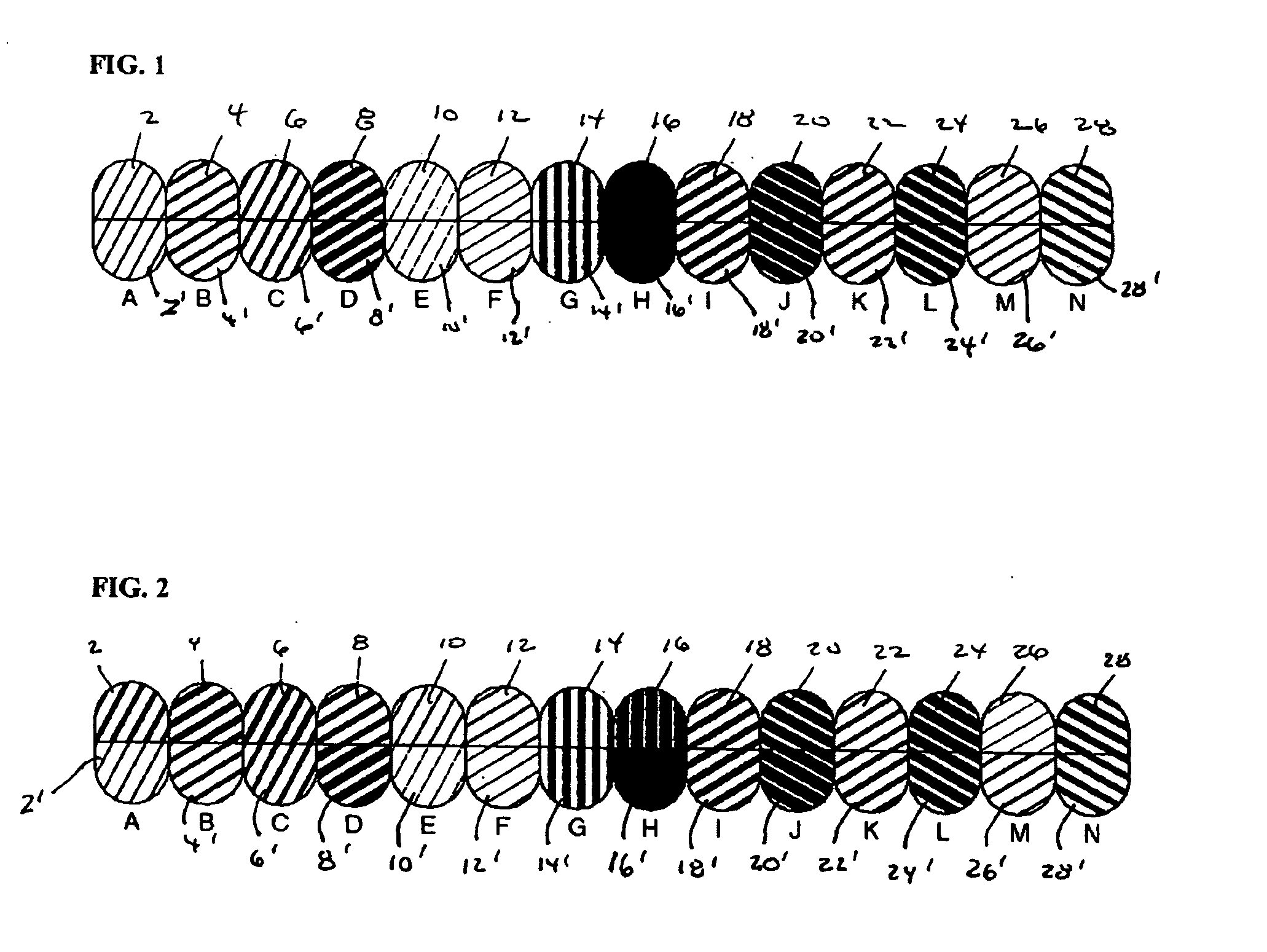

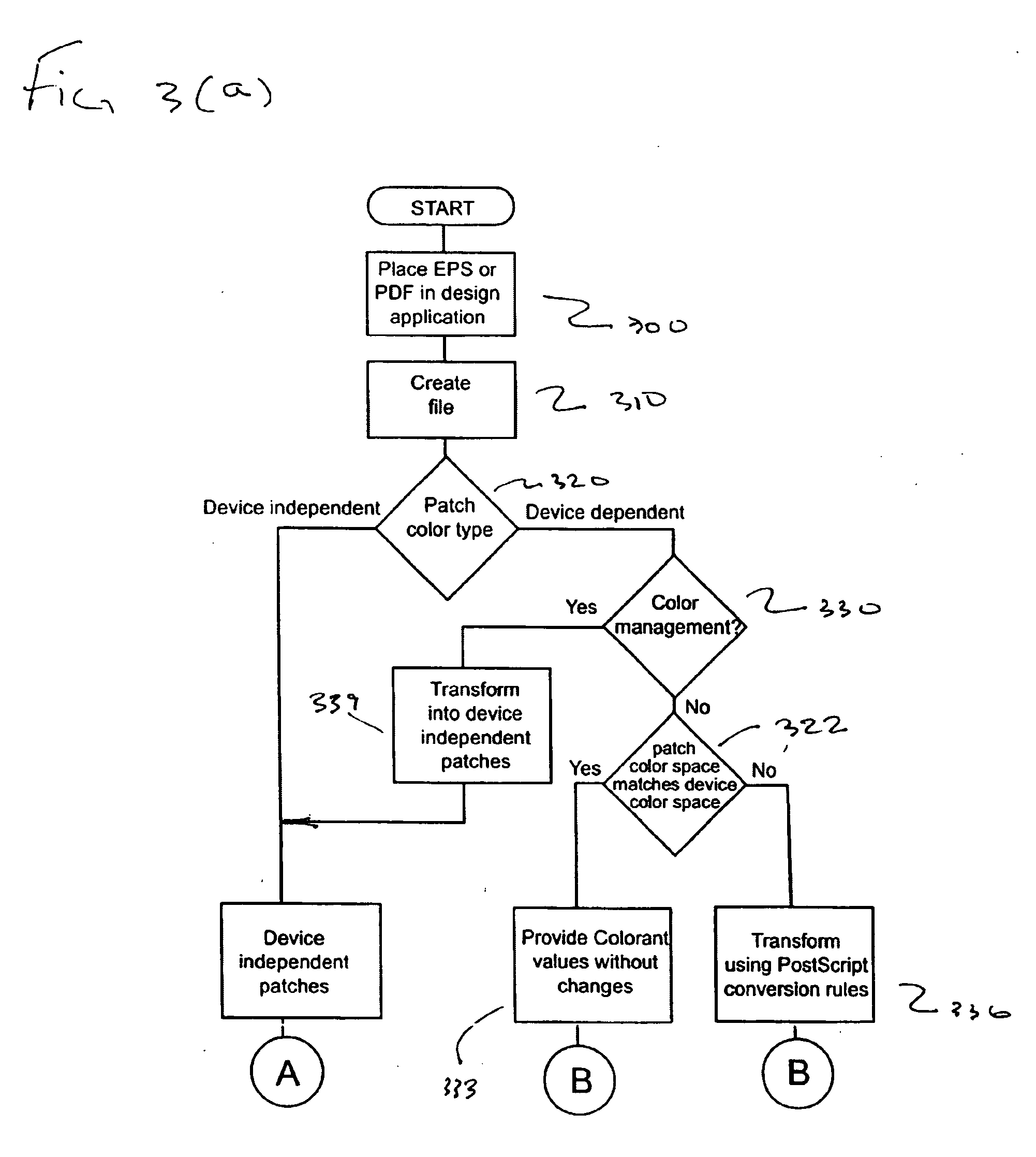

Method for confirming correct selection of an input profile for a color printer

InactiveUS20050275854A1Rapid and accurate visual checkDigitally marking record carriersVisual presentation using printersPattern recognitionVia rectum

Owner:GLOBAL GRAPHICS SOFTWARE

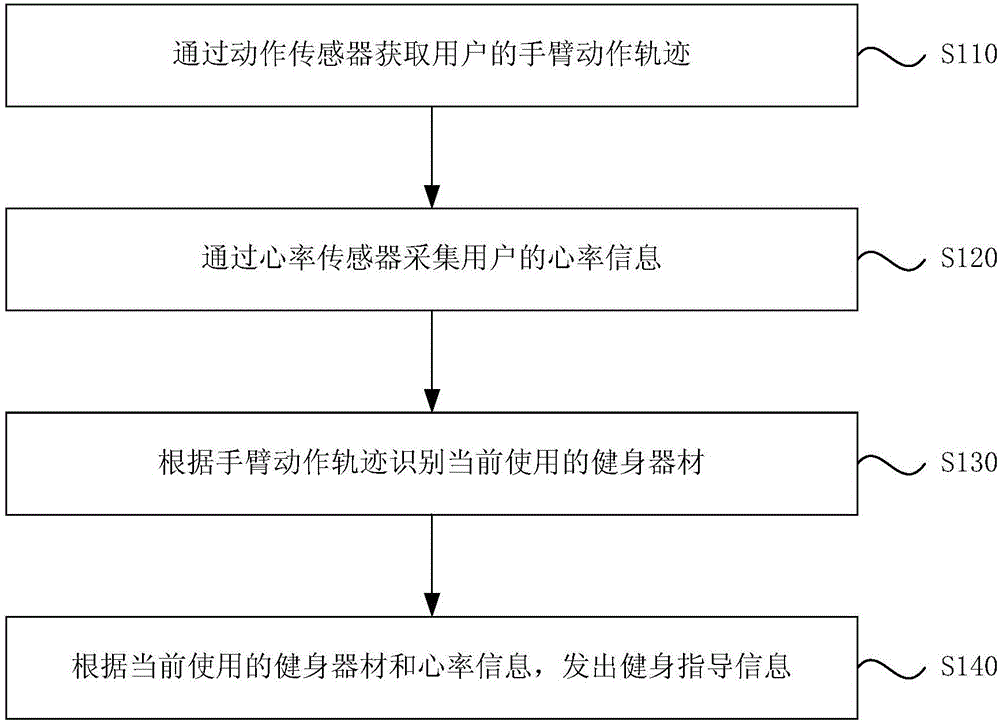

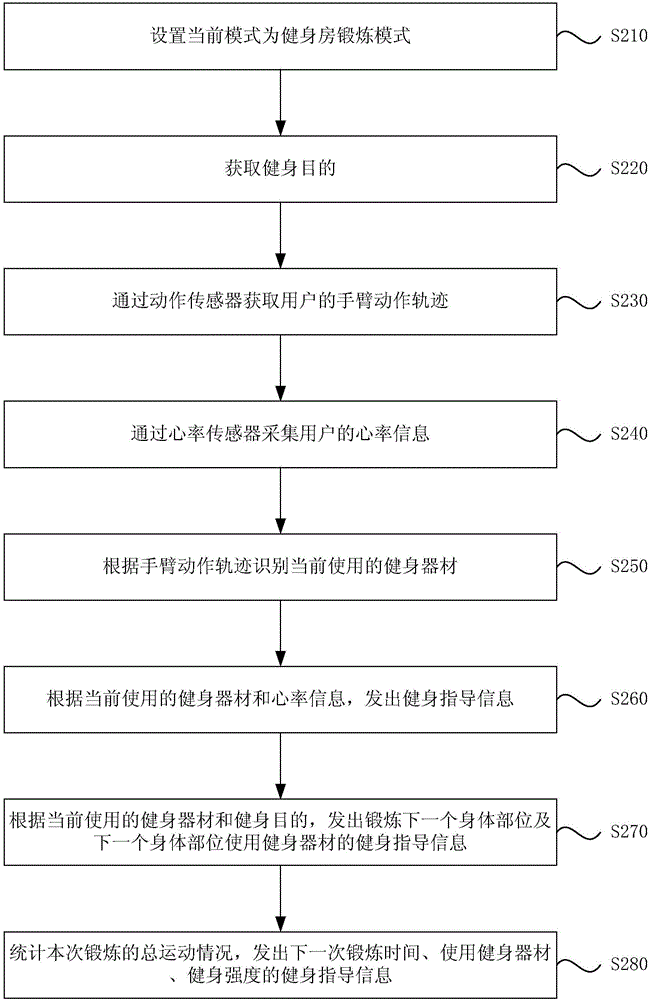

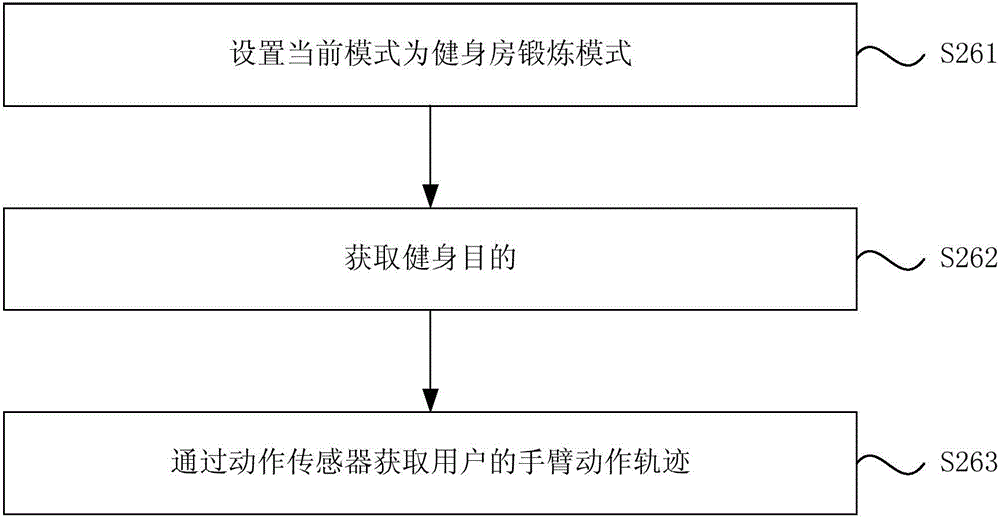

Body-building guide method and device based on intelligent wearable device

The embodiments of the invention disclose a body-building guide method and device based on an intelligent wearable device. The body-building guide method based on the intelligent wearable device comprises the following steps: acquiring an arm motion track of a user by virtue of a motion sensor; collecting heart rate information of the user by virtue of a heart rate sensor; identifying the currently used body-building equipment according to the arm motion track; and sending out body-building guide information according to the currently used body-building equipment and the heart rate information. According to the method, the body-building equipment currently used by the user is identified according to the arm motion track of the user, and scientific body-building guide information is sent to the user according to the currently used body-building equipment and the current heart rate information of the user, thereby guiding the user to use the body-building equipment according to a correct method and reasonably use the body-building equipment to do physical exercises.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

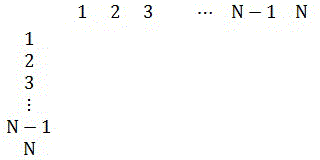

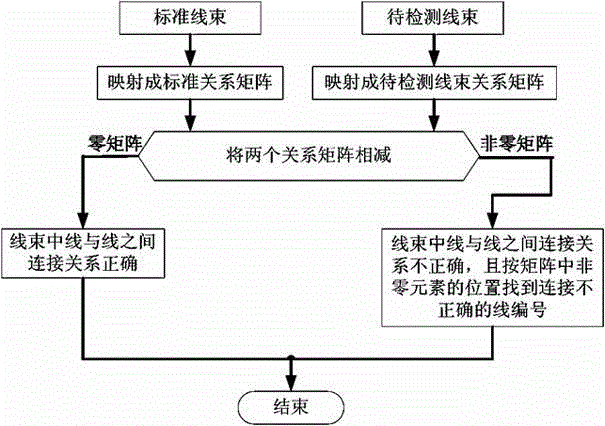

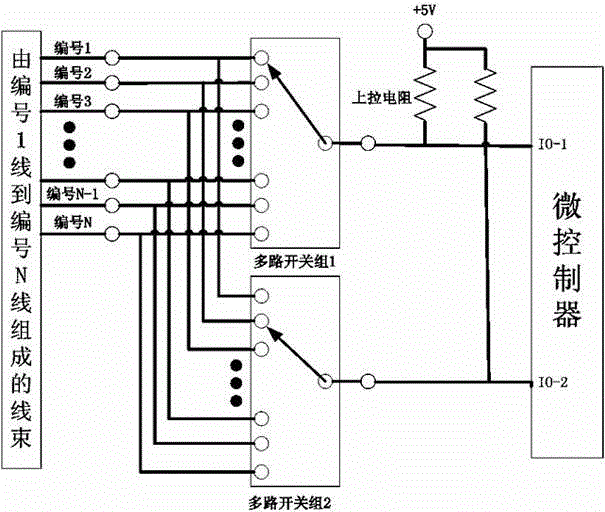

Wire harness automatic detection method based on relation matrix

InactiveCN104931843AQuickly detect connection errorsThe detection process is fastElectrical testingJet aeroplaneVia rectum

