Method for removing chloride ions from paper-making reconstituted tobaccos

A technology for reconstituting tobacco leaves and removing chlorine, which is applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of reducing the utilization rate of raw materials, the loss of the content of effective tobacco components of aroma substances, and increasing the loss of effective components, and achieves dechlorination. The effect of reducing the treatment cost, improving the comprehensive utilization rate, and reducing the chloride ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

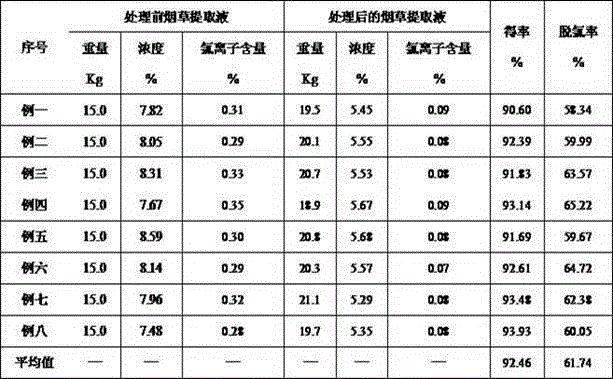

Examples

Embodiment Construction

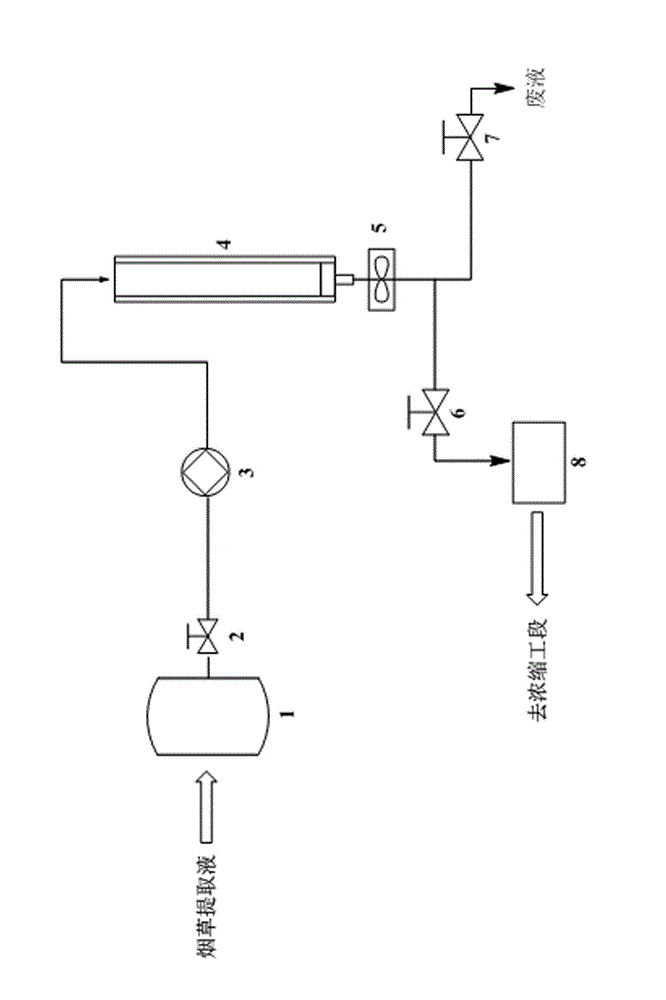

[0026] The implementation of the technical solution is further described in detail in conjunction with the accompanying drawings:

[0027] Load the activated anion exchange resin into the ion exchange column; liquidate the tobacco extract after preliminary filtration into the ion exchange column; add the self-made compound formula acid to adjust the pH value, and the obtained liquid enters the next stage of concentration process.

[0028] As mentioned above, the dechlorination process steps of a kind of papermaking method tobacco extract of the present invention are:

[0029] (1) Transport the tobacco extract with a concentration (solid content) of 4%~10% to the storage tank, and proceed to the next step when the temperature is controlled at 40~45°C;

[0030] (2) Transport the tobacco extract in step (1) to an anion exchange column, control the temperature at 40-45°C, and allow the tobacco extract to completely pass through the anion-exchange resin within 5-7 minutes;

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com