Embroidery machine multi-turn wire guide

A multi-steering, embroidery machine technology, applied in the direction of embroidery machine, embroidery machine mechanism, textile and papermaking, etc., can solve the problems of low efficiency, time-consuming yarn, yarn winding, etc., and achieve the effect of improving the efficiency of thread guide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

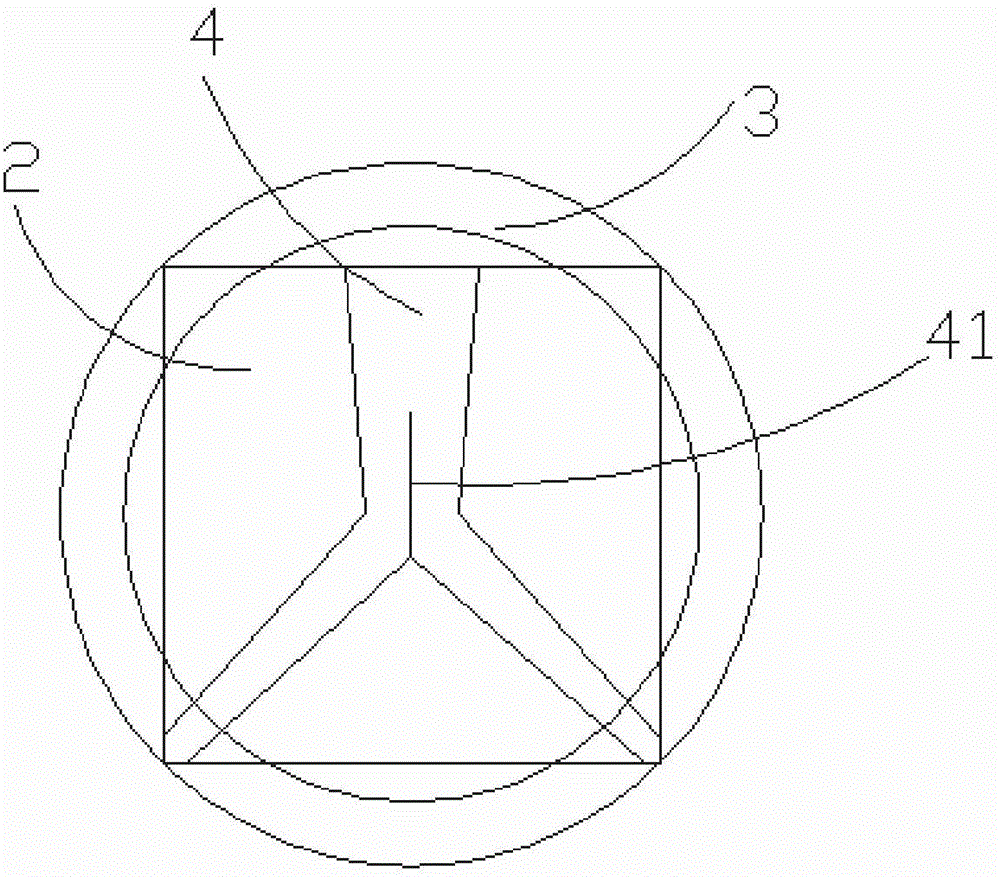

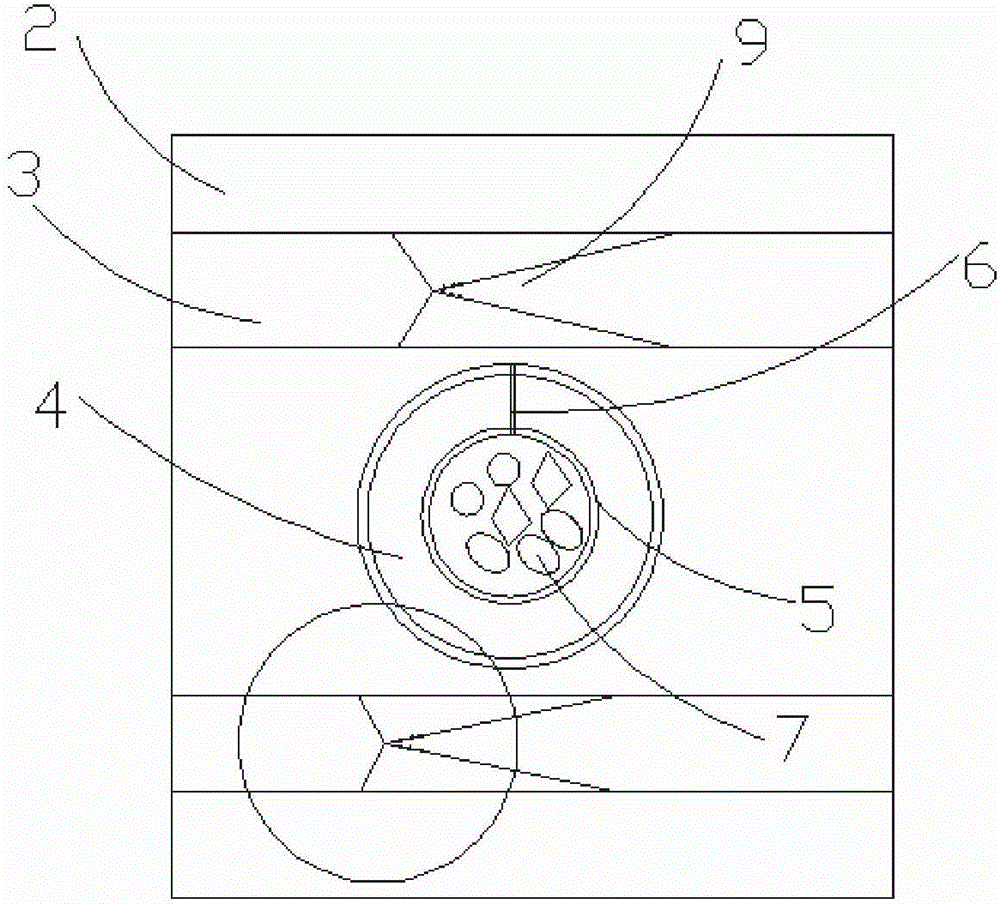

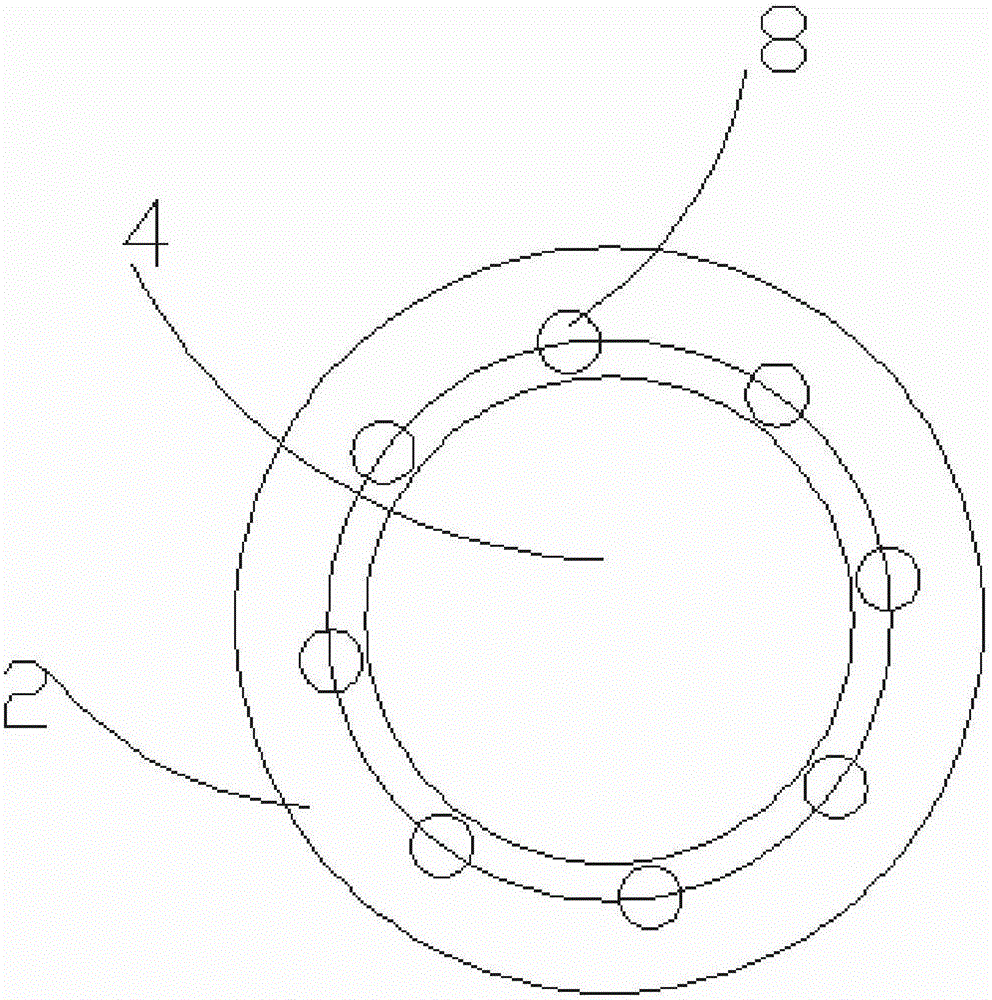

[0026] like Figure 1 to Figure 5 As shown, the present invention relates to a multi-turn wire guide for embroidery machines, which is characterized in that it includes a fixed end 1, and a guide wheel 2 is formed on the fixed end 1, and two guide grooves are formed on the outside of the guide wheel 2 3. A Y-shaped guide wire hole 4 is formed in the middle of the guide wire groove 3, and a thread shaker is provided at the inlet end of the guide wire hole 4; the thread shaker includes a traveler 5, and the traveler 5 The outside of the rim is fixed on the inlet port by an elastic steel wire 6, and a plurality of through-wire holes 7 with different aperture sizes are formed on the traveler 5, and the guide wire holes 4 are arranged sequentially from the diameter of the inlet port to the diameter of the outlet port. Narrowed down, a lubricating port is formed at the outlet port of the guide wire hole 4, and the lubricating port includes oil outlet holes 8 that are evenly distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com