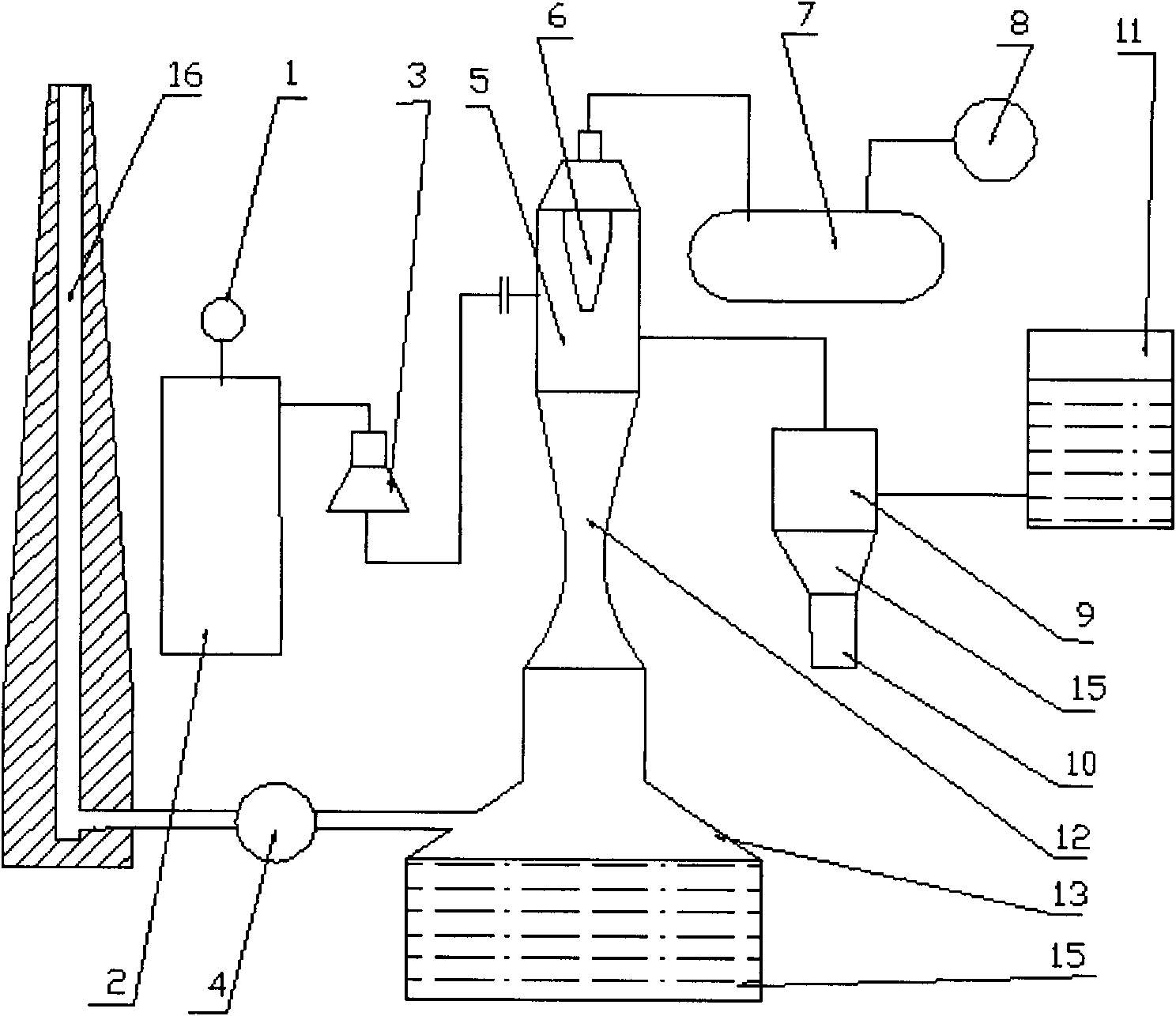

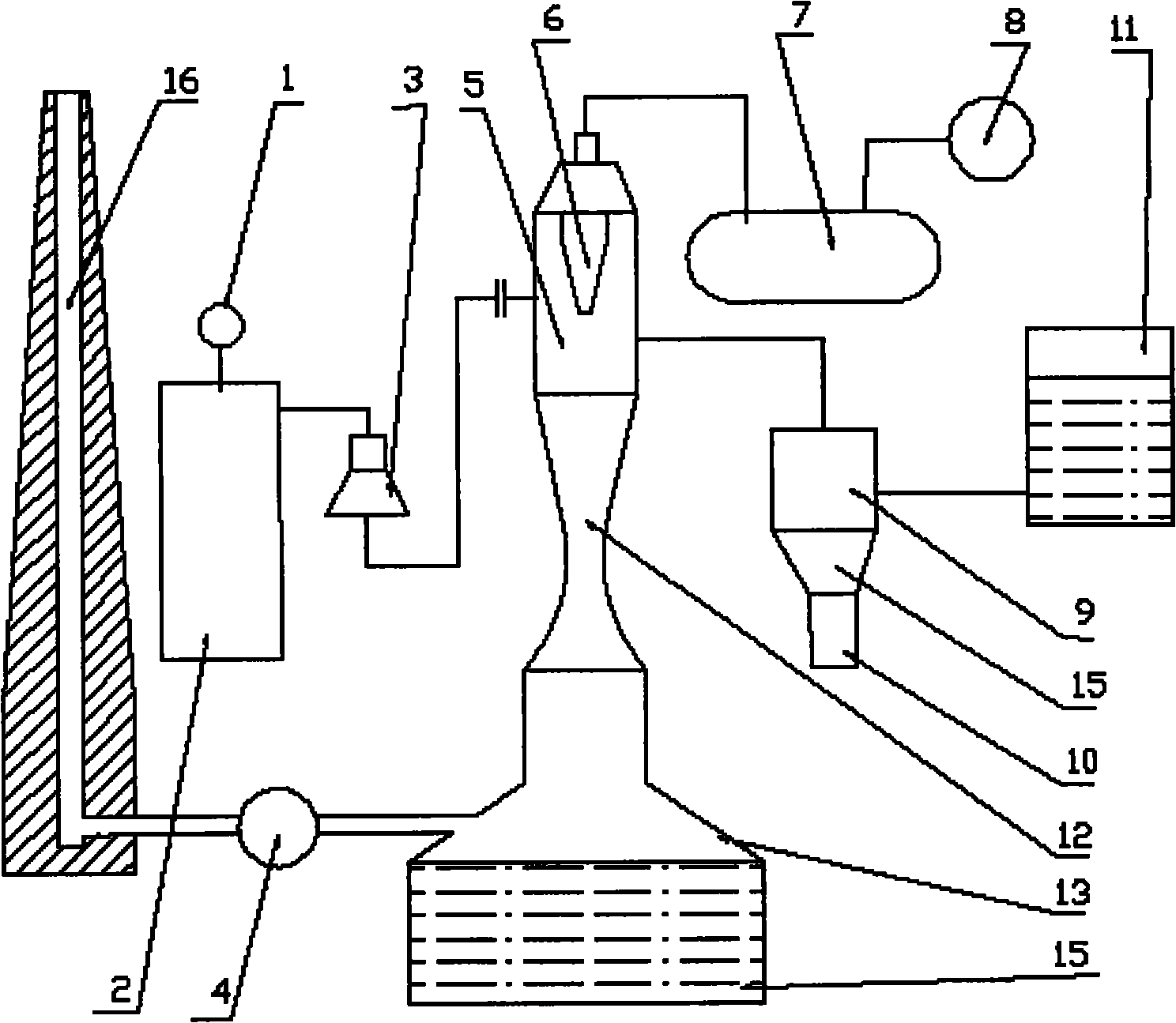

Novel boiler smoke prevention and dust control device

A technology for smoke and dust removal and boilers, applied in the field of environmental sanitation equipment, can solve the problems of large water consumption, difficult cleaning, and high use costs, and achieve the effects of good purification quality, high purification efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Correctly install the designed nozzle (6), negative pressure chamber (5) and Qiuvent tube (12) in the negative pressure chamber (5), and install the upper Qiuvent tube (12) at the lower end of the negative pressure chamber (5). ); the Qiuwen pipe (12) and the fume hood (13) are correctly installed, the fume hood (13) is covered on the circulating pool (14) in an appropriate way, and the centrifuge ( 3) link to each other with chimney (16). Connect the inlet of the centrifuge (3) to the boiler body (2) and the outlet to the negative pressure chamber (5) with a pipe of appropriate caliber. The air reservoir (7) is connected to the air compressor (8) and the nozzle (6) respectively with pipelines of appropriate caliber. Install and fix the transducer (15) and the spray chamber (9), and install and fix the ultrasonic generator (10) and the transducer (15) in a correct way. The spray chamber (9) is communicated with the replenishing water tank (11) and the negative pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com