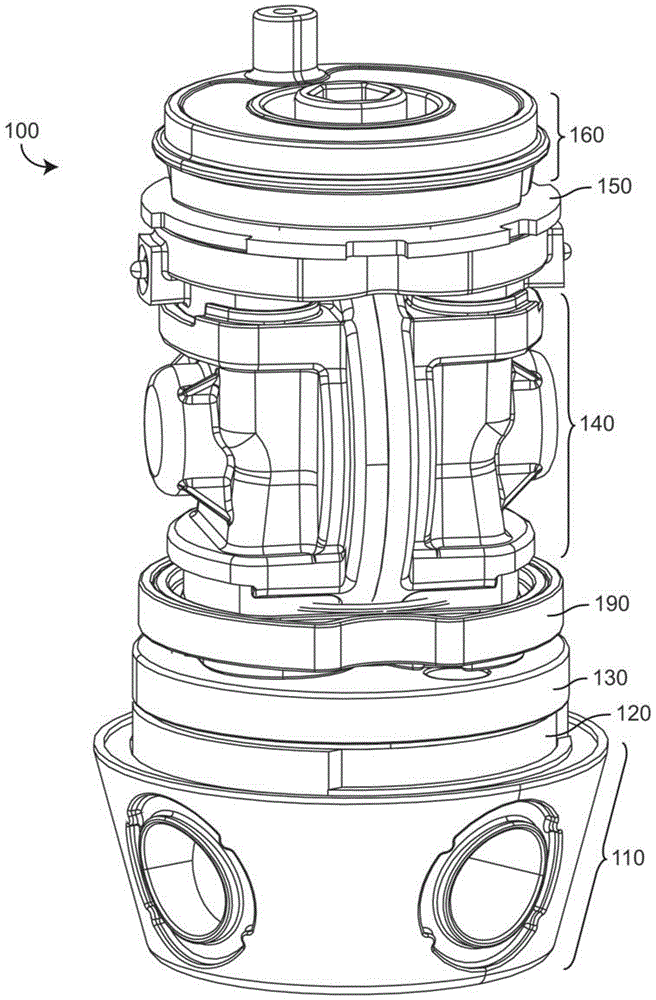

Concentric diverter spool

A diverter valve, concentric valve technology, applied in multi-port valves, valve devices, instruments, etc., can solve the problem of not being able to set the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

