Novel brake mechanism of rigid clutch press

A technology of rigid clutch and braking mechanism, which is applied in the field of forging machinery, can solve the problems of large energy consumption, low life, and large motor load, and achieve the effect of overcoming large motor load and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

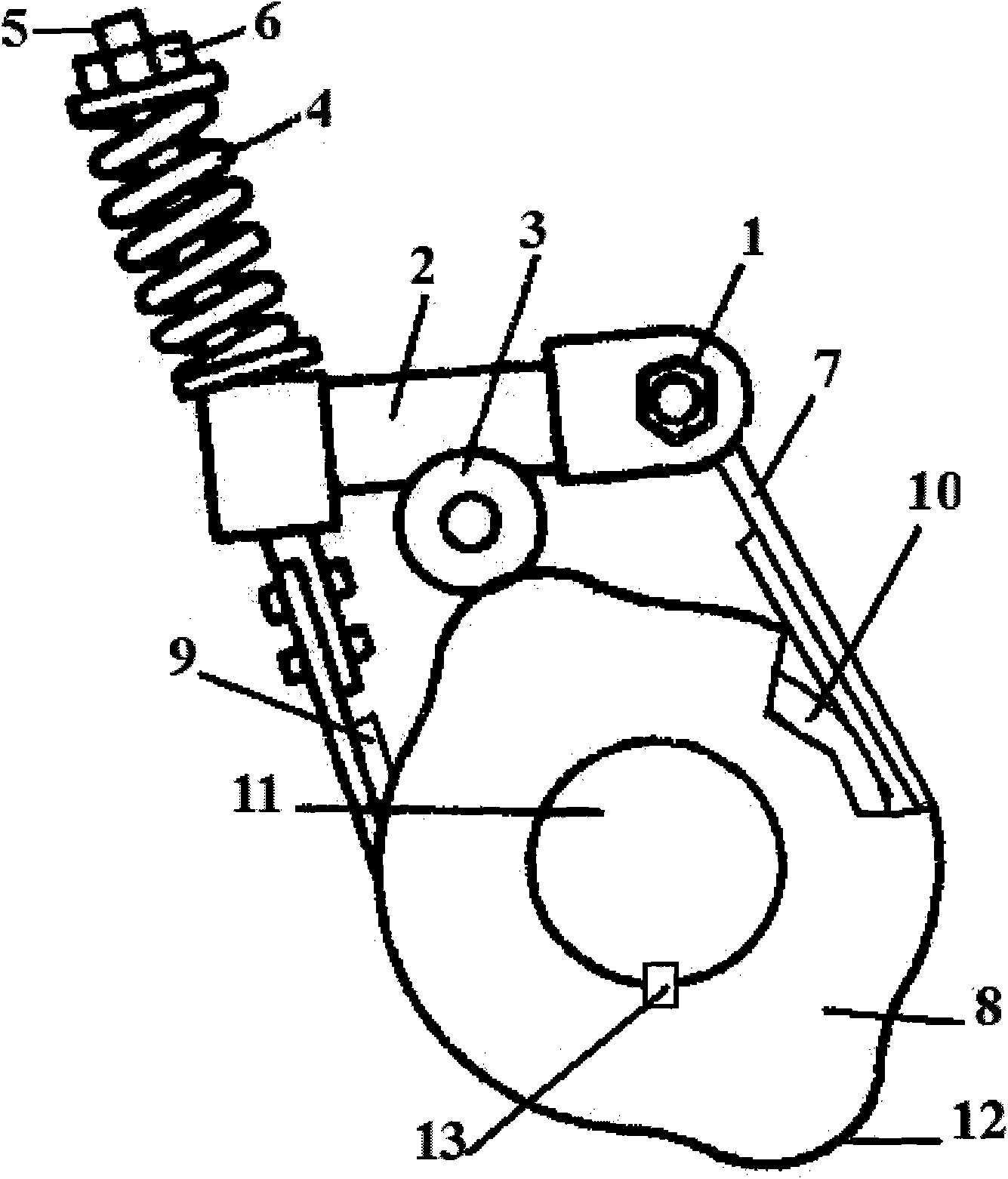

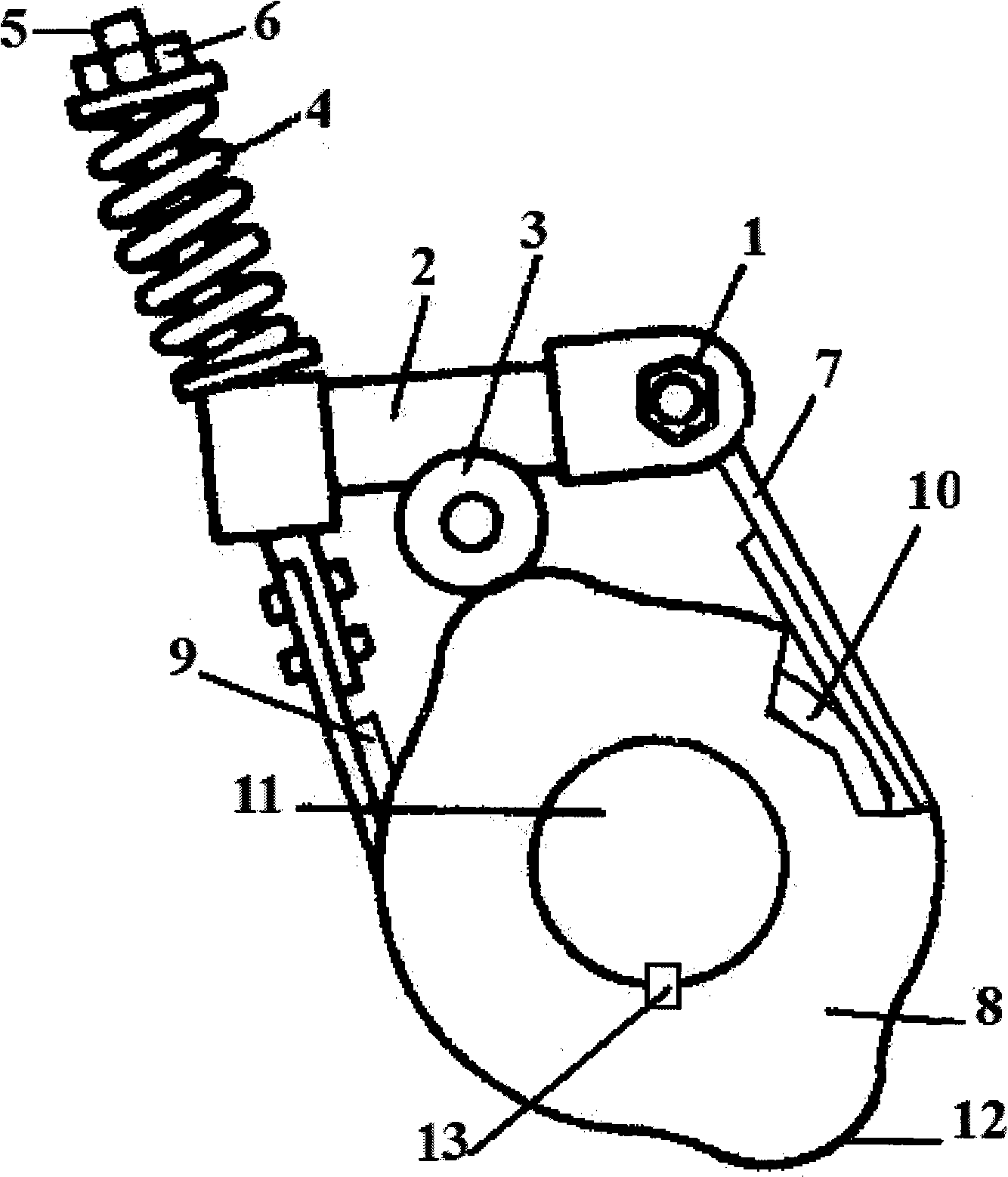

[0009] Install the brake wheel (10) and the cam (8) on the crankshaft (11) from the inside to the outside in turn, and fix them on the crankshaft (11) with the key (13). When installing, make the convex arc ( The position of 12) corresponds to the position of the top and bottom dead center of the crankshaft (11). Use the pin shaft (1) to install and fix the lever (2) on the top of the body. Make sure that the lever rotates flexibly around the pin shaft (1) during installation. ; Use the correct method to install and fix the roller (3) at the appropriate place in the middle of the lever (2), rivet the friction belt (9) on the brake belt (7), and fix the brake belt (7) One end is hinged with the pin (1), and the other end is fixed with the tension rod (5) in a proper way. Pass the tension rod (5) through the through hole on the lever (2) and put it on the body For the spring (4), use the nut (6) to properly compress the spring (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com