Two-way Anchor Tubing Anchor for Heavy Oil Steam Flooding

A technology for steam flooding and tubing anchors, which is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc. It can solve the problems of the packer being difficult to unpack, and achieve reliable anchoring, high construction success rate, and flexible action. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

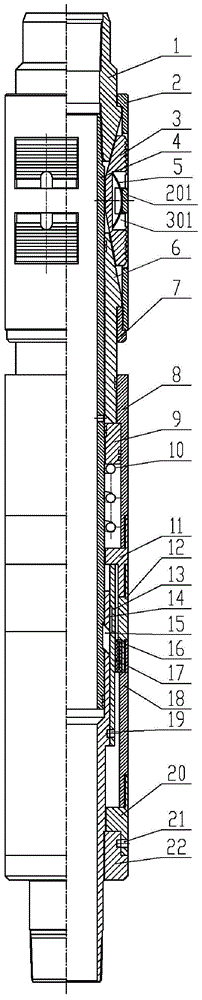

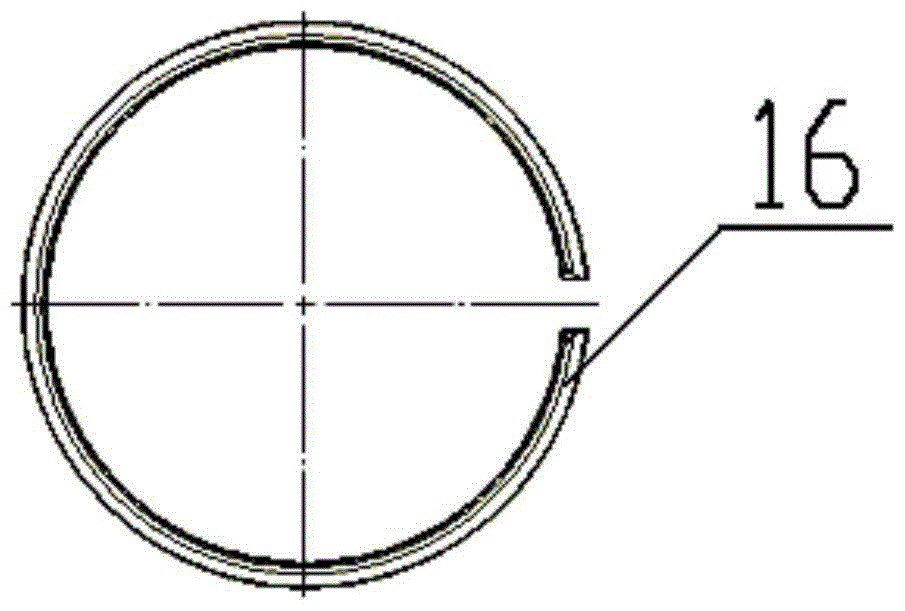

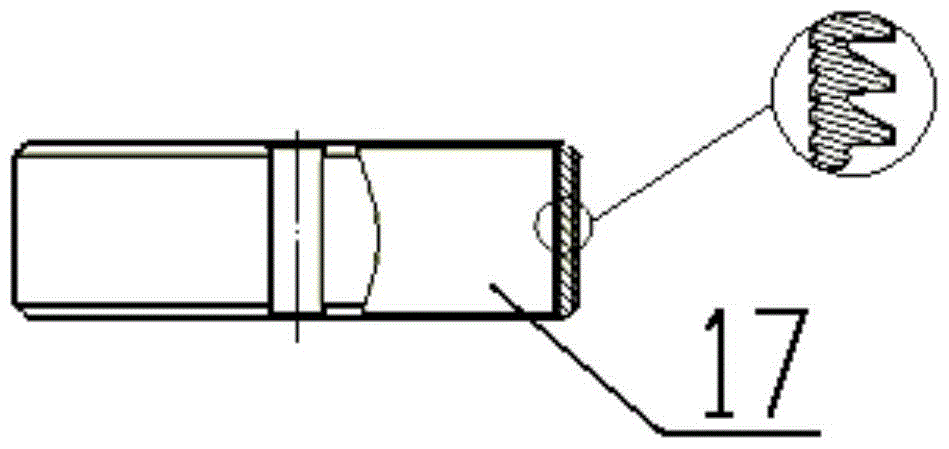

[0026] Such as Figure 1 to Figure 3 As shown, the present invention proposes a heavy oil steam flooding deblocking two-way anchoring tubing anchor, including slips 3, center pipe 4, lower cone 6, hydraulic cylinder 8 and fixed piston 9, and slips 3 are sleeved on Outside the upper end of the central tube 4, the lower cone 6 is slidably sleeved outside the central tube 4 and the upper part of the lower cone 6 abuts against the slips 3, and the slips 3 can follow the lower cone 6 along the axial direction of the central tube 4. Up or down to achieve anchoring or unsealing; the fixed piston 9 is fixedly sleeved in the middle of the central tube 4, and the liquid cylinder 8 is slidably sleeved outside the fixed piston 9, the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com