Owner:ZHEJIANG WANLI UNIV

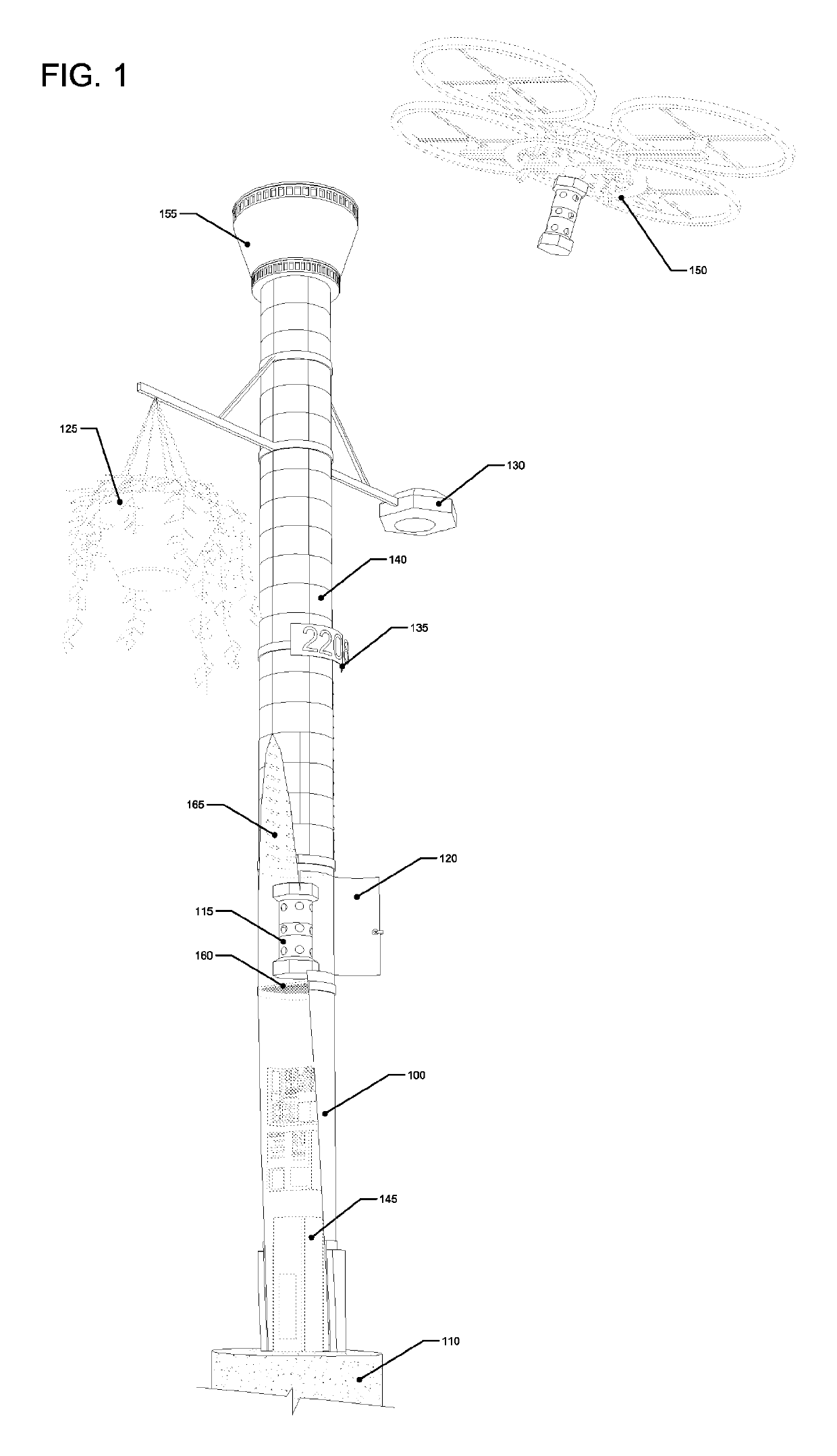

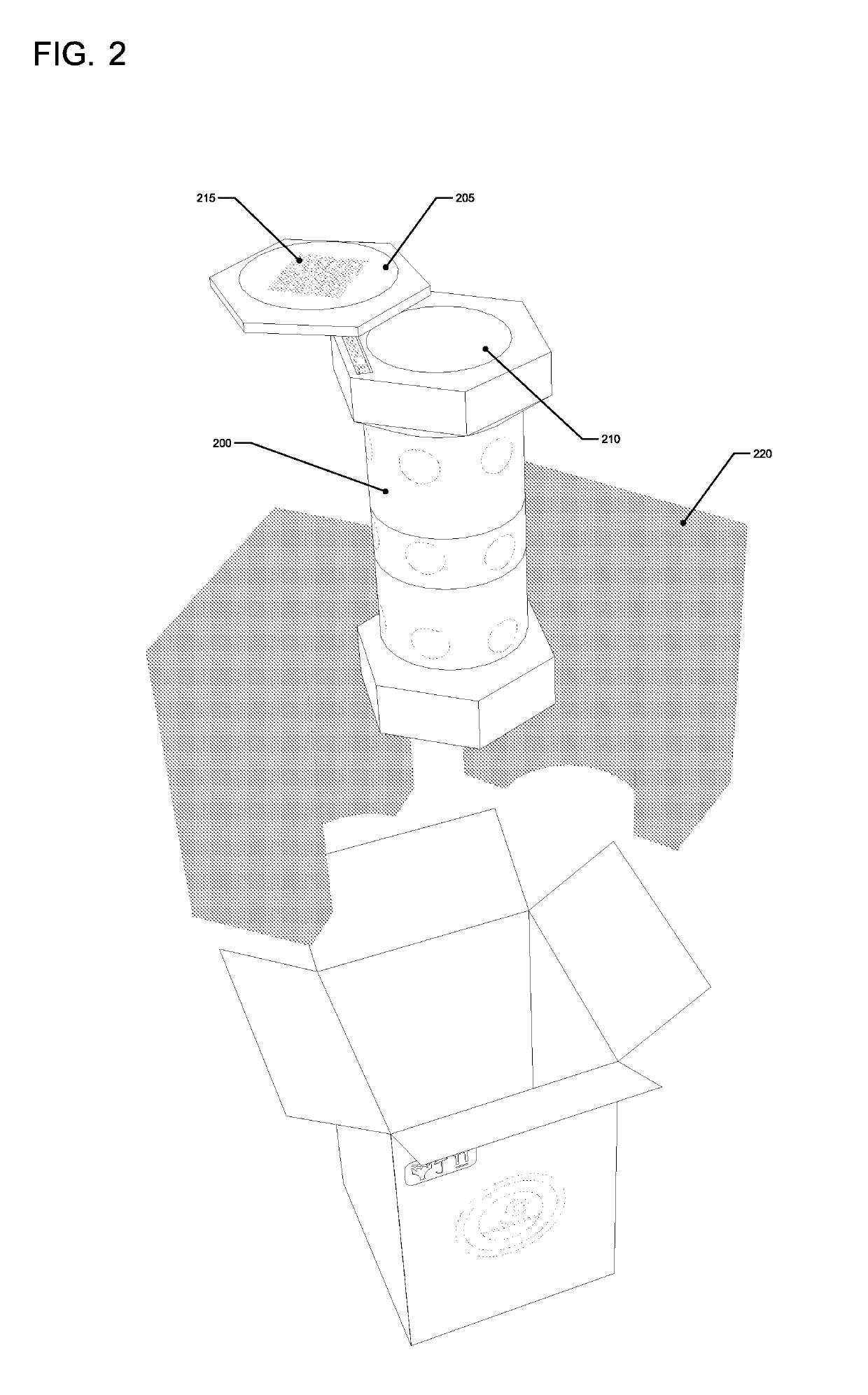

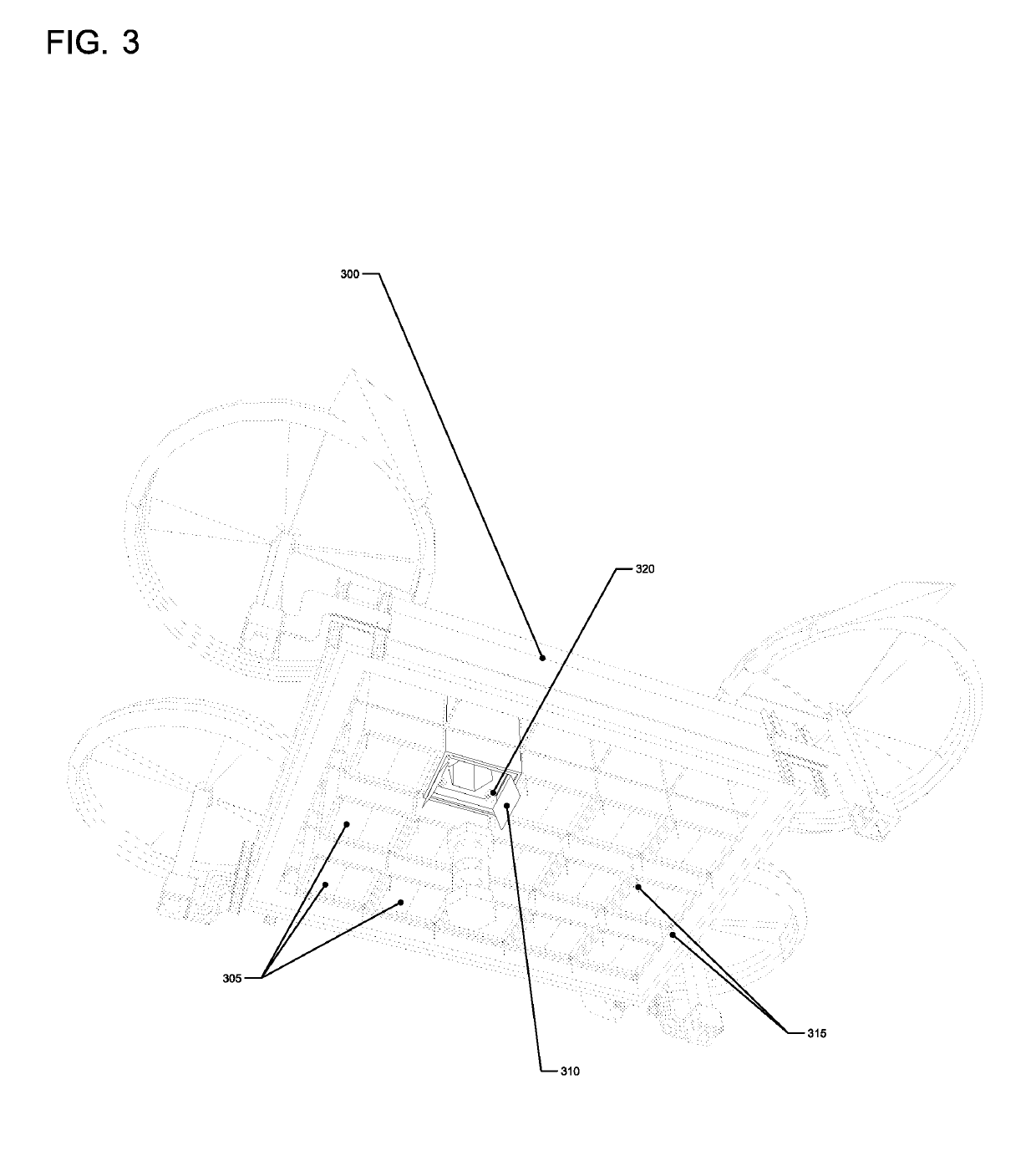

Safe Mail Delivery by Unmanned Autonomous Vehicles

ActiveUS20190125116A1Increase speedKeep distanceConveyorsUnmanned aerial vehiclesHuman exposureVia rectum

Operation of Unmanned Autonomous Vehicles (UAVs) around human population requires the utmost level of safety. Trackpath pre-computed navigation paths and Free flight corridor protection systems reduce the possibility of injuring humans during flight, but at the point of delivery the drone must, by necessity, come down to level of and near humans. This invention teaches the system and method of a personal household mail system that minimizes human exposure to the delivery UAV, provides a method of verifying that the addressee is correct, and optionally secures the mail until it is picked up by the designated recipient.

Owner:BIRKET IP HLDG INC

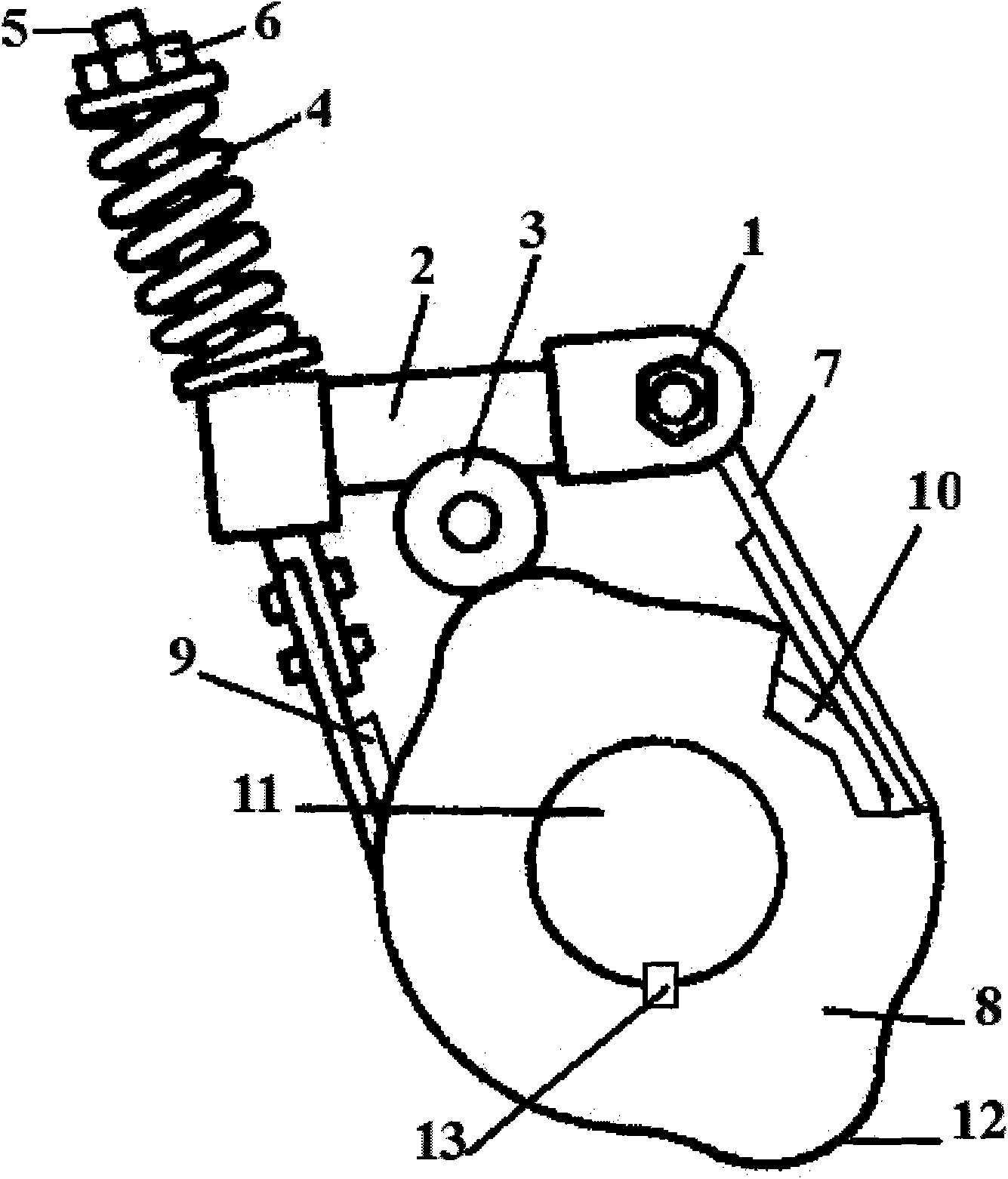

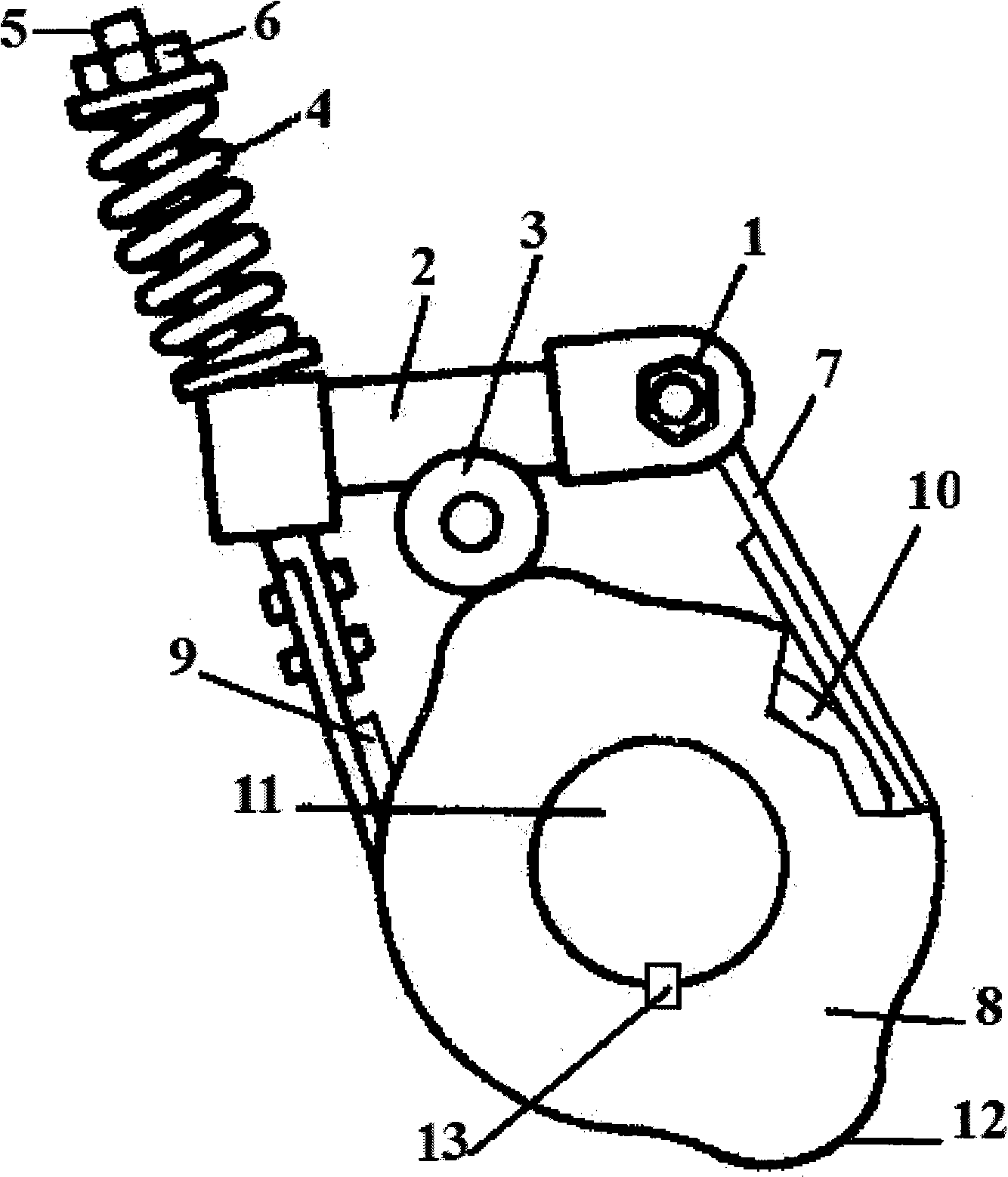

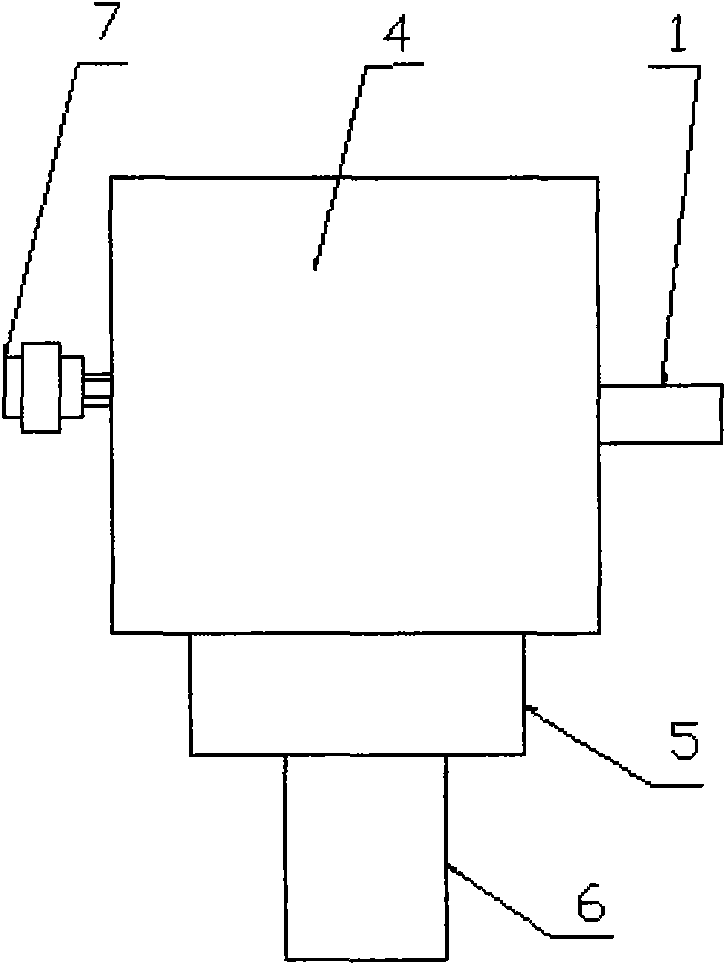

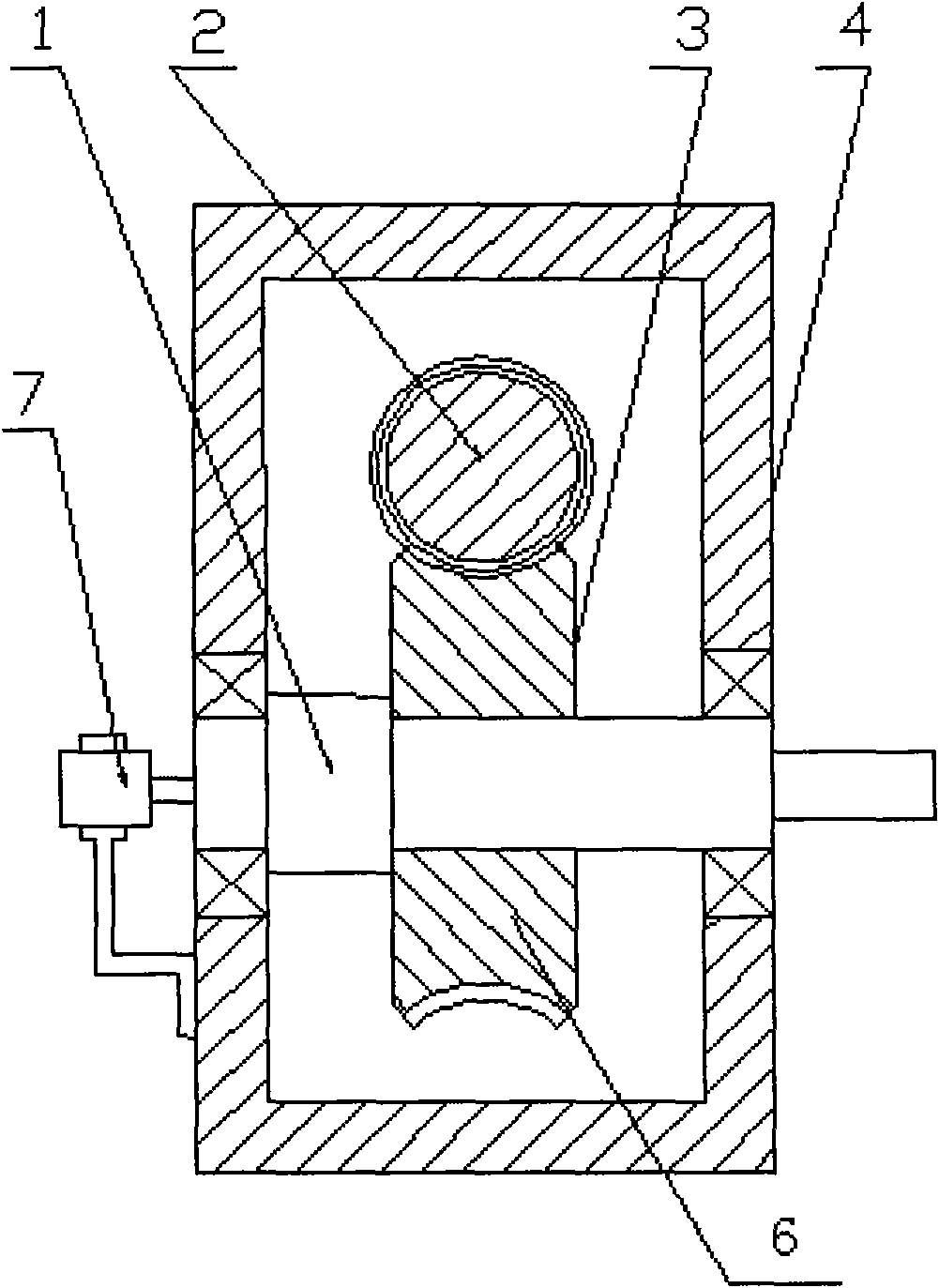

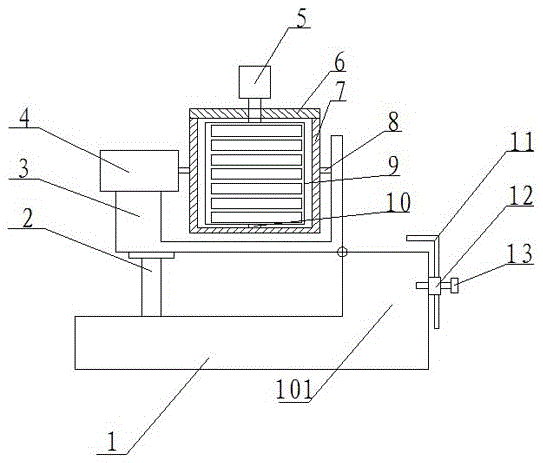

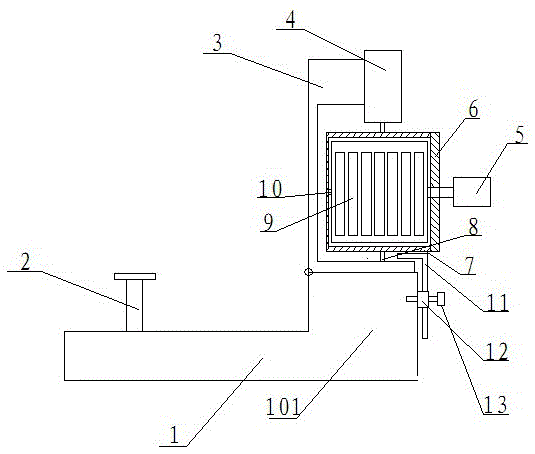

Novel brake mechanism of rigid clutch press

The invention discloses a novel brake mechanism of a rigid clutch press. From inside to outside, a brake wheel and a cam are sequentially arranged and fixed on the upper surface of a crankshaft by a bolt in a way that the positions of protruding arcs correspond to the positions of upper and lower dead points of the crankshaft. A lever is fixedly arranged on the upper surface of a machine body by a pin shaft in a way that the lever is ensured to flexibly rotate about the pin shaft. A roller is fixedly arranged at a proper position on the middle part of the lever by an accurate method. A friction belt is riveted on the upper surface of a brake belt by a rivet. One end of the brake belt is hinged with the pin shaft, and the other end of the brake belt is fixed with a tensioning pull rod by a proper method. The tensioning pull rod passes through a through hole on a lever body, and is sleeved with a spring which is properly pressed by a nut.