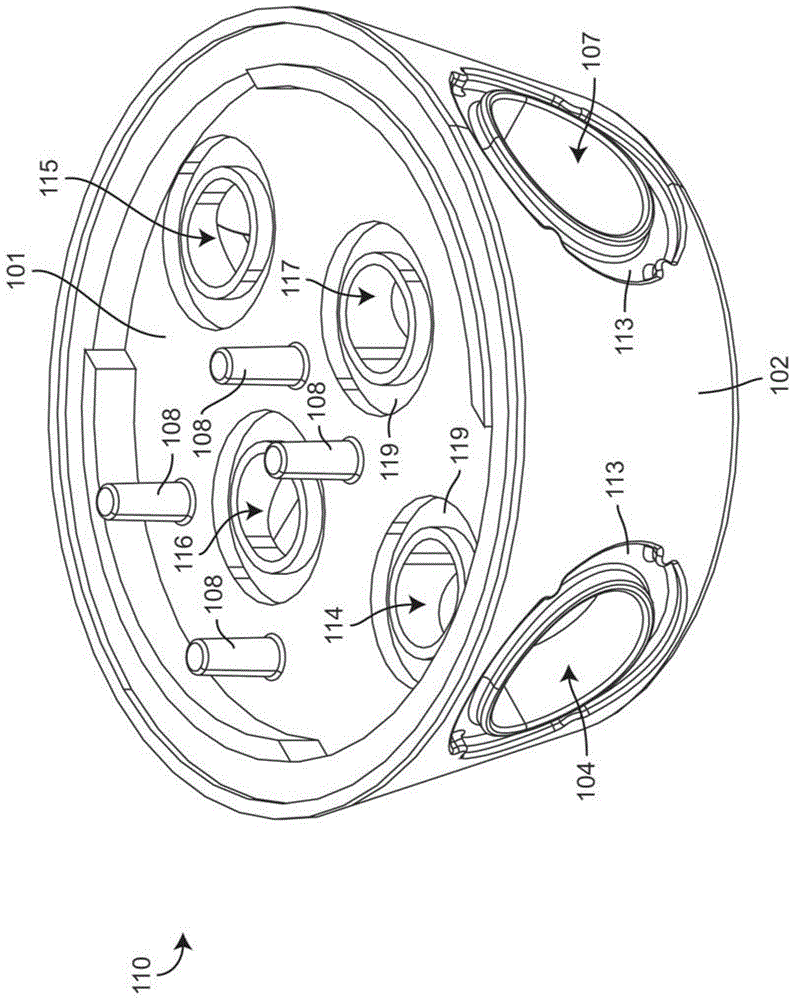

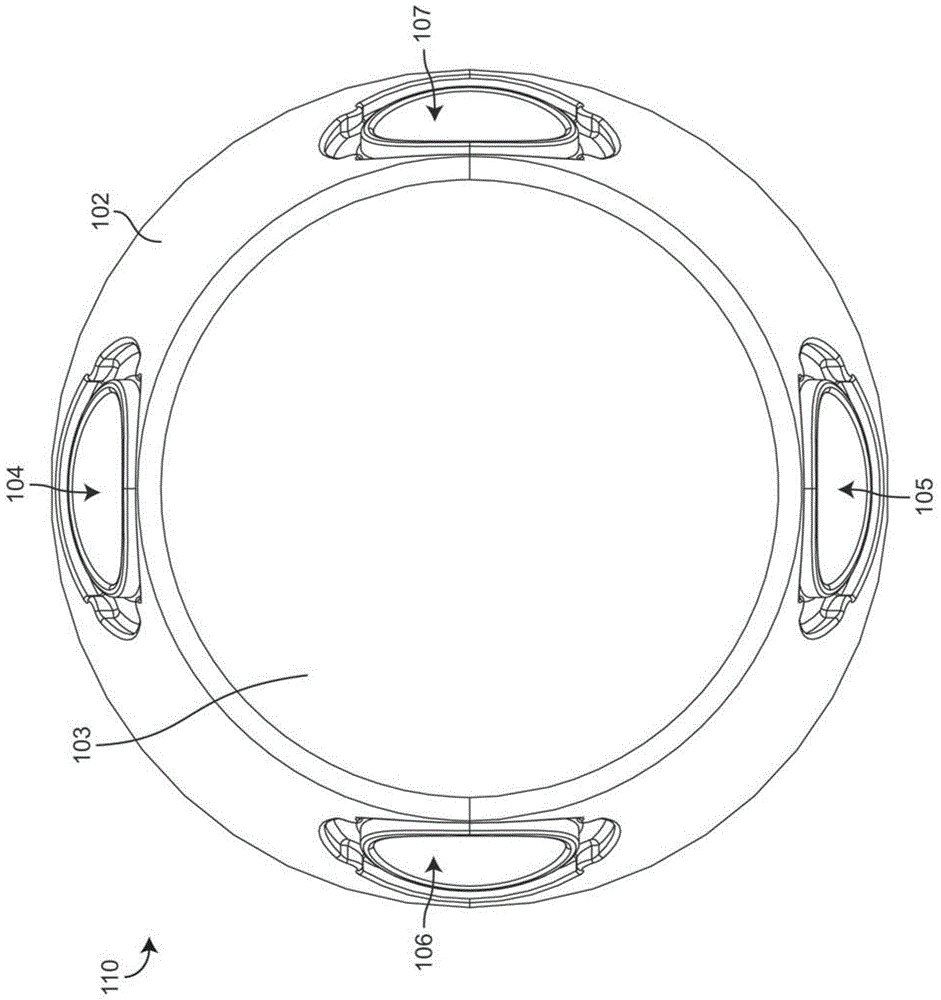

[0047] Referring generally to the drawings, a concentric diverter cartridge and components thereof are shown in accordance with exemplary embodiments. Before further discussing the details of the concentric diverter spool and / or its components, it should be noted that references in this specification to "front", "back", "rear", "top", "bottom", "upper", "lower" , "inner", "outer", "right" and "left" are used only to indicate the orientation of various elements in the drawings. These terms are not intended to limit the elements they describe, as various elements may have different orientations in various applications.

[0048] It should also be noted that in this specification, the term "coupled" means that two components are directly or indirectly connected to each other. Such connections may be substantially fixed or substantially movable, and / or such connections permit fluid flow, transmission of forces, stresses, torques, or other interactions between the connected compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com