Owner:钱慧君

Processing device and processing method of characteristic data of button-pushing behavior

ActiveCN102831435AImprove behaviorLife scienceCharacter and pattern recognitionVia rectumCognition.knowledge

The invention discloses a processing device and a processing method of characteristic data of button pushing behaviors. The processing device comprises a button-pushing behavior characteristic data obtaining module, a button-pushing behavior characteristic data converting module and an awareness cognition function evaluating module, wherein the button-pushing behavior characteristic data obtaining module is used for obtaining the characteristic data of the button-pushing behaviors; the button-pushing behavior characteristic data converting module is used for converting the characteristic data of the button-pushing behaviors into awareness cognition function data; and the awareness cognition function evaluating module is used for comparing the awareness cognition function data with awareness cognition function evaluation information so as to obtain the result of an awareness cognition function. The invention aims at finding the problem that the awareness cognition function is weakened as early as possible, so that correct methods can be adopted in time to enhance the awareness cognition function.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

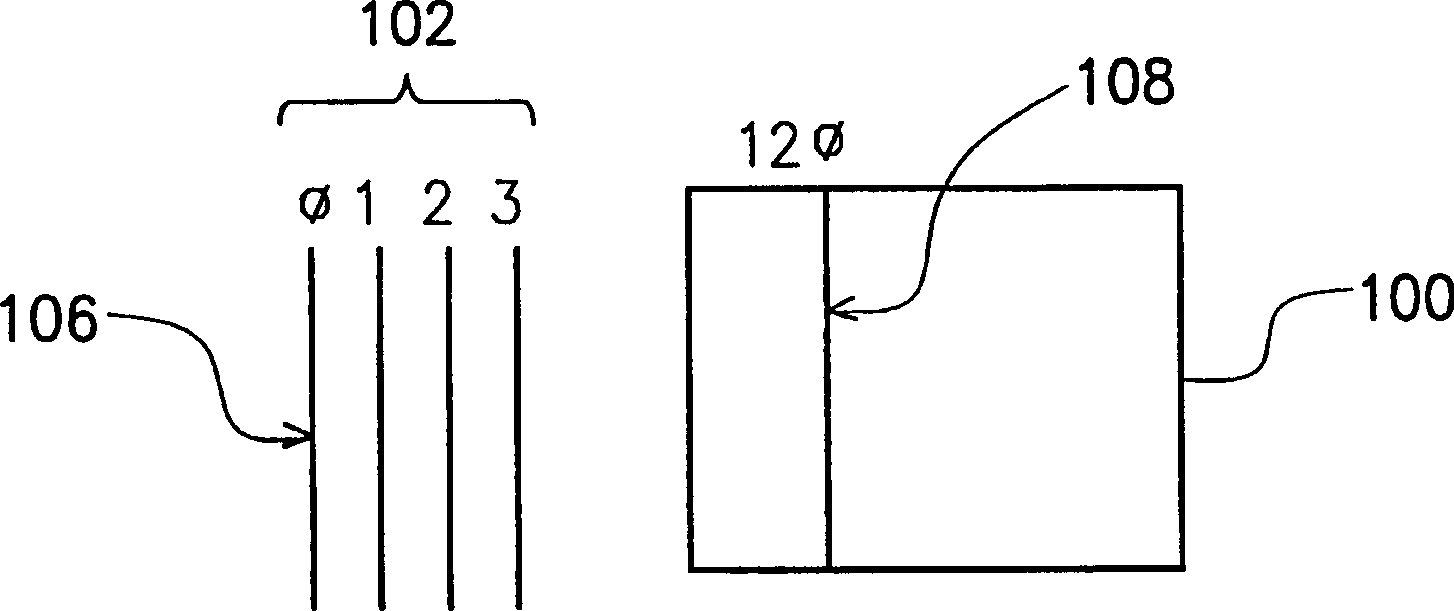

Analysis method of repair state of redundant bit in DRAM

InactiveCN1404140AReduce processing timeSimple processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingVia rectumRandom access memory

The analysis method of repair state of redundant bit in DRAM to detect whether the redundant bit to be repaired correctly is to irradiate the chip with one concentrated light beam and then to observe the physical bit image. When the beam is aims at the defected array position, two semi-circuit bright areas will be displayed in the screen. When the beam is aimed at the redundant bit for repairing the damaged array, one bright strip will be displayed in the screen. Based on the position of the bright strip and the two semi-circular bright areas, whether the repair aim is reached correctely may be detected.

Owner:UNITED MICROELECTRONICS CORP

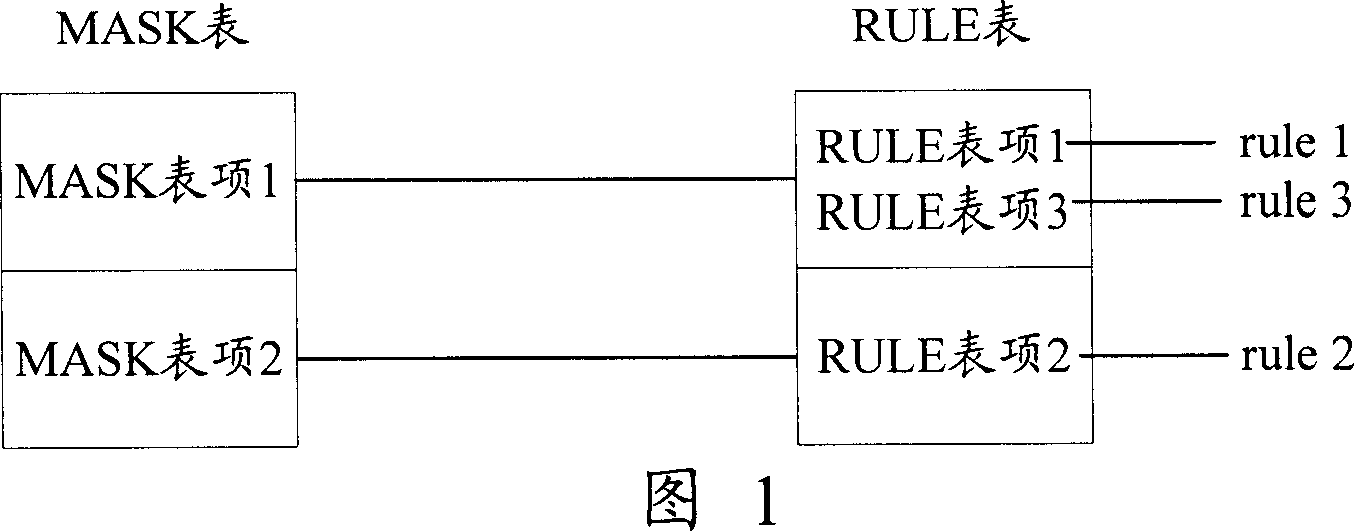

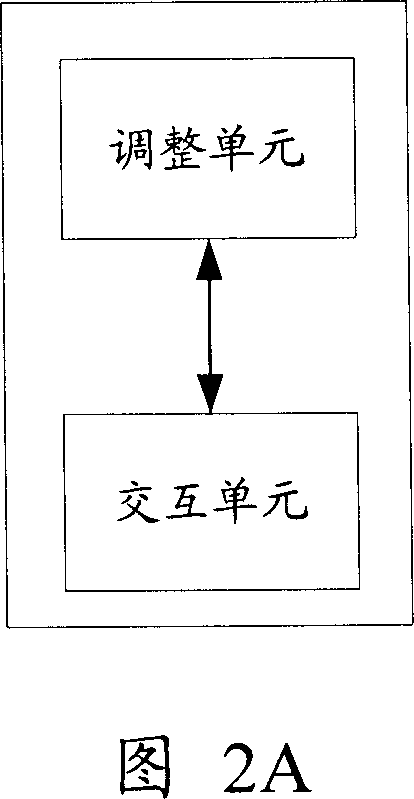

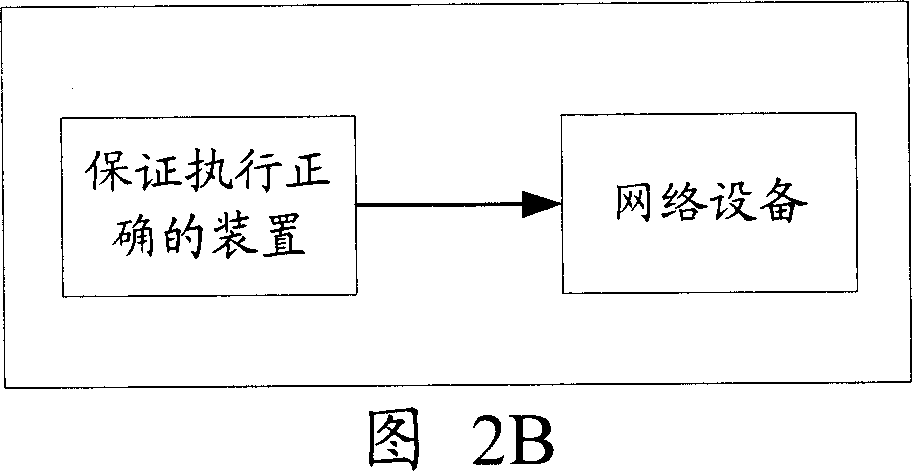

Method, device and system for assuring correct execution

ActiveCN1933487ACorrect business processEnsure correct executionData switching networksComputer hardwareVia rectum

Owner:NEW H3C TECH CO LTD

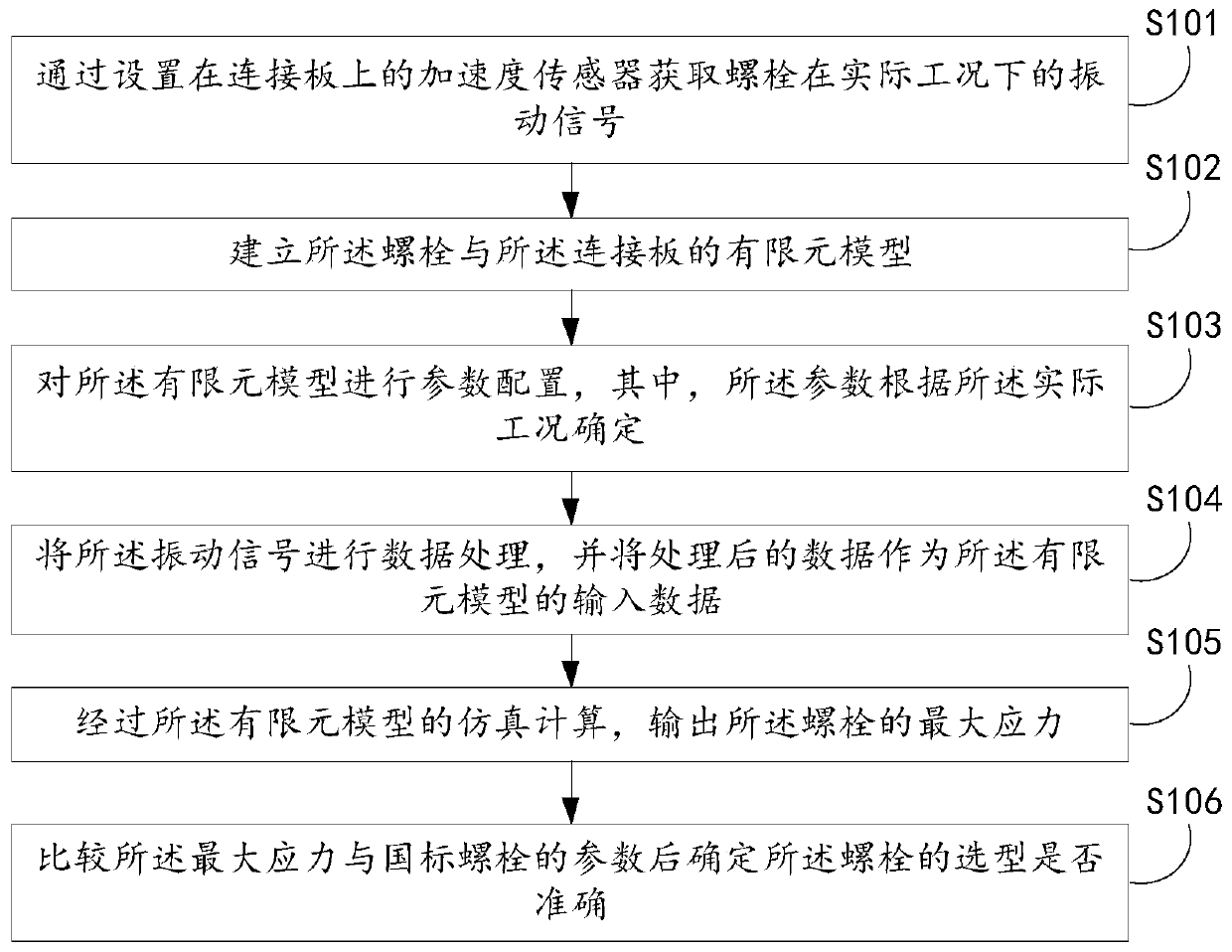

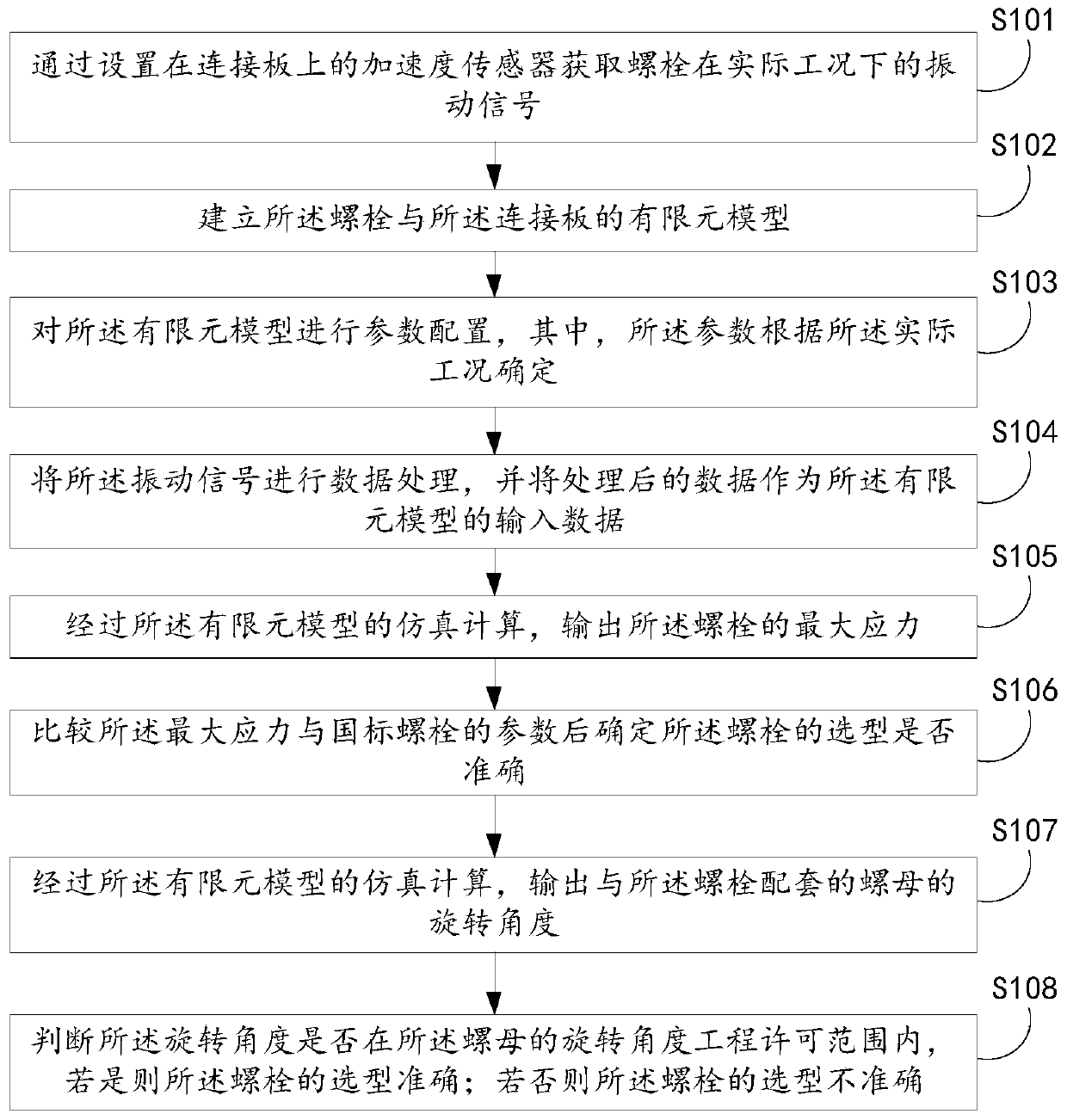

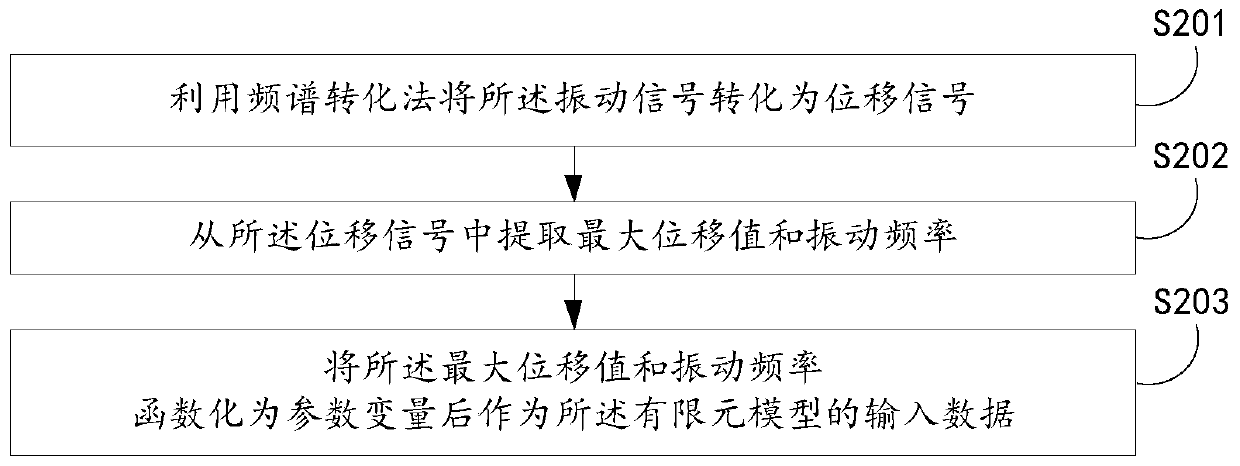

Method for determining whether bolt type selection is correct

PendingCN110610063AAvoid uncertaintyShort cycleSpecial data processing applicationsElement modelVia rectum

The embodiment of the invention discloses a method for determining whether the bolt type selection is correct or not. The method comprises the steps of obtaining a vibration signal of a bolt under theactual working condition through an acceleration sensor arranged on a connecting plate; establishing a finite element model of the bolt and the connecting plate; carrying out parameter configurationon the finite element model, wherein the parameters are determined according to the actual working conditions; performing data processing on the vibration signal, and taking the processed data as theinput data of the finite element model; outputting the maximum stress of the bolt through the simulation calculation of the finite element model; and comparing the maximum stress with the parameters of the bolt of a national standard to determine whether the type selection of the bolt is accurate or not. According to the technical scheme, the situation that the fault is fed back to the engineers only after the bolt goes wrong, so that the bolt type selection period is shortened, and the efficiency is improved.

Owner:SHANDONG TAIKAI HIGH VOLTAGE SWITCH

Method for measuring interface pressure based on cold contraction type cable intermediate joint

InactiveCN108931325AEffective direct measurementOptimize layoutForce measurement using piezo-resistive materialsVia rectumData acquisition

The invention relates to the technical field of measurement for the installation contact interface pressure between a cable body and an intermediate joint, and more specifically relates to a method for measuring the interface pressure based on a cold contraction type cable intermediate joint. The method comprises the steps of selecting a thin film piezoresistive sensor and a lead; determining themeasurement position of the interface pressure, and fixing the piezoresistive sensor so as to enable the piezoresistive sensor to cling to the measurement position; arranging the lead along an axis direction of the cable; installing the cold contraction type cable intermediate joint, and enabling the piezoresistive sensor to be pressed against the contact interface of the cable body and the cold contraction type cable intermediate joint; and connecting the lead to a data acquisition system, and monitoring the interface pressure in real time. According to the invention, the cold contraction type cable intermediate joint is sleeved after the piezoresistive sensor is arranged, the installation of the intermediate joint is completed according to a correct method, the piezoresistive sensor is pressed against the installation interface of the cable body and the cold contraction type cable intermediate joint, and the lead is connected to the data acquisition system, thereby being capable of realizing long-term and effective direct measurement for the interface pressure, and being simple, fast and accurate in measurement.

Owner:GUANGDONG POWER GRID CO LTD +1

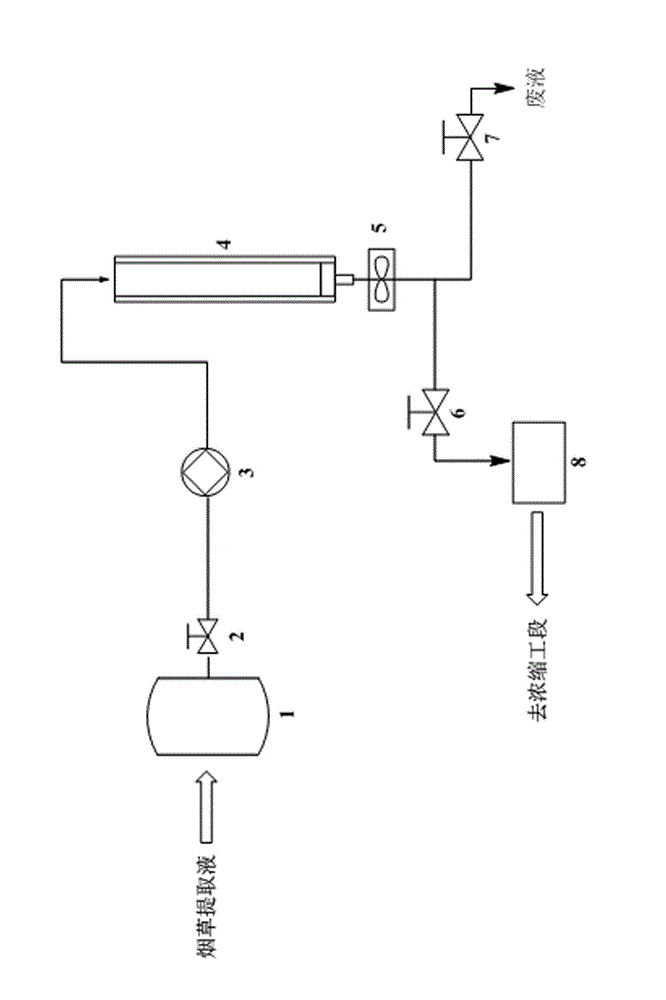

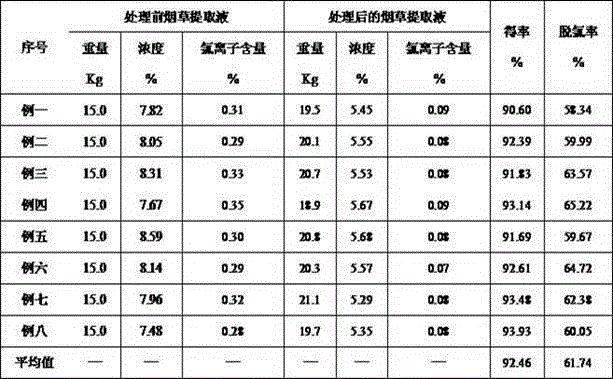

Method for removing chloride ions from paper-making reconstituted tobaccos

InactiveCN103549642AReduce Chloride ContentImprove inner qualityTobacco preparationTobacco treatmentIon contentOrganic acid

A method for removing chloride ions from paper-making reconstituted tobaccos is used for treating a tobacco extract with anion exchange resin to remove the chloride ions. The method comprises the steps of conveying the tobacco extract at a concentration (a solid content) of 4-10% into a storage tank, conveying into an anion exchange column when the temperature is controlled at 40-45 DEG C, allowing the tobacco extract to completely pass through the anion exchange resin within 5-7min, adding clear water into the storage tank for rinsing, after the clear water passes through the ion exchange column completely, merging the clear water and liquid obtained in the previous step to form a dechlorinated tobacco extract, adding an appropriate amount of self-prepared composite organic acid to regulate a pH (potential of hydrogen) value of the tobacco extract to be 4.6-4.8, and directly conveying to a refining and concentration working section. The method effectively reduces a chloride ion content in the tobacco extract and ensures a high product yield; the anion exchange resin can be recycled for many times after recovered and activated by a correct method; and the sensory quality of the prepared dechlorinated tobacco extract is not changed obviously.

Owner:HONGTA TOBACCO GRP

Evaluation model for zinc biological effectiveness in foods and establishment method thereof

InactiveCN102676369ABioreactor/fermenter combinationsBiological substance pretreatmentsEvaluation resultHuman intestinal absorption

The invention relates to an evaluation model for zinc biological effectiveness in foods and an establishment method thereof. The model comprises a model structure, cell types and evaluation indexes, wherein the evaluation indexes are the zinc content in Caco-2 cells, cell transported zinc quantity and the zinc content in epithelial cells of internal organs. The model can accurately, efficiently and comprehensively simulate the zinc absorbing and utilizing process in a human body and provides a reasonable and correct method for evaluating the zinc biological effectiveness in the foods; the model structure is similar to a human intestinal absorption structure; the model can evaluate the absorption efficiency of zinc in the foods in an intestinal tract and also can evaluate the utilization efficiency of the zinc in the human body; and evaluation results are close to the actual zinc biological effectiveness.

Owner:HENAN UNIV OF SCI & TECH

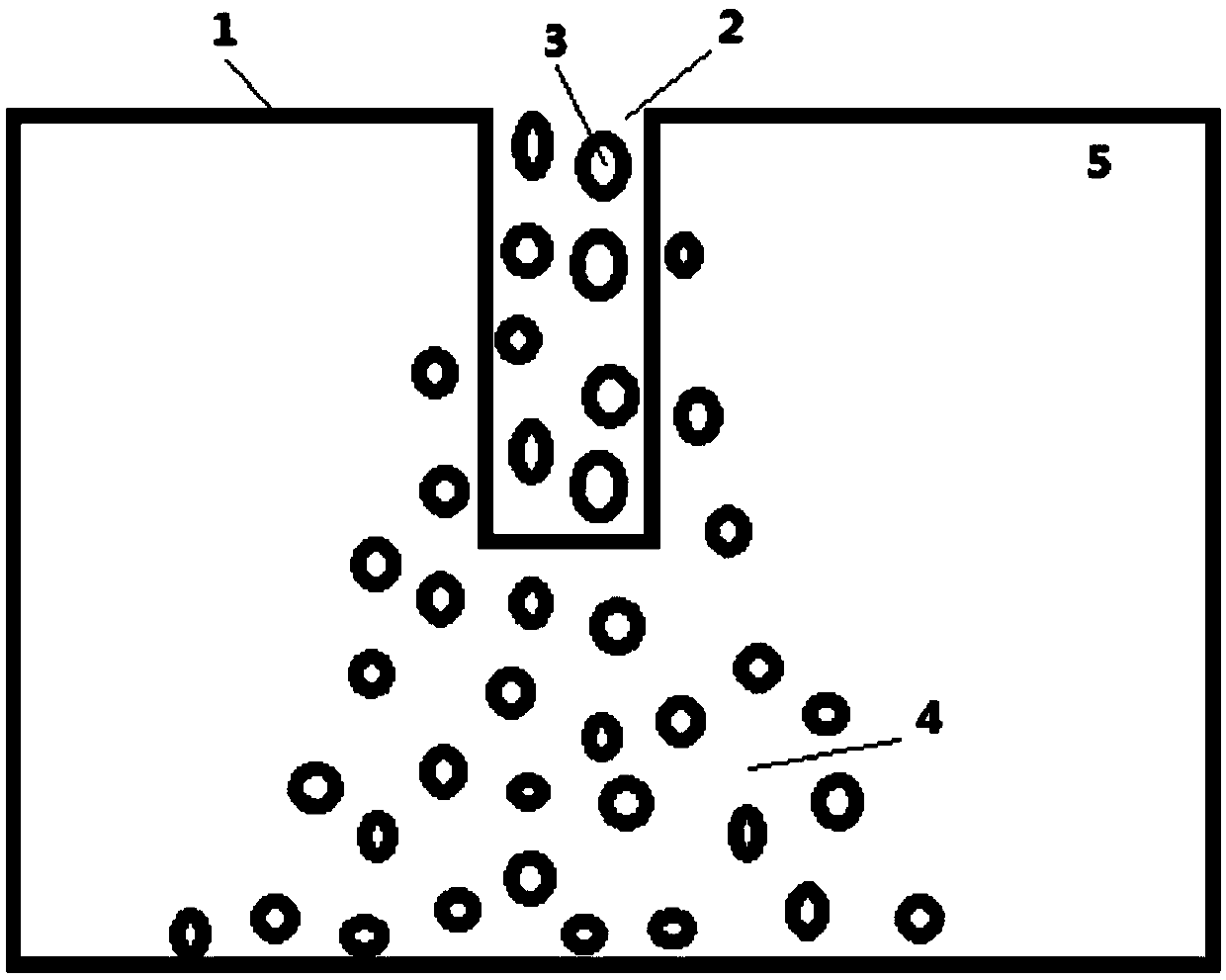

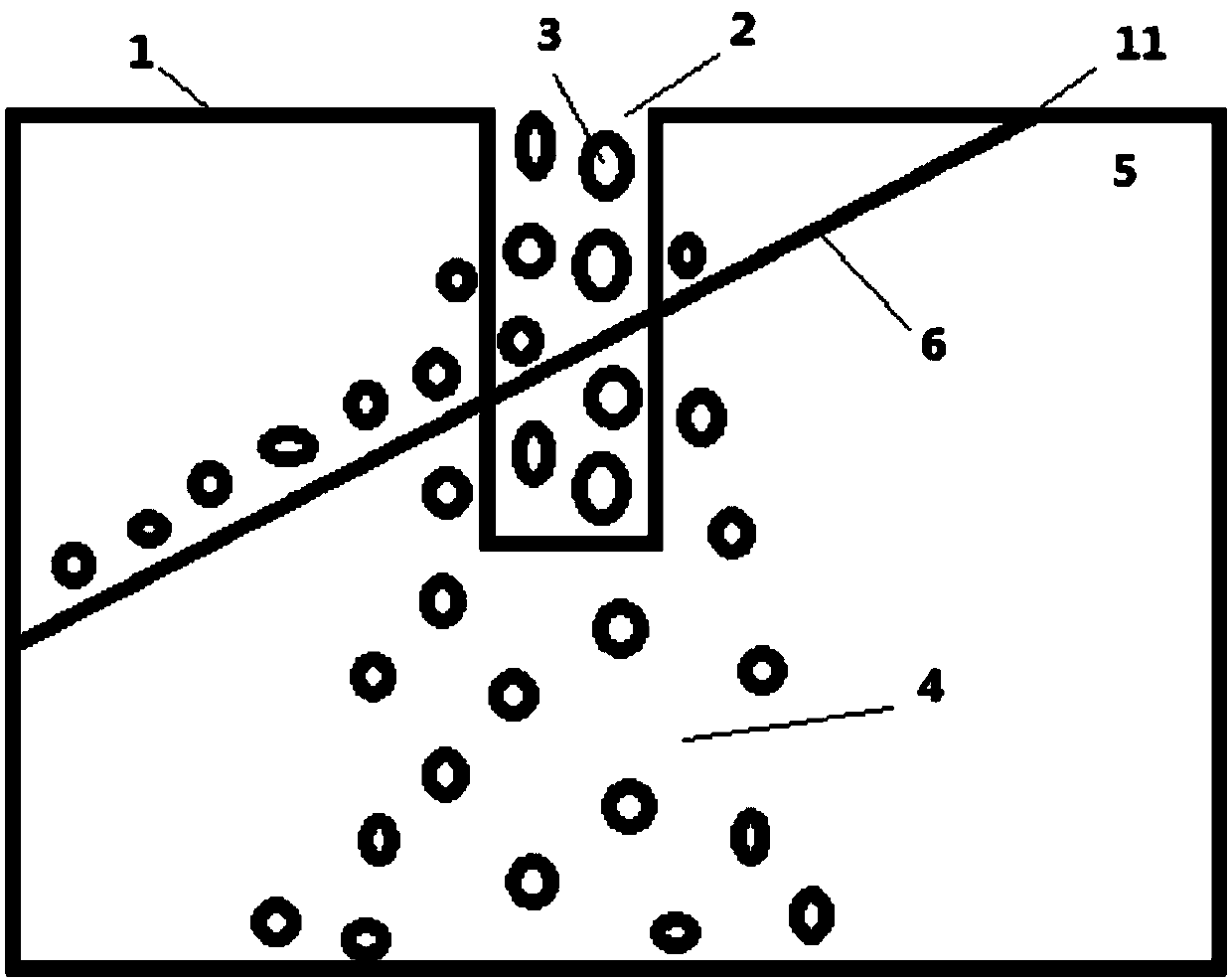

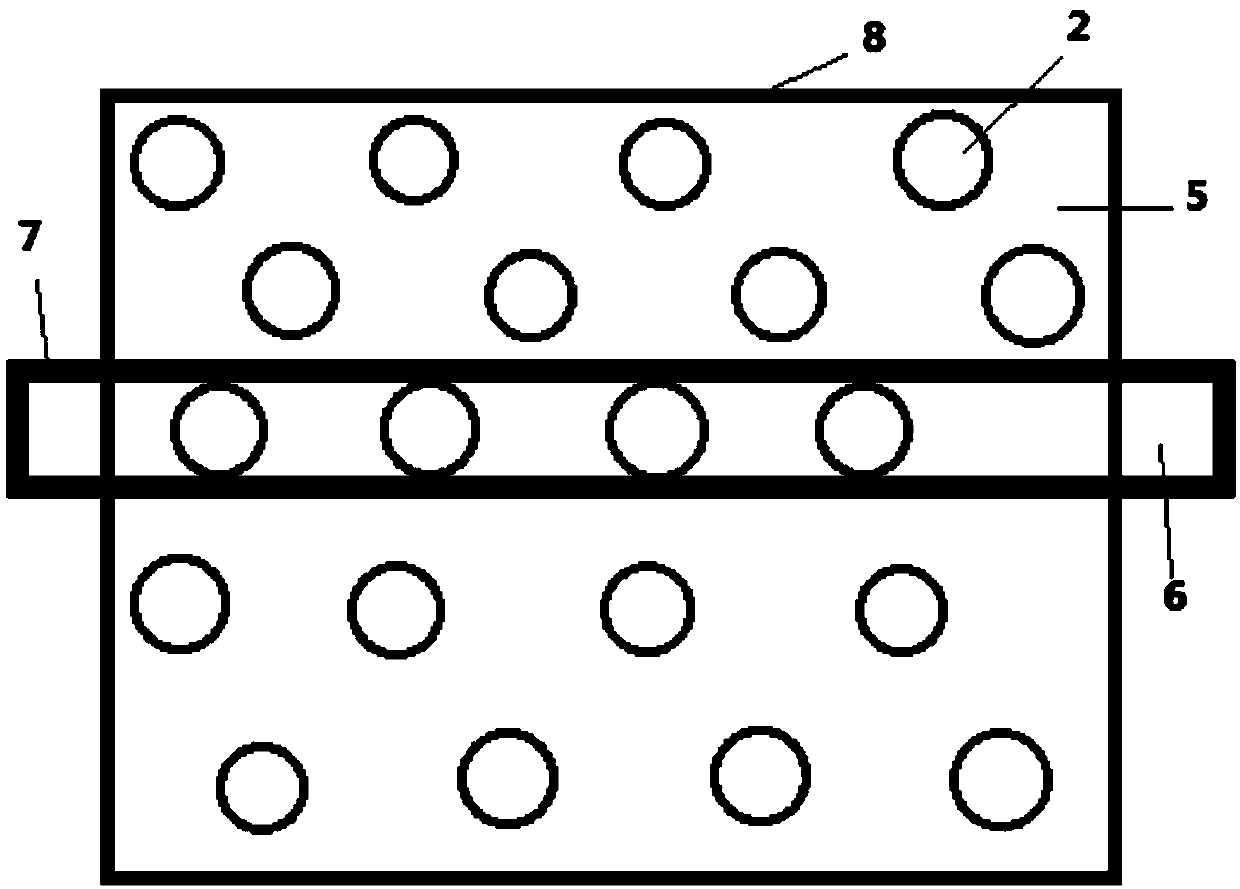

Method for assisting ionic rare earth ore in-situ leaching technology through three-dimensional remote sensing technology

InactiveCN109593958AImprove mining efficiencyAlleviate the pressure on the ecological environmentProcess efficiency improvement3D modellingVia rectumRare earth

The invention provides a method for assisting an ionic rare earth ore in-situ leaching technology through a three-dimensional remote sensing technology. An unmanned aerial vehicle and the three-dimensional remote sensing technology thereof are adopted for measuring the ionic rare earth ore area work area ground surface, a ground surface three-dimensional remote sensing model is built, the remote sensing interpretation of the ground surface three-dimensional remote sensing model is used for obtaining geological environment information of the position, the plane extension direction, the profileextension condition and the like of the section, according to the remote sensing structure explanation result, the influence of the result on the rare earth ore in-situ leaching technology is analyzed, and the correct method is adopted for responding. For a large-scale profile in the area, commonly, distributed drilling holes need to be away from the profile, and flowing of leaching solutions is reduced; for small-scale profiles, the profile is used for gathering the leaching solution; and the remote sensing technology is adopted for assisting the ionic rare earth ore in-situ leaching production, the recycling rate of the leaching solution can be obviously improved, production cost is saved, investment risks are reduced, and the influence on the environment can be reduced to the maximum degree.

Owner:CENT SOUTH UNIV +1

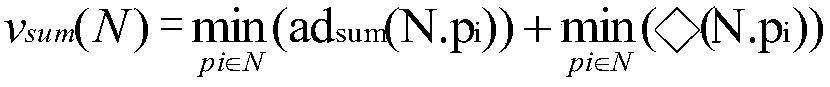

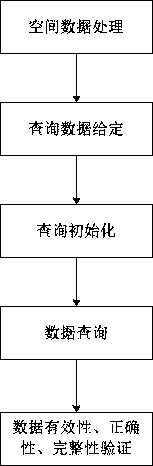

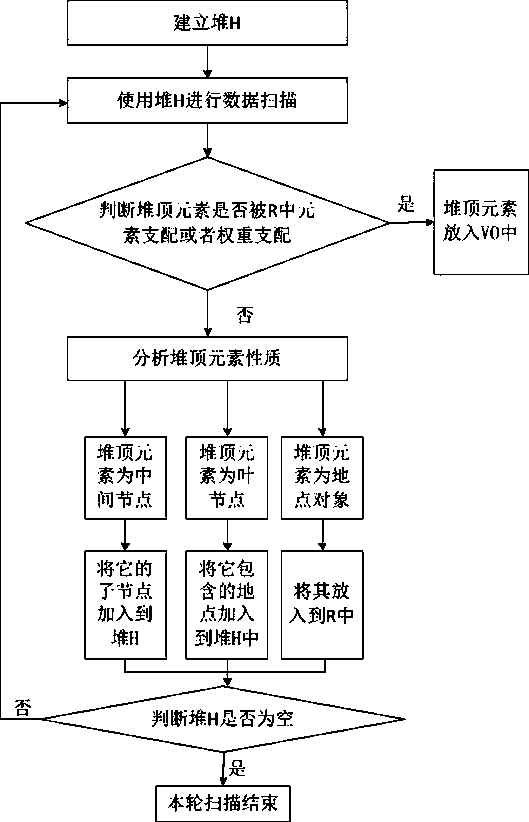

Multi-user decided spatial data query and verification method

InactiveCN105912574ACutting costsAccurate methodSpecial data processing applicationsValidation methodsVia rectum

The invention discloses a multi-user decided spatial data query and verification method comprising a spatial data processing step S1, a query data giving step S2, a query initialization step S3, a data query step S4, and a data verification step S5. The multi-user decided spatial data query and verification method provided by the invention can be applied to a multi-user decided scenario. Users in a group each get a good result according to the location and hobbies thereof. An effective, complete and correct method is provided for multi-user based large-amount spatial data query and verification in a big data environment.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

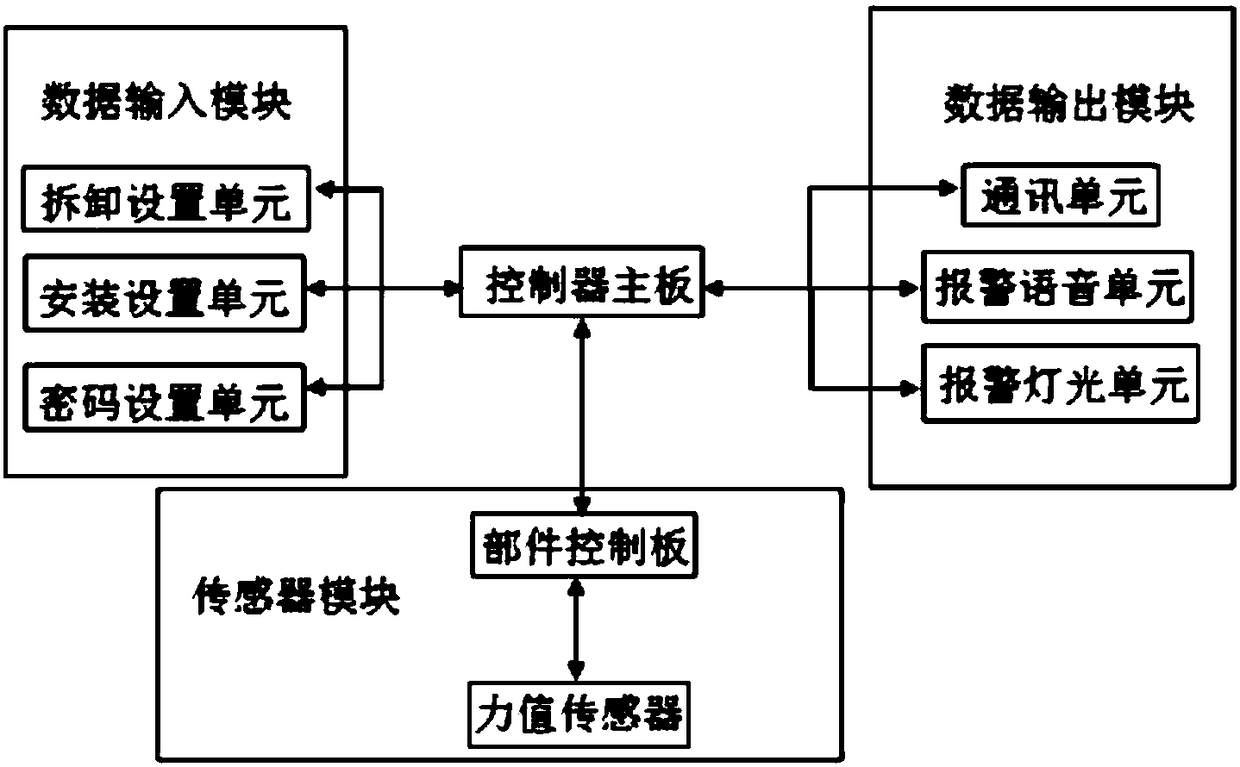

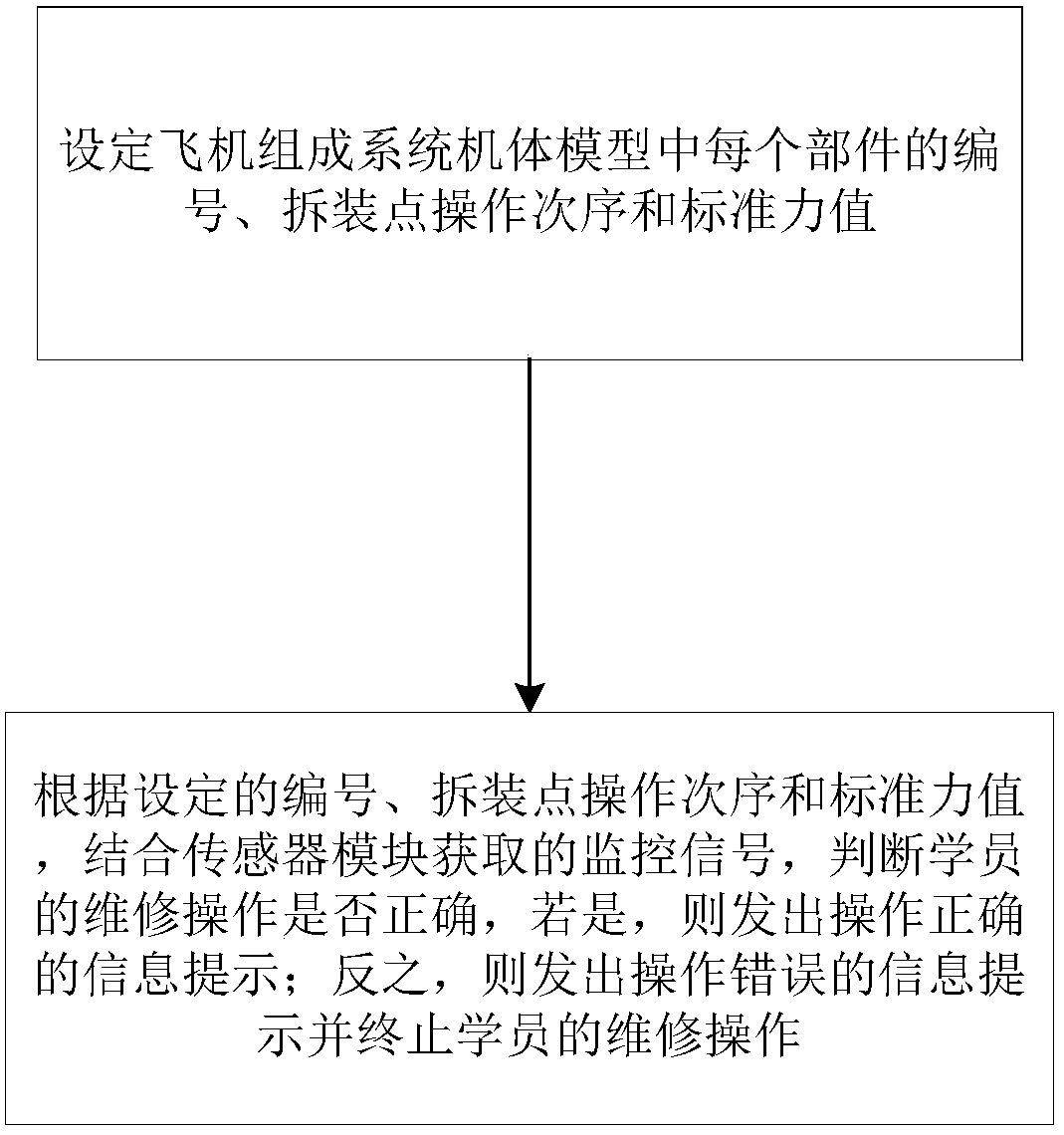

Aircraft composition system maintenance practical training monitoring system and implementation method thereof

ActiveCN108267969AEasy to replaceLow priceCosmonautic condition simulationsSimulator controlVia rectumControl system

The present invention discloses an aircraft composition system maintenance practical training monitoring system and an implementation method thereof. The system comprises an aircraft composition system airframe model, a sensor module and a control system. The method comprises the steps of: setting numbers of each part, operation orders of dismounting points and a standard force value in the aircraft composition system airframe model; and combining monitoring signals obtained by a sensor module to determine whether students' maintenance operation is correct or not according to the set numbers,the operation orders of the dismounting points and the standard force value. The manufacturing of the aircraft composition system airframe model or a purchased device is low in cost; parts of the aircraft composition system airframe model are easy to replace and low in cost; and moreover, the aircraft composition system maintenance practical training monitoring system and the implementation methodthereof can perform real-time monitoring of each-step operation of the students, can timely terminate the students' faulty maintenance operation, can assist the students in development of good work habits and grasp of a correct method and can improve the teaching effect. The aircraft composition system maintenance practical training monitoring system and the implementation method thereof can be widely applied to the technical field of civil aviation maintenance practical teaching.

Owner:GUANGZHOU CIVIL AVIATION COLLEGE

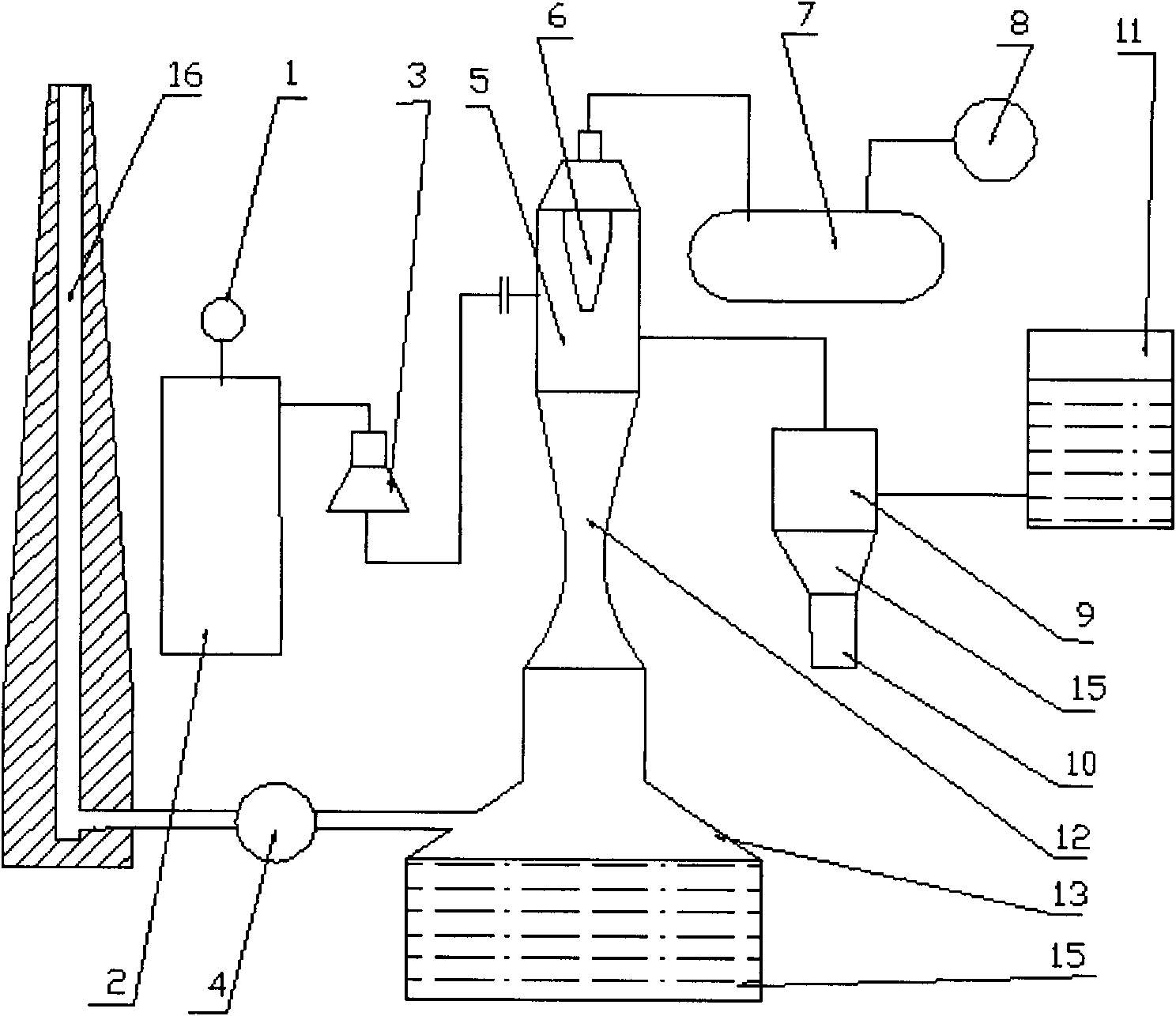

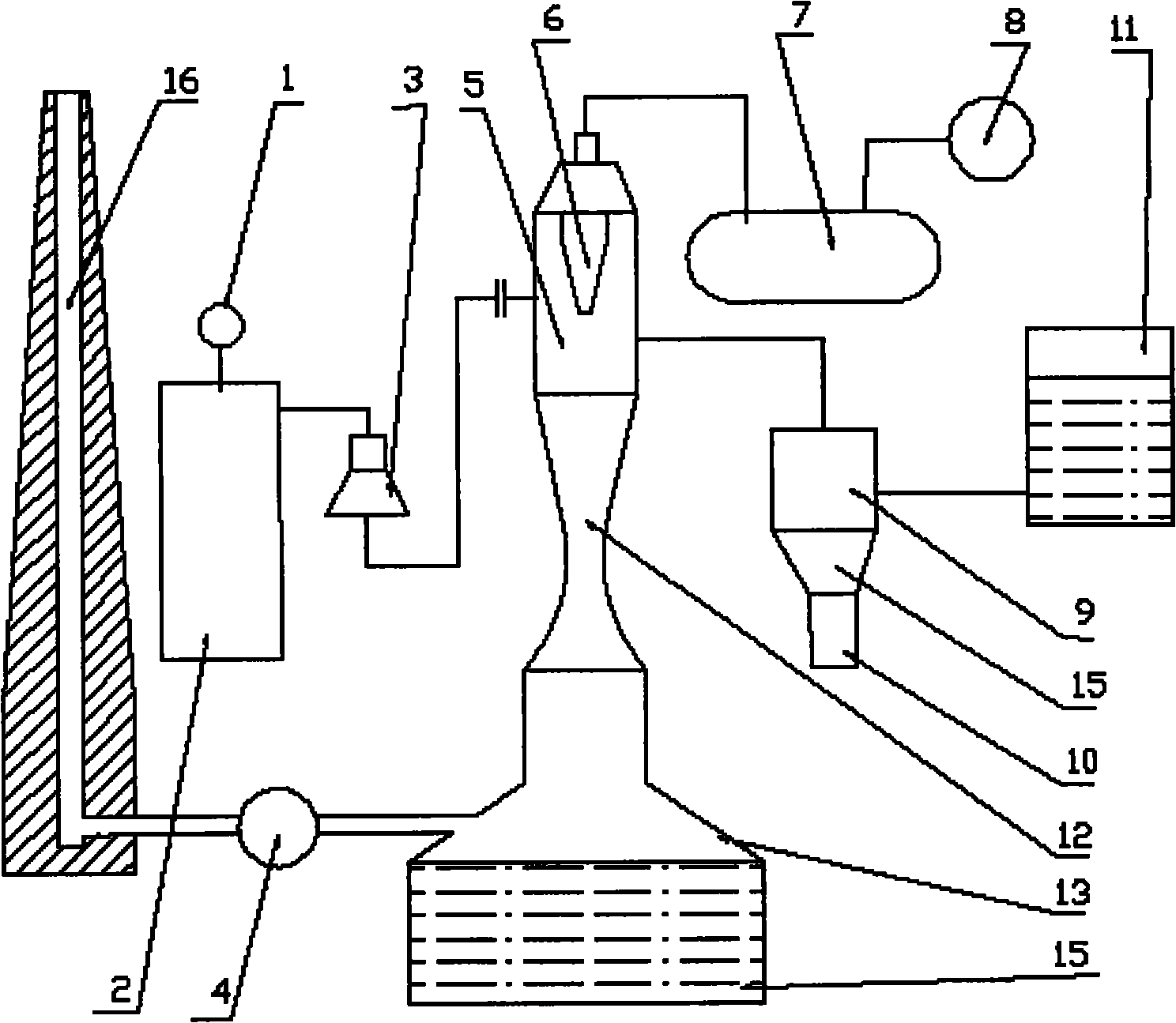

Novel boiler smoke prevention and dust control device

InactiveCN101988704AImprove purification qualityReduce volumeLighting and heating apparatusDispersed particle separationVia rectumDust control

The invention relates to a novel boiler smoke prevention and dust control device which is characterized in that a designed nozzle, a designed negative pressure chamber and a Venturi tube are rightly arranged in the negative pressure chamber, the lower end of the negative pressure chamber is provided with the Venturi tube; the Venturi tube and a smoke hood are rightly arranged, the smoke hood covers on a circulating pool with a proper method, a centrifugal machine is connected with a smoke tube by using a pipeline with a proper caliber; an inlet of the centrifugal machine is connected with a boiler body by using a pipeline with a proper caliber and an outlet is connected with the negative pressure; a gas storage cylinder is respectively connected with an air compressor and the nozzle by using pipelines with proper calibers; an energy exchanger and an atomizing chamber are arranged and fixed, and an ultrasonic generator and the energy exchanger are arranged and fixed by using a right method; and the atomizing chamber is respectively communicated with a water replenishing tank and the negative pressure chamber by using pipelines with proper calibers.

Owner:朱静

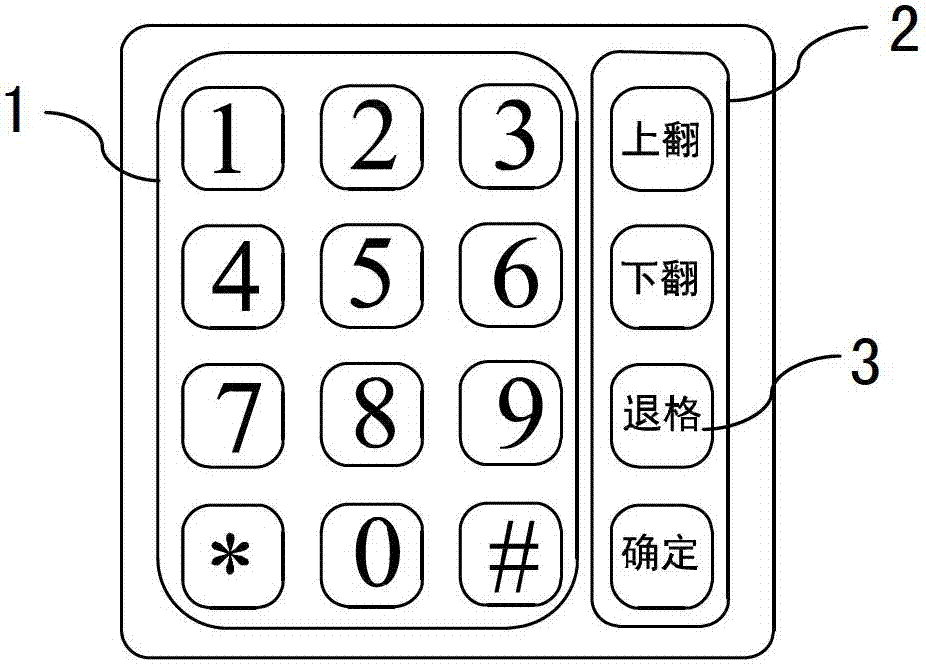

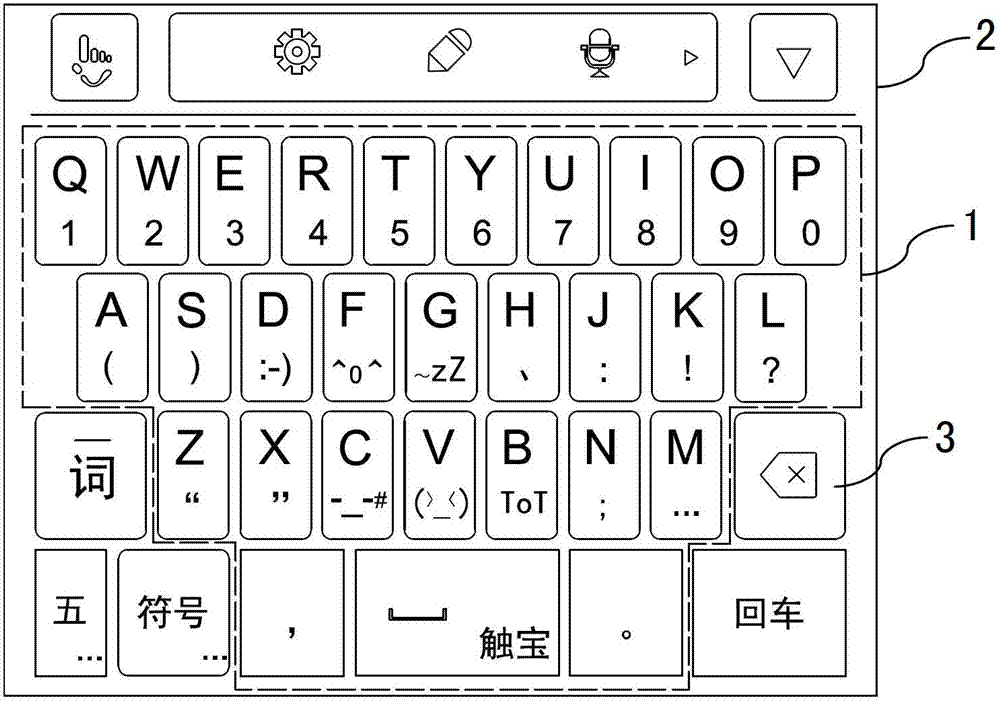

Method for simplifying Chinese-foreign language information input and judging whether input is right or not

InactiveCN103105942ADoes not affect handlingImprove accuracyInput/output processes for data processingVia rectumForeign language speaking

The invention discloses a method for simplifying Chinese-foreign language information input and judging whether input is right or not. A system firstly indicates Chinese-foreign language contents which need to be inputted by a student by using voices, or words or pictures on a screen; the student inputs codes which correspond to spelling of each Chinese pinyin of the to-be-inputted Chinese content according to a corresponding scheme between the pinyin or foreign language letters and the telephone press keys, or inputs codes which correspond to spelling of each word of the foreign language content, finally presses a confirm key and an input is over. The system compares the digital codes inputted by the student with digital codes which correspond to the spelling of each Chinese pinyin of the Chinese content which needs to be inputted, or with the digital codes which correspond to the spelling of each word of the foreign language content which needs to be inputted, if difference does not exist, then the input is right; if not, the input is wrong.

Owner:王湘民

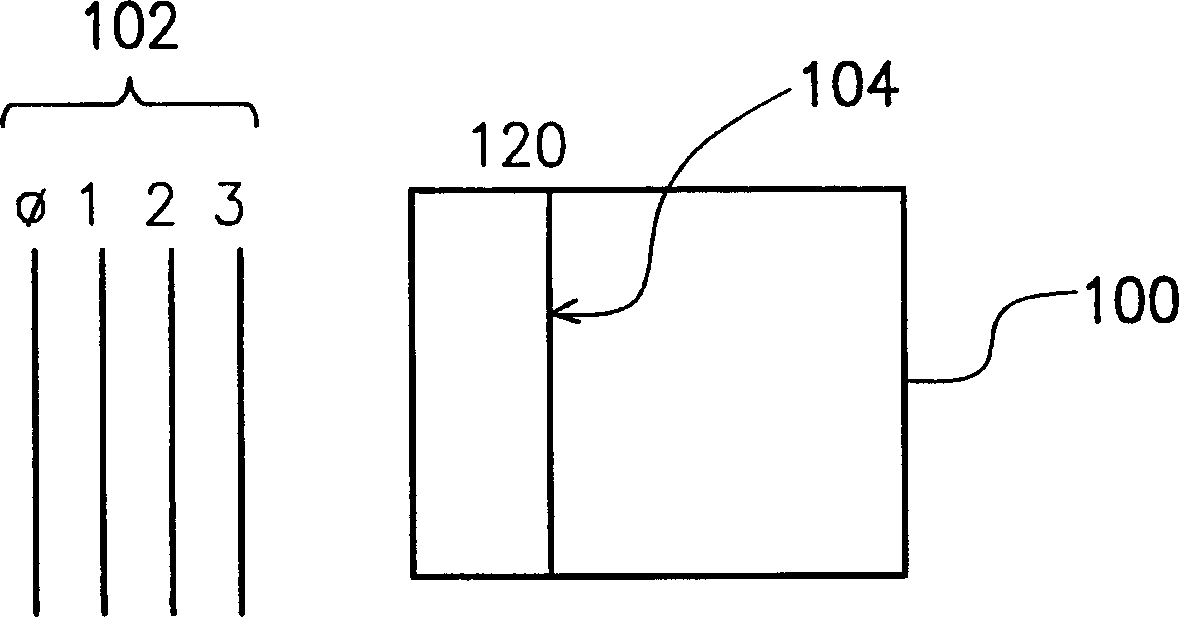

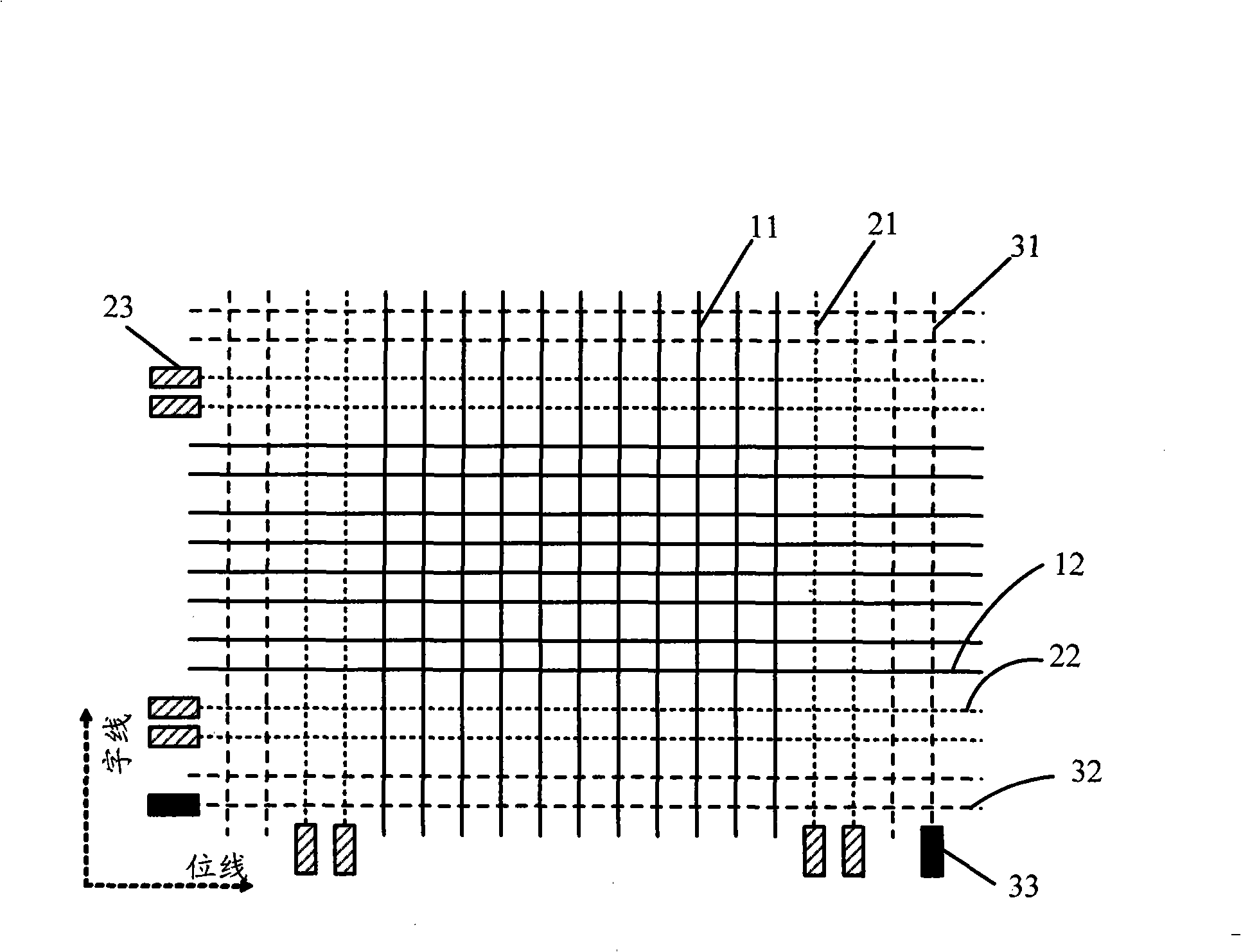

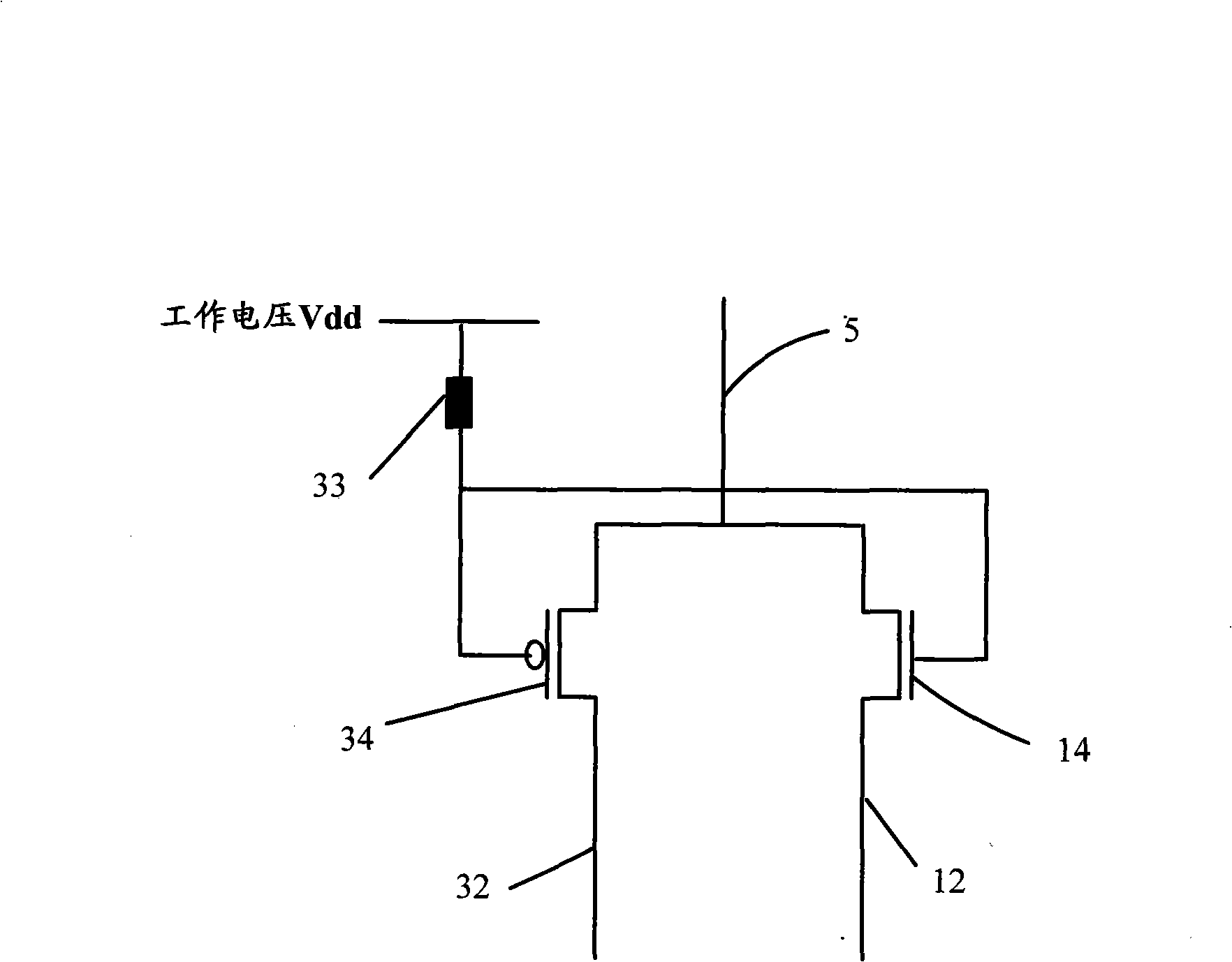

Method for verifying whether detection result of detection device is correct or not

InactiveCN101350226AEasy to interruptNo need to increase the areaStatic storageFocused ion beamVia rectum

The invention discloses a method for verifying whether a detection result of a detecting device is right, which relates to the detecting technology of semiconductors. The method comprises a clip which is equipped with a work area and a nominal area, the clip comprises a plurality of bit lines and word lines, the nominal area does not participate in a circuit work of the work area, and the bit lines or the word lines of the nominal area are connected with fuse wires and are connected with preinstall bit lines or word line circuits of the work area. The preinstall bit lines or the word lines of the work area fail through that the fuse wires are interrupted, the bit lines or the word lines of the nominal area which are connected with the fuse wires replace the preinstall bit lines or preinstall word lines of the work area, thereby obtaining an invalid practical physical address. The clip is detected by the detecting device, thereby outputting a detected physical address, and whether the detecting device is natural can be detected through comparing the practical physical address and the detected physical address. Compared with the prior art, the fuse wires are bigger and are conveniently interrupted by focusing ions or lasers. The design of a fuse wire circuit is added in the nominal area, and the whole area of the clip does not need to be increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP

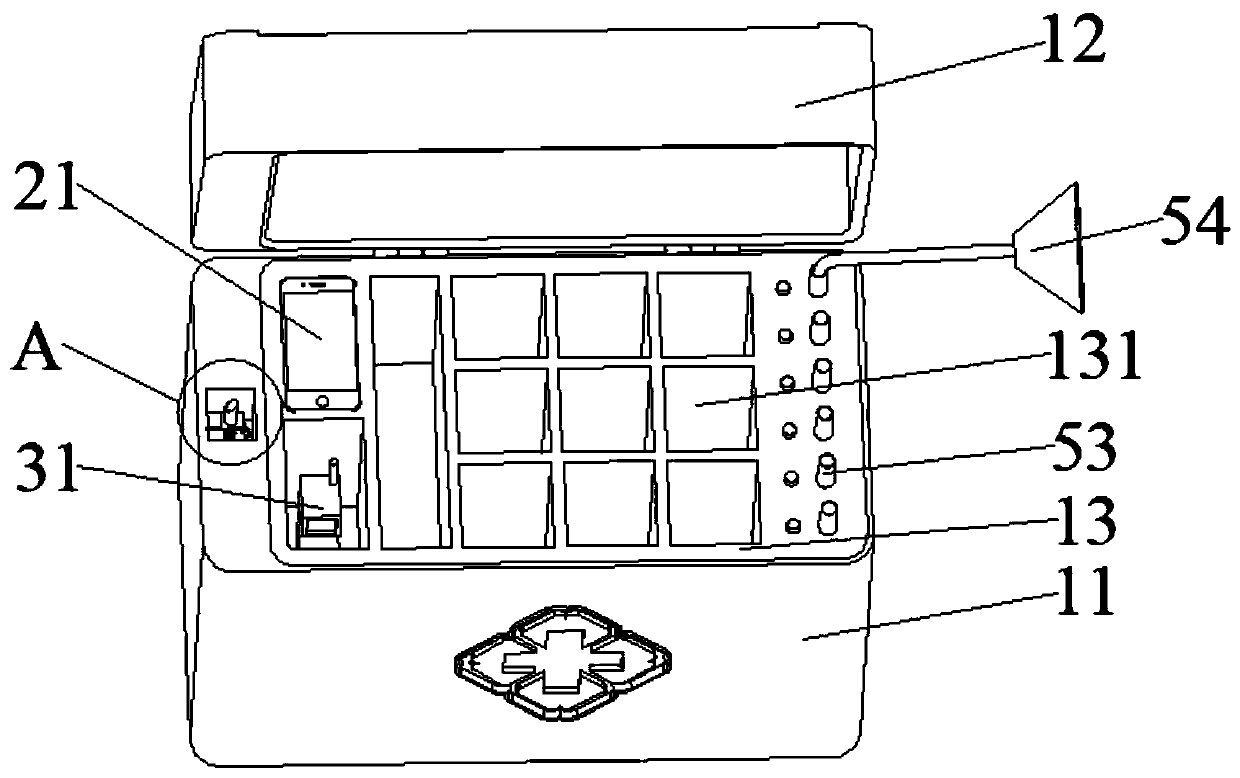

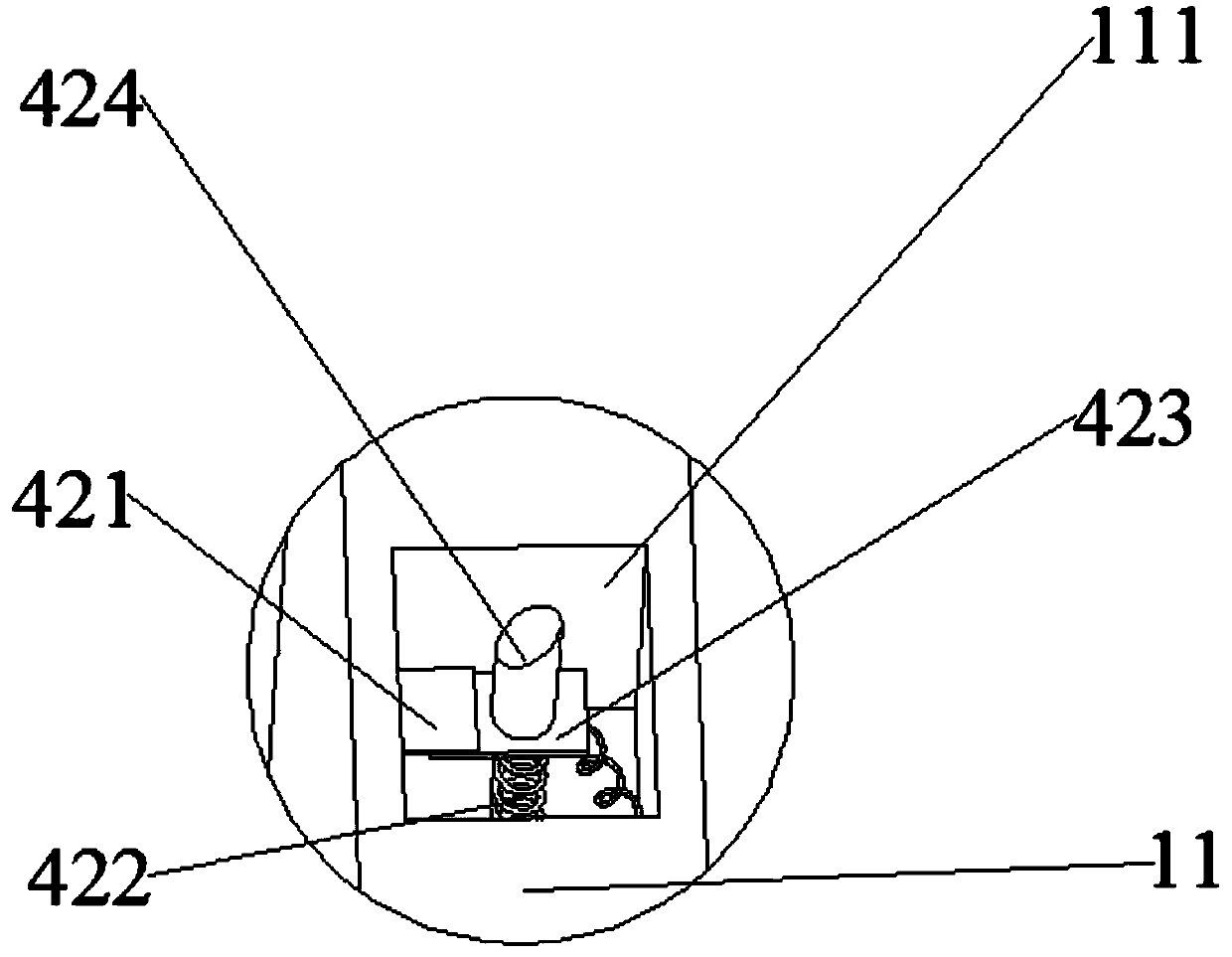

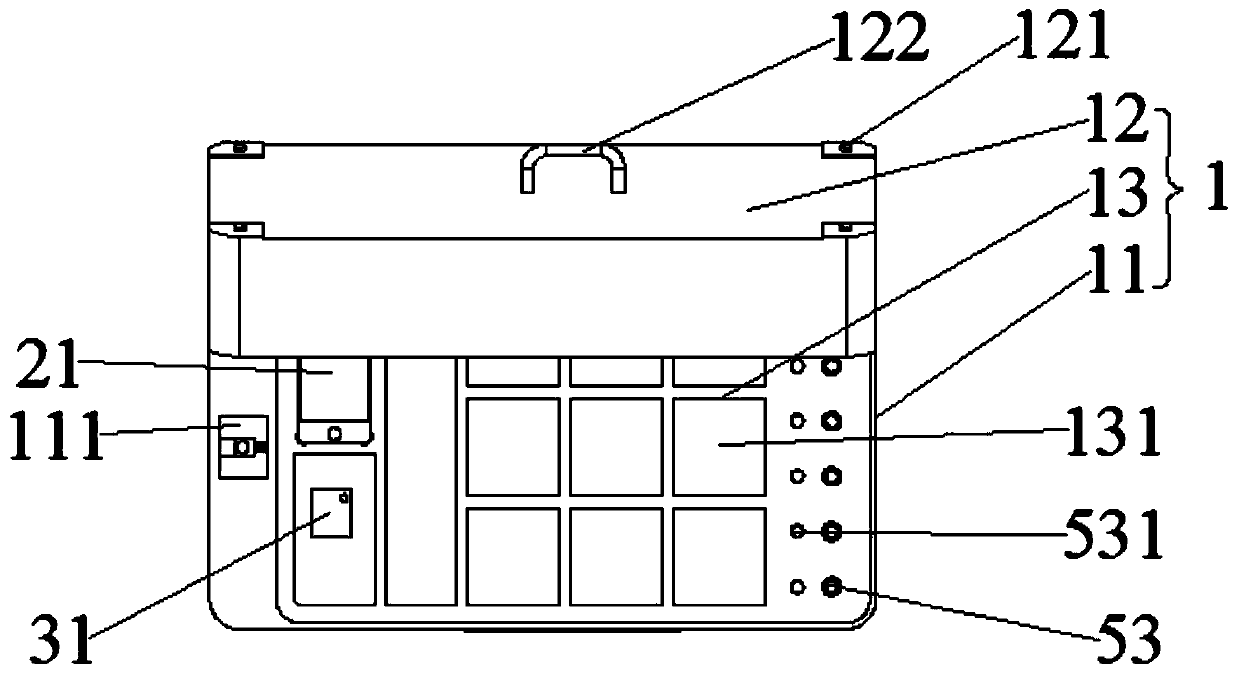

First-aid box

PendingCN110368199ASolve technical problems in emergency treatmentFirst-aid kitsVideo playerKit first aid

The invention provides a first-aid box and relates to the technical field of medical tools. The first-aid box comprises a first-aid box body and a video player; the video player is arranged inside thefirst-aid box body and is connected with the same; the video player is used to play videos of usages of various drugs and first-aid tools, and videos of emergency handling methods of various injuries. Before use of the first-aid box, the videos of usages of various first-aid drugs and first-aid tools and the videos of emergency handling methods of various injuries are pre-stored in the video player. In case that landslide occurs upon tunnel door closing, working personnel can turn on the video player such that the working personnel having a little understanding of injury emergency handling methods can use correctly and properly the drugs and first-aid tools in the first-aid box according to the videos played in the video player, and rescue emergently themselves or otherness in correct way.

Owner:CHINA FIRST HIGHWAY ENG +1

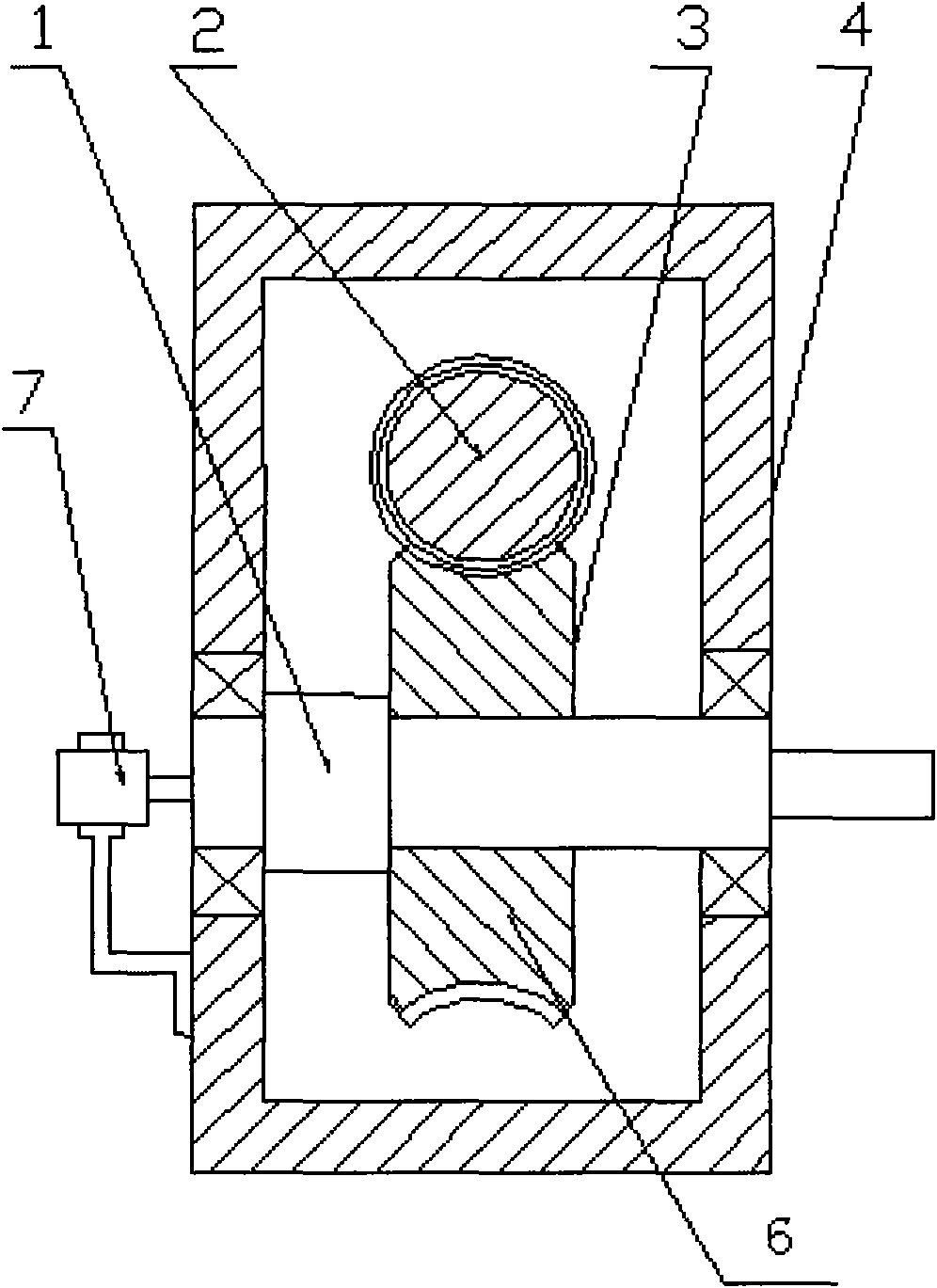

Novel multifunctional speed reducer

The invention relates to a novel multifunctional speed reducer. A turbine, a worm rod and an output shaft are arranged and fixed in a tank body by a property method. One end of an electromagnetic clutch is connected with one end of the worm rod. Simultaneously, the electromagnetic clutch is arranged and fixed on the tank body by a proper method. An output shaft of a motor is connected with the corresponding part of the electromagnetic clutch and is arranged and fixed by a proper method so that the output shaft, the tank body and the electromagnetic clutch form an fixed whole. A rotary encoder is connected with the output shaft and fixed on the tank body to form a whole. In the mechanism, the corresponding rotation amount is converted into the corresponding travel distance by the rotary encoder so as to control the motor and the electromagnetic clutch, thereby correspondingly controlling the electrical door.

Owner:孙淑勤

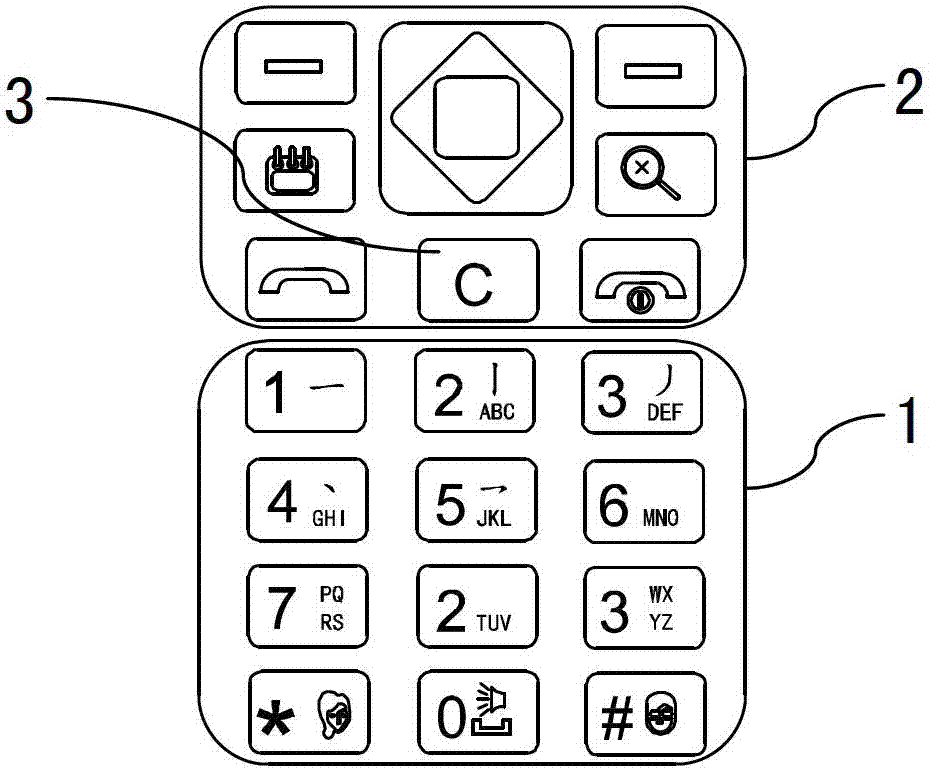

Method for judging whether input Chinese and foreign content is correct or not by voice process

InactiveCN102915657AFast judgmentDeepen impressionInput/output processes for data processingTeaching apparatusKey pressingVia rectum

Disclosed is a method for judging whether Chinese and foreign content inputted by using a telephone is correct or not by a voice process. The voice process includes the steps: 1.1 a system promotes Chinese or foreign content needing to be inputted by a user; 1.2 the user uses a following input method for inputting, clicks keys corresponding to strokes and stroke orders of the Chinese content required to be inputted according to a corresponding scheme of Chinese characters and the telephone keys, clicks keys corresponding to phonetic letters of the Chinese content required to be inputted according to a corresponding scheme of the Chinese character phonetic letters and the telephone keys, or clicks keys corresponding to letters in word spelling of the foreign content required to be imputed according a corresponding scheme of the foreign language letters and the telephone keys; 1.3 an input end key is pressed to show that inputting is ended; and 1.4 according to the corresponding schemes of the strokes, the phonetic letters and the foreign language letters with the keys, the system judges the input content is correct if inputted codes are as same as codes corresponding to the Chinese character strokes, the phonetic letters and the foreign language letters of the Chinese content required to be inputted, and otherwise false.

Owner:王湘民

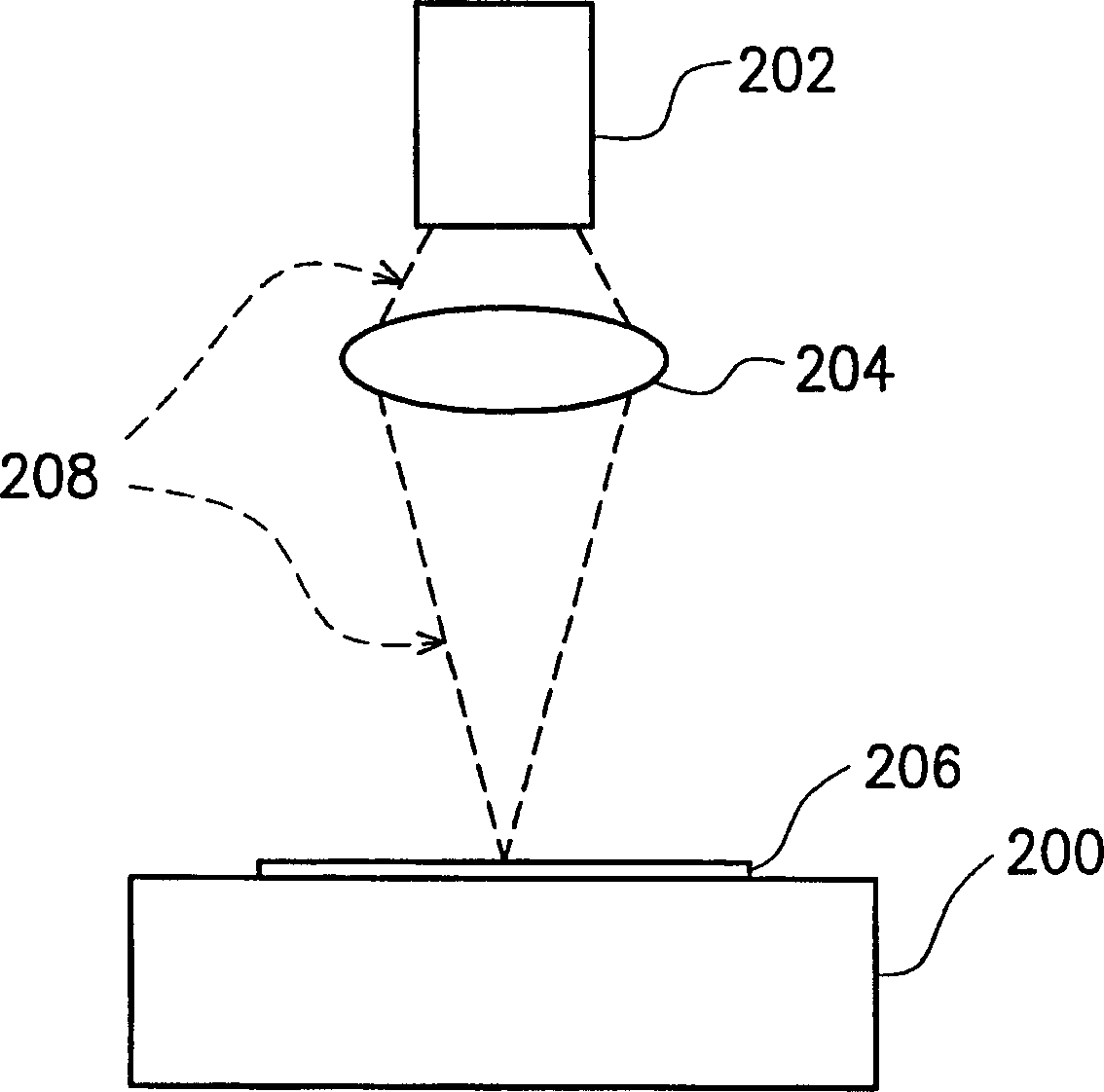

Method for identifying whether main reference plane position of silicon chip is correct or not

The invention provides a method for identifying whether the location of the main reference surface of a silicon wafer is right, with the following steps: (1) electrifying and preheating an X ray diffractometer; loosing a knob, displacing a detector to 26 DEG 40 MIN and locking the knob; configuring an angle presetting switch to 13 DEG 20 MIN, turning on a vacuum pump switch, putting a sample on a testing table, opening an X ray slot switch, and turning the sample to 13 DEG 20 MIN by hand-wheel; and fine turning the hand-wheel to maximize the indication of the pointer of an mA meter and pressing a reset button. And (2) loosing the knob, displacing the detector to 88 DEG and locking the knob; sticking the main reference surface upwards to a bracket, opening the X ray slot switch, and turning the hand-wheel till the pointer of the mA meter indicates the maximum. If the angle is in the range of 24 DEG 32 MIN plus or minus 7.5 DEG, the location of the main reference surface is right; and if the mA meter has no response or the angle surpasses the range of 24 DEG 32 MIN plus or minus 7.5 DEG, the location of the main reference surface is improper. The method for identifying whether the location of the main reference surface of the silicon wafer is right is simple and feasible with high accuracy.

Owner:浙江普通电子股份公司

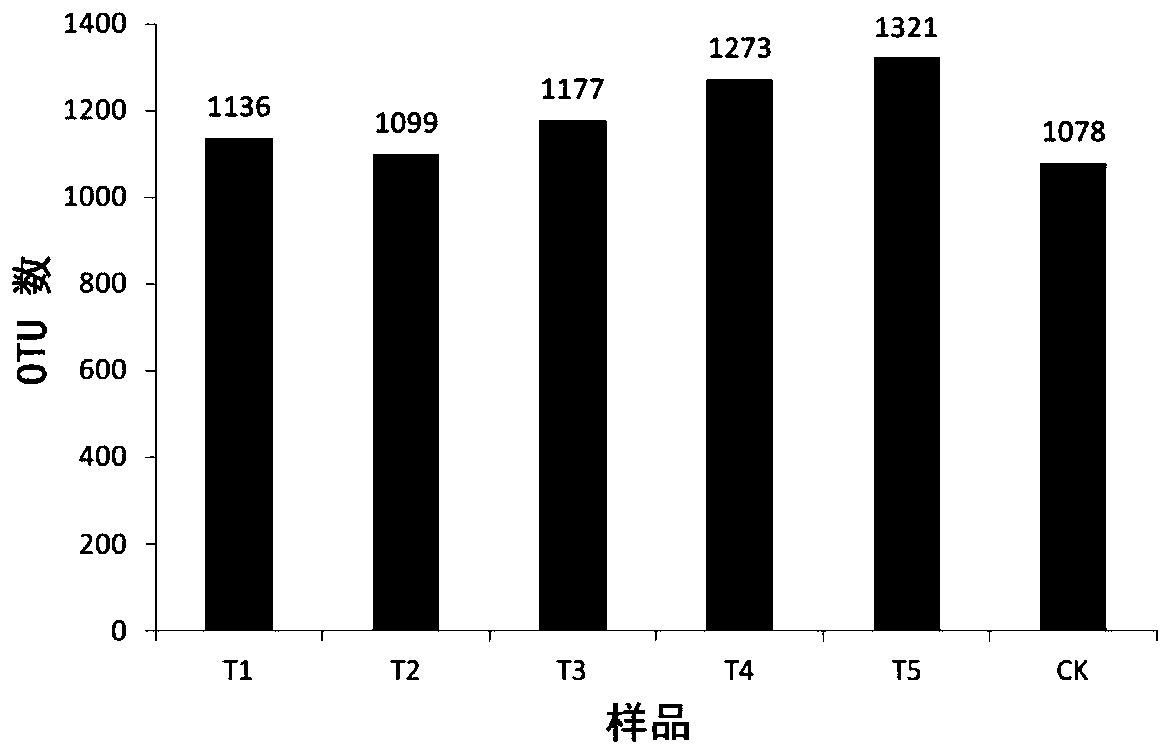

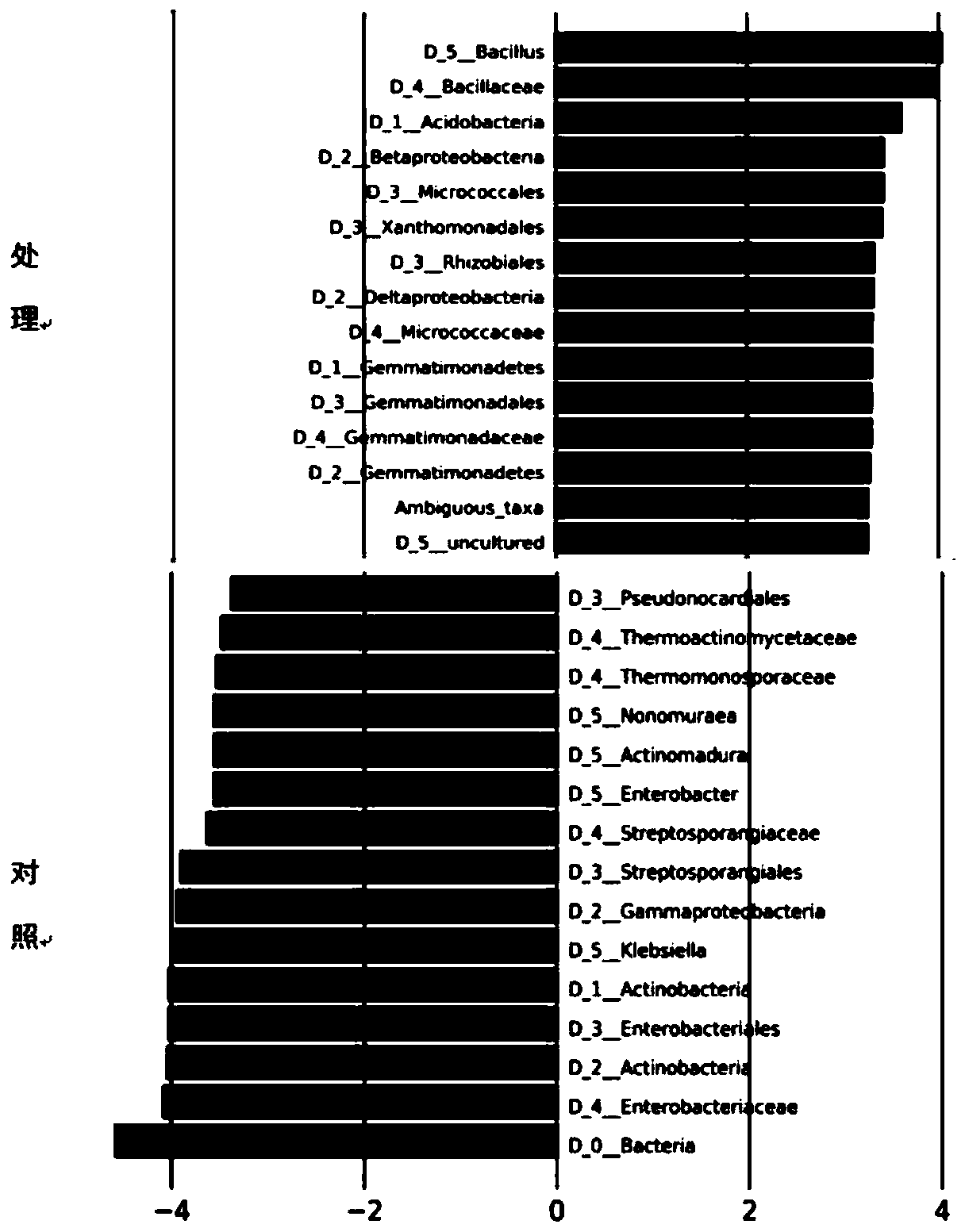

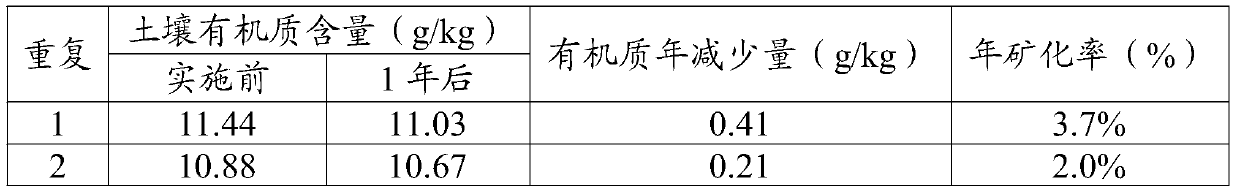

Soil improvement method

ActiveCN110622645AAvoid wastingImprove fertilityCalcareous fertilisersBio-organic fraction processingCommunity structureCrop cultivation

The invention belongs to the field of soil improvement, and particularly relates to a soil improvement method which includes the steps: performing organic matter biological enhanced humifying improvement on soil at the early stage of crop cultivation; performing organic matter balance mineralization improvement on the soil at the middle and later stage of crop cultivation. The soil improvement method can promote organic matters to enter the soil to form humic substances at the early stage of crop cultivation, redundant nutrients are reserved, soil organic matter balance mineralization is facilitated under guarantee of suitable time and correct method at the middle and later stage of crop cultivation, the nutrients are released again, and balance of supply and demand of the nutrients in theoverall process of plant growth is ensured. According to the soil improvement method, a soil granular structure and a soil microbial community structure can be improved when soil fertility is effectively improved, fertilizer consumption is reduced, and high-yield and high-quality agricultural production is achieved.

Owner:BEIJING GOLDENWAY BIO TECH

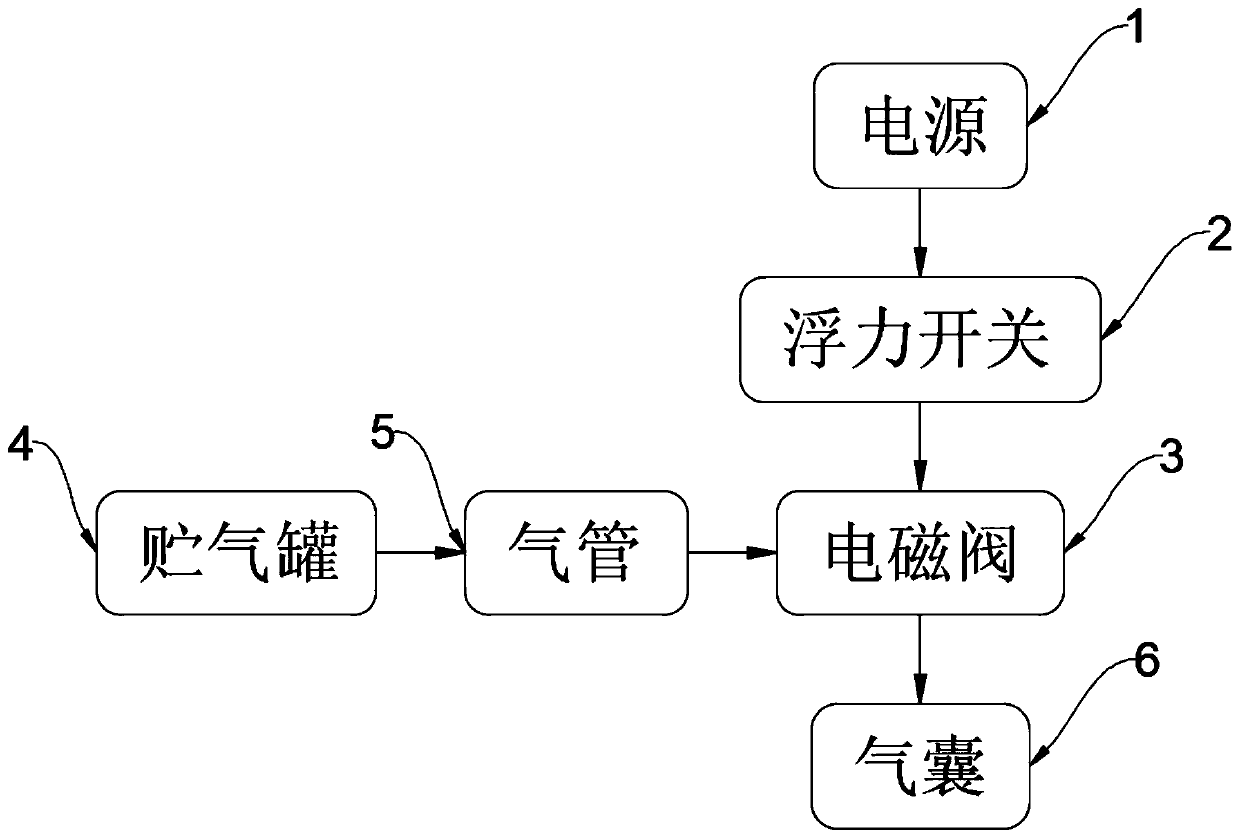

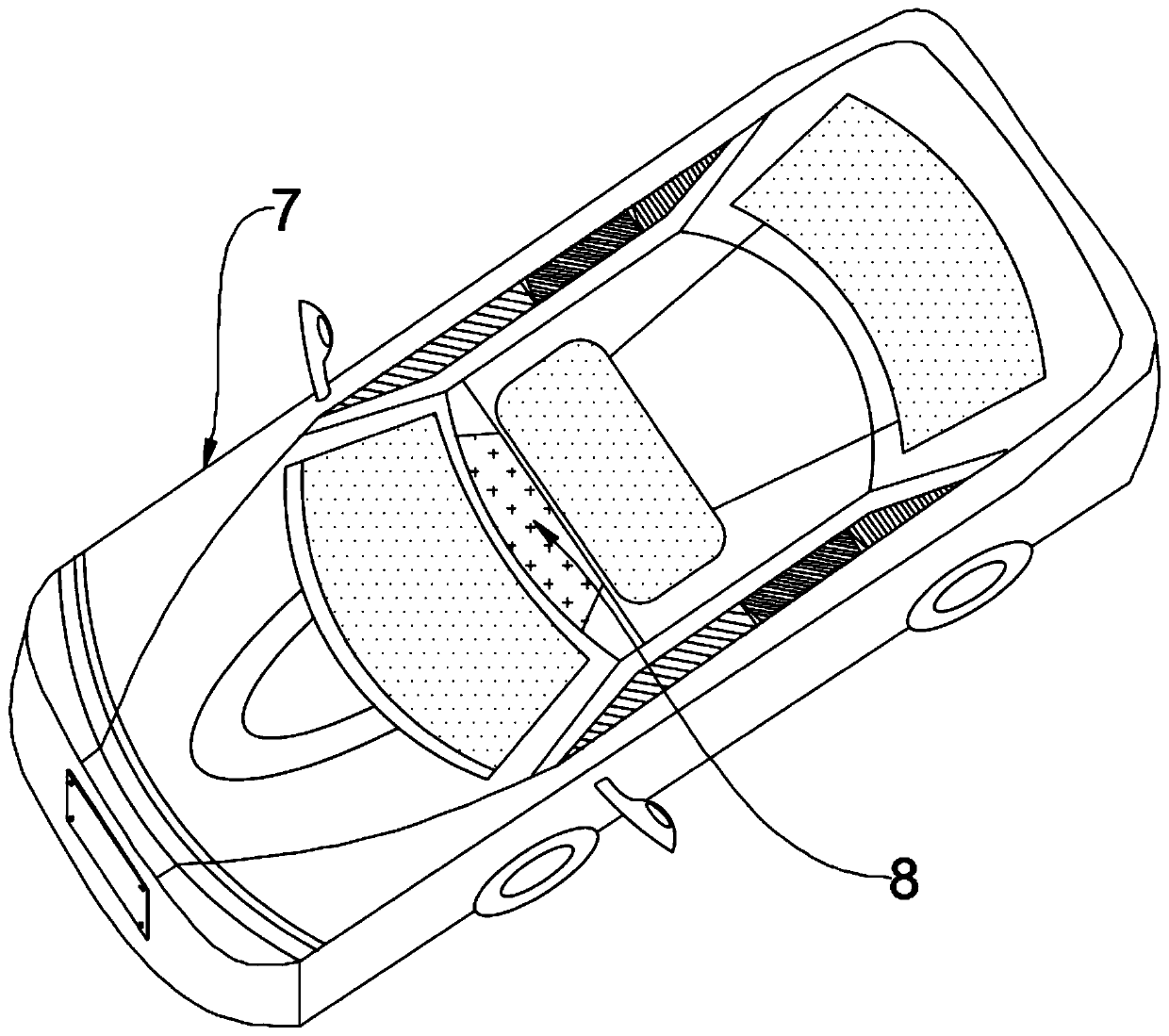

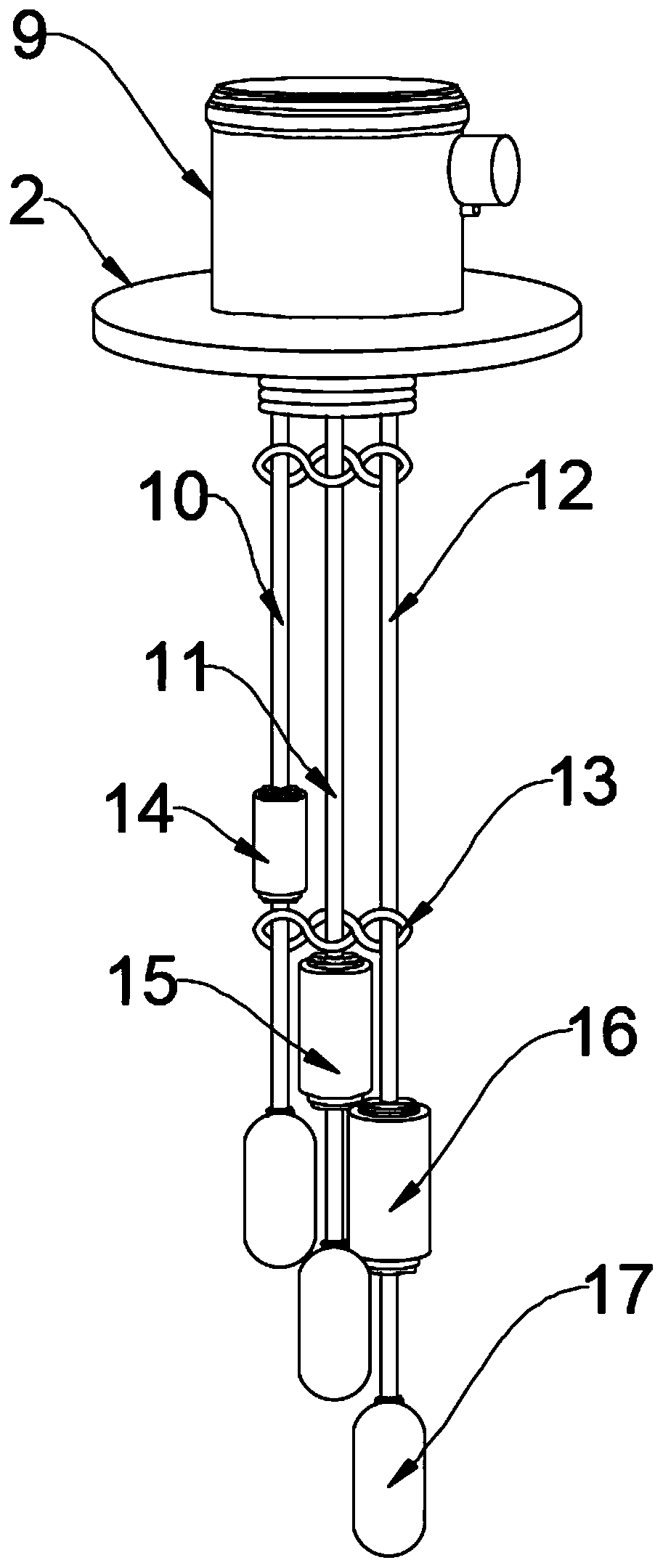

Vehicle drowning self-floating lifesaving device

ActiveCN110053576AEasy to useTo achieve life-saving effectPedestrian/occupant safety arrangementVia rectumEngineering

The invention discloses a vehicle drowning self-floating lifesaving device, and relates to the related field of self-floating lifesaving devices. The vehicle drowning self-floating lifesaving device aims to solve the problems that in the prior art, a driver does not correctly handle emergency situations during driving, cannot timely adopt correct methods to avoid drowning caused by danger or accidents, and cannot ensure the safety of the driver and passengers on a vehicle. The output end of a power supply is connected with the input end of a buoyancy switch, the output end of the buoyancy switch is connected with the input end of an electromagnetic valve, the input end of the electromagnetic valve is connected with the output end of an air pipe, the input end of the air pipe is connected with the output end of an air storage tank, the output end of the electromagnetic valve is connected with the input end of an air bag, the vehicle is provided with an air bag storage area, the buoyancyswitch comprises a switch electronic component outer shell, and a first communicating pipe, a second communicating pipe and a third communicating pipe are arranged at the lower end of the switch electronic component outer shell.

Owner:江苏航运职业技术学院

Alpha type recombined human interferon suppository and producing process

InactiveCN1457883AAvoid painAvoid reactionPeptide/protein ingredientsDigestive systemDiseaseIntestinal tract diseases

The present invention provides type-Alpha recombinant human interferon suppository and its production process. After polyglycol products with different molecular weight are mixed, high pressure sterilized and cooled to 40-56 deg.c, the interferon liquid is added to a content of 500,000-10,000,000 IU / ml, with the mixture being packed. Via rectum or anus administration, the medicine absorbed by rectum mucous membrane is transferred to whole body via rectum vein, portal vein and liver; or via rectum vein, anal canal vein, inferior canal vein and blood circulation system. Or, the medicine may be absorbed by rectum mucous membrane and lymph system. Local administration may reach relatively high local interferon level essential for treating viral intestinal tract disease.

Owner:CHANGCHUN CHANGSHENG GENE PHARM CO LTD

Mesilate phentolamine suppository and its preparation

InactiveCN1456155AAvoid stimulationEasy to absorb and playOrganic active ingredientsSuppositories deliverySide effectVia rectum

A phentolamine mesylate in the form of suppository for treating male sexual disfunction and female asexuality by applying it via rectum or vagina is disclosed. Its advantages are high curative effect and low toxic by-effect.

Owner:武汉同药物业管理有限公司

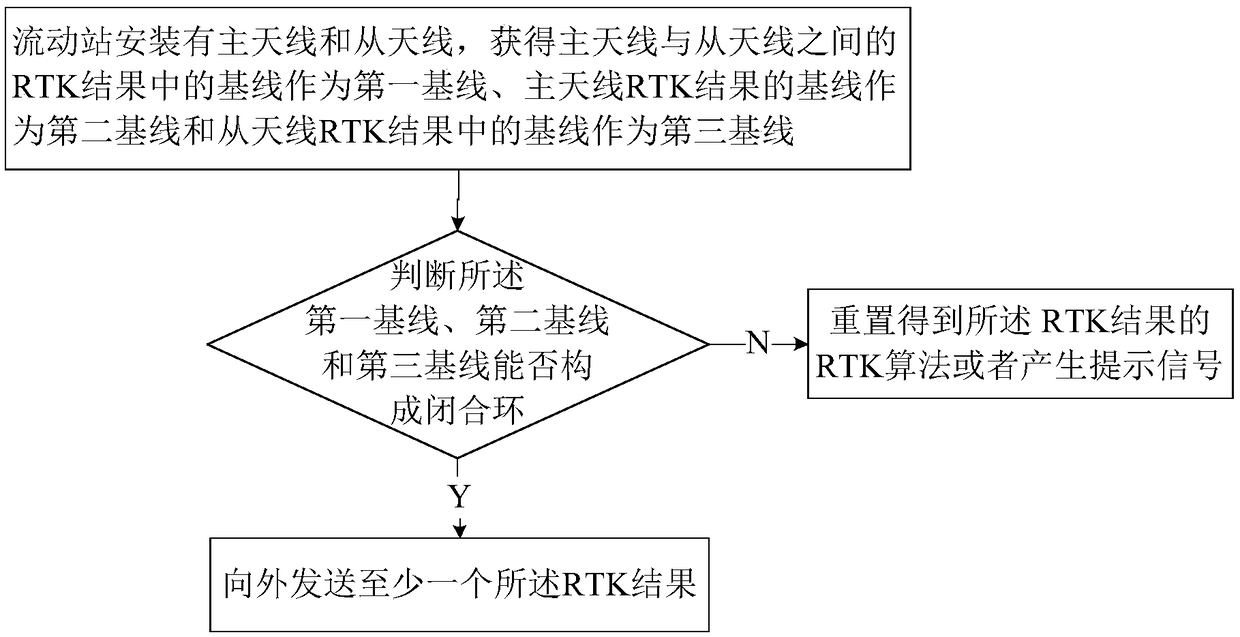

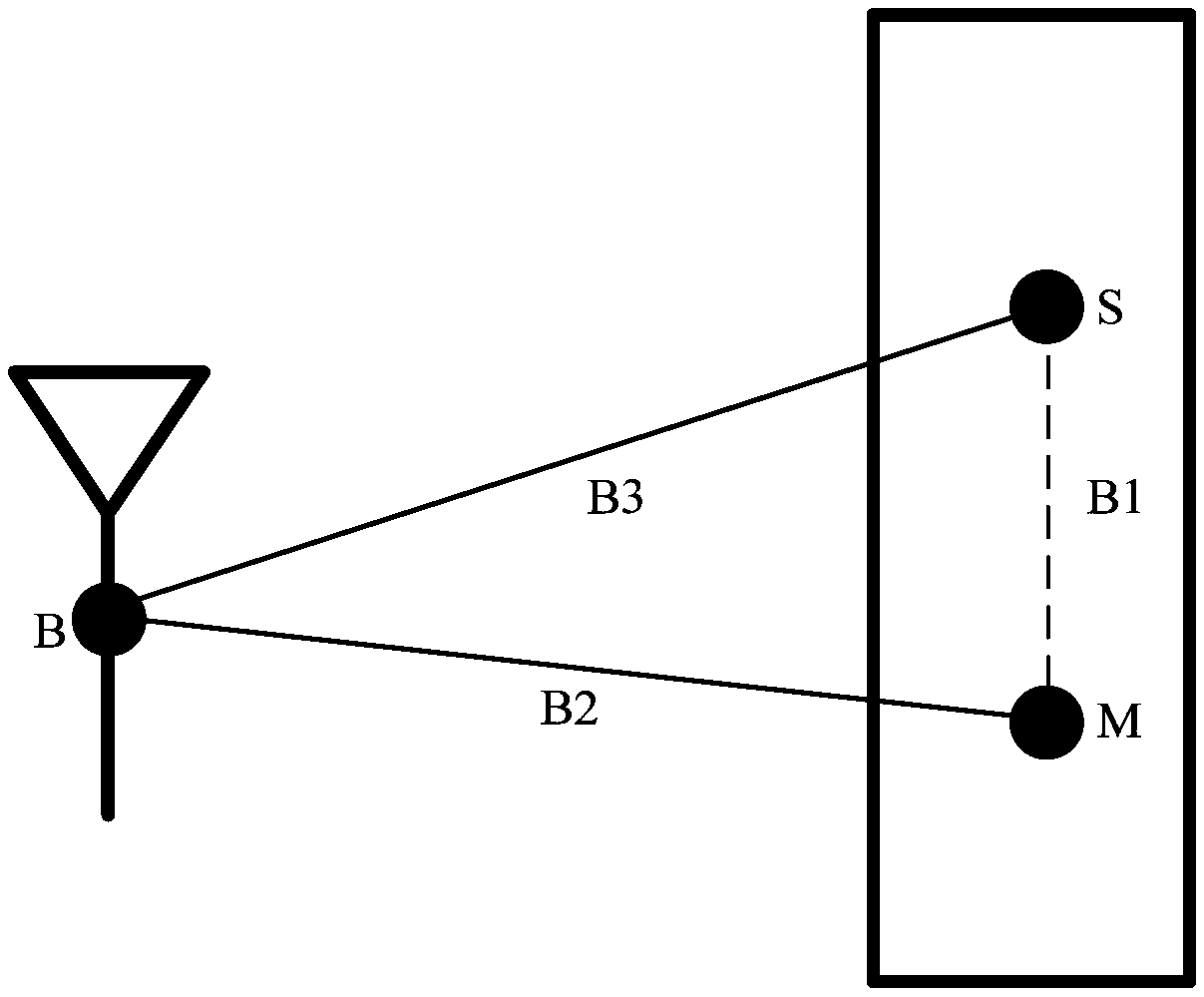

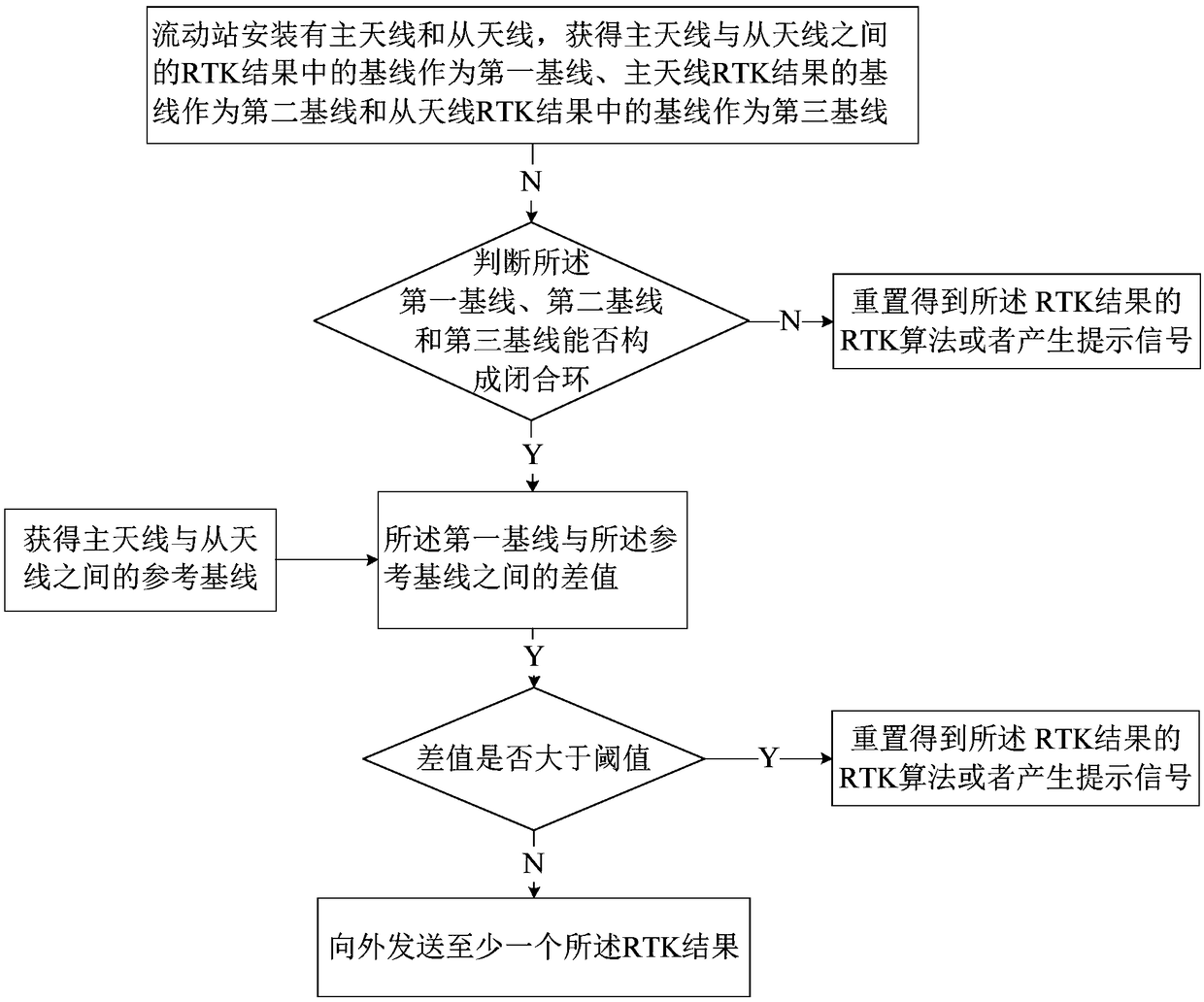

Method for judging correctness of RTK result, OEM board card, receiver and storage medium

ActiveCN109490915AAccurate judgmentPrecise referenceSatellite radio beaconingVia rectumComputer science

The invention discloses a method for judging correctness of an RTK result, an OEM board card, a receiver and a storage medium. The method comprises the following steps: obtaining RTK results of each antenna and RTK results between the antennas, and obtaining baselines of the respective RTK results from the RTK results of any two adjacent antennas and the RTK results between the two antennas; judging whether baselines in the three RTK results form a closed ring or not, resetting an RTK algorithm for obtaining the RTK results or generating a prompt signal if the baselines in the three RTK results cannot form the closed ring, and sending at least one RTK result outwards if the baselines in the three RTK results can form the closed ring. The method for judging correctness of an RTK result canaccurately and quickly judge whether the RTK result is correct or not.

Owner:COMNAV TECH

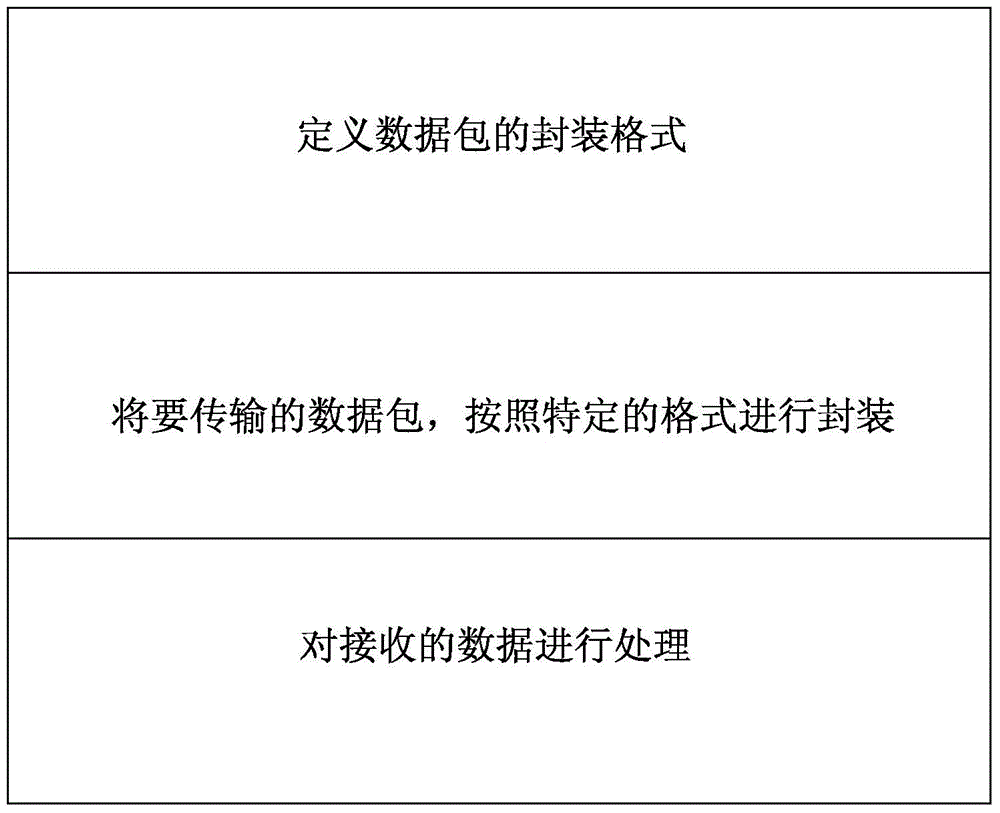

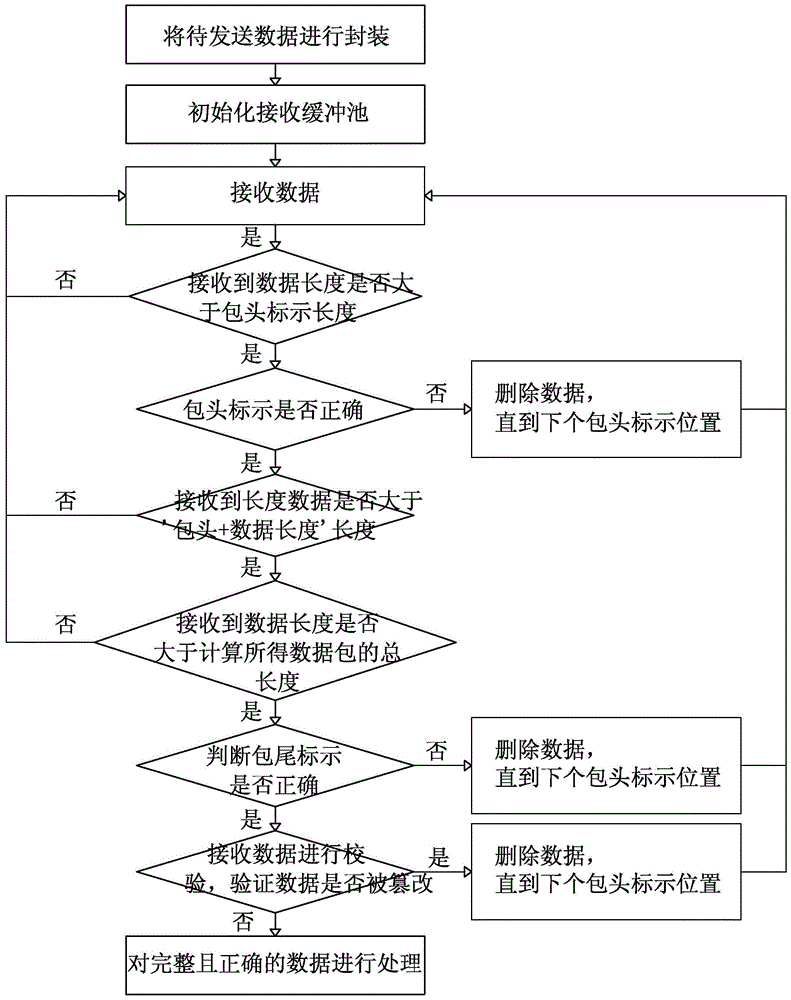

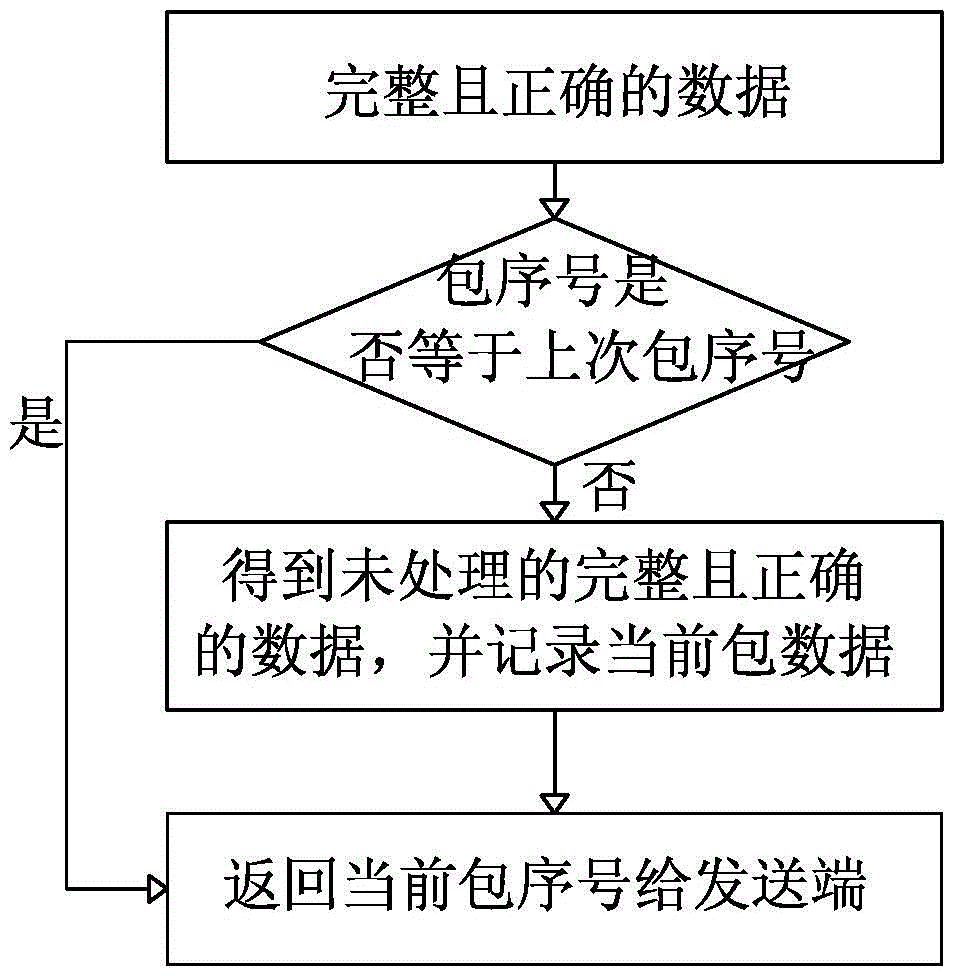

A method to ensure the integrity and correctness of tcp communication data

The present invention is a method for ensuring the integrity and correctness of TCP communication data, comprising: step 1: defining the TCP packet transmission format according to the actual situation, and the TCP data packet is composed of packet header+data length+packet sequence number+data+data check code+packet tail sequence The order is formed sequentially; Step 2: The client or server encapsulates the data to be sent into a complete data packet according to the method of Step 1; Step 3: After receiving the data, the client or server performs data integrity and correctness verification according to the encapsulation format , and return the current packet sequence number to the sender.

Owner:CHENGDU FORWARD TECH

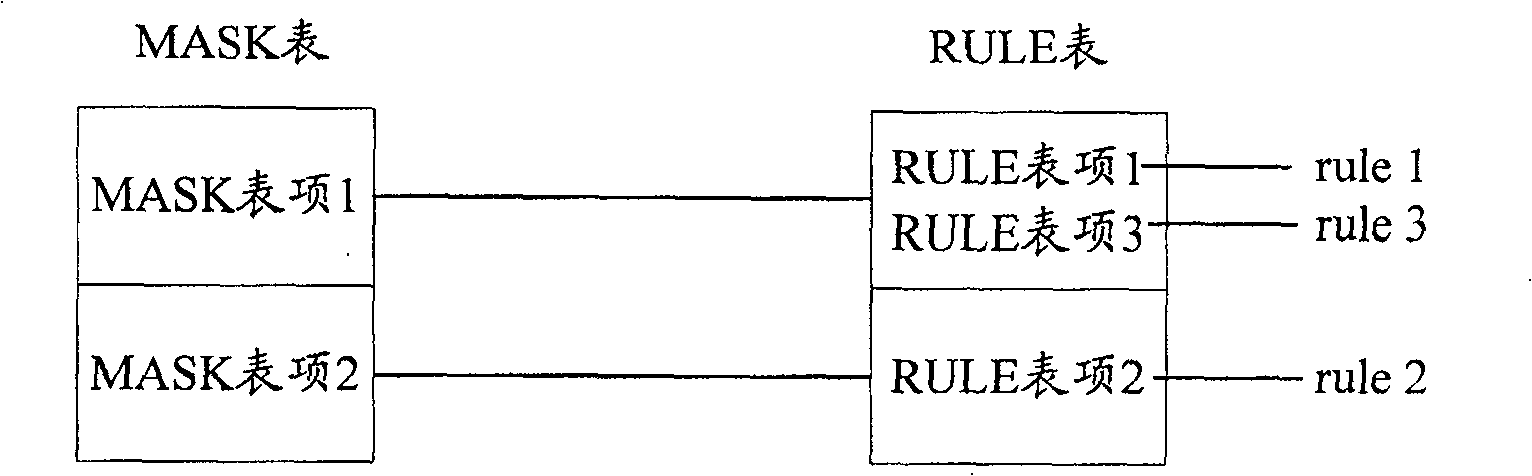

Method, device and system for assuring correct execution

ActiveCN100531218CCorrect business processEnsure correct executionData switching networksComputer hardwareVia rectum

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

A manual reversing insulin mixing device

InactiveCN103977732BMix well and correctlyAvoid shortagesRotating receptacle mixersVia rectumDrive shaft

A manual-reversing insulin uniformly-mixing device comprises a base provided with a boss, a concave rotary table and a uniformly-mixing barrel; a supporting column for supporting the bottom of the concave rotary table is arranged on the base; the edge of the bottom of the concave rotary table is rotatingly connected with the edge of the boss on the base through a rotary shaft, so as to achieve a fact that after the concave rotary table rotates 90 degrees around the rotary shaft, one outer lateral wall of the concave rotary table is fitted with the top of the boss; a medicine basket filled with insulin is arranged in a barrel body; a barrel cover is provided with a motor II; a transmission shaft of the motor II passes through the barrel cover and is connected with the medicine basket, so as to make the medicine basket rotate around a rotary shaft II mounted at the bottom of the barrel body under the action of the motor II. Through a plurality of simple components, a large amount of insulin is mixed uniformly according to a correct method before a patient is injected, and an insulin short supply problem is avoided from appearing.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com