Container for isolating liquid prior to dispensing and method for dispensing liquid from container

A container, liquid technology, applied in the direction of flexible tubular containers, containers with multiple items, containers, etc., can solve problems such as changing the concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

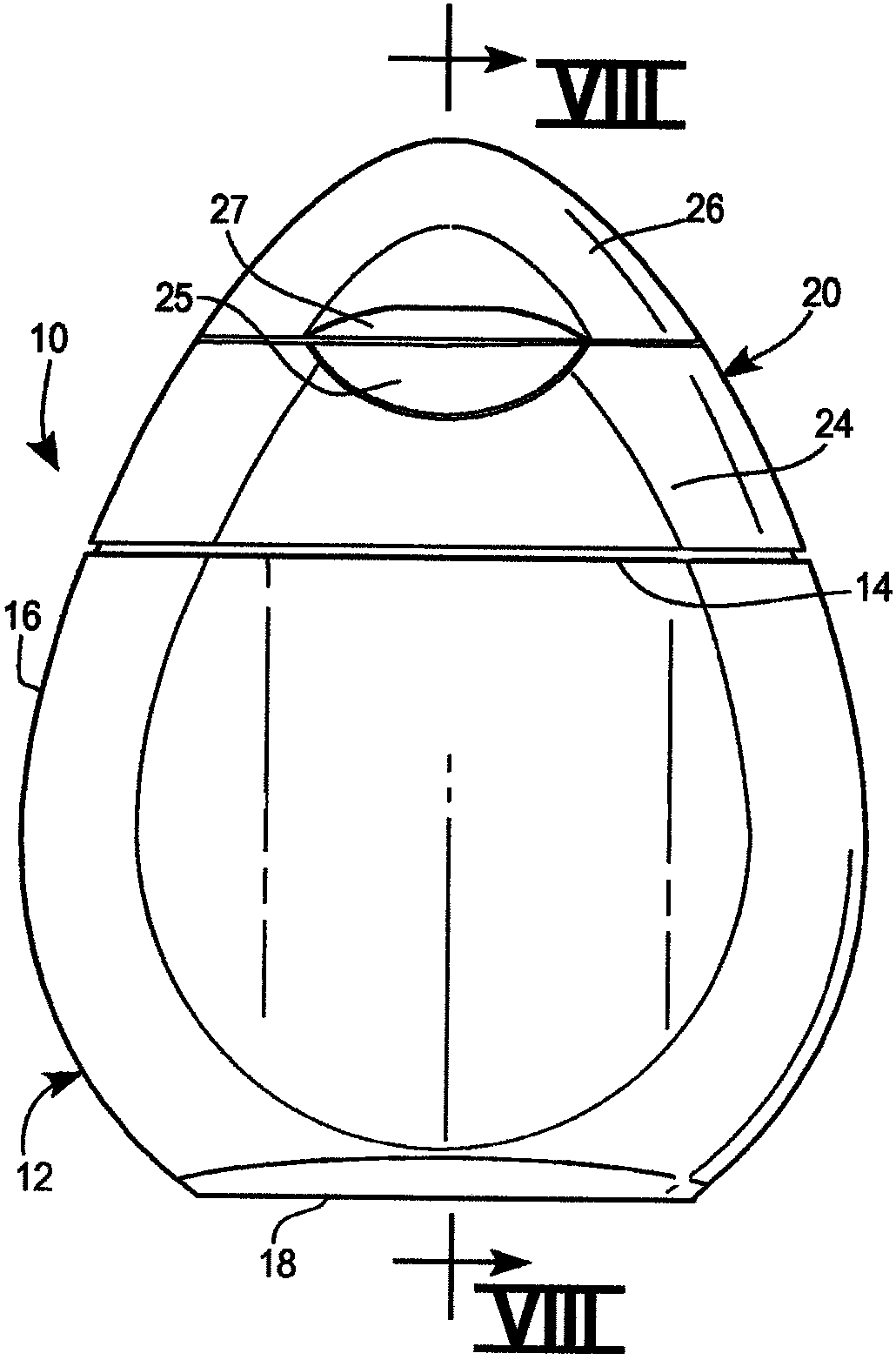

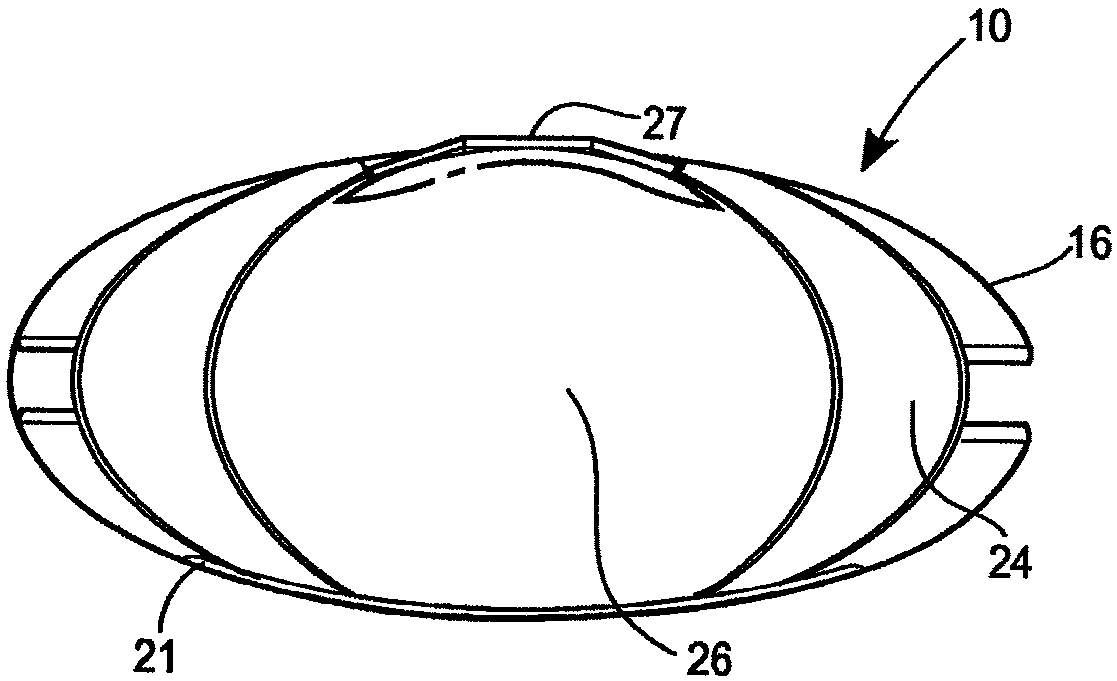

[0046] A container configured to isolate first and second fluids prior to dispensing and then combined during dispensing is provided, as well as a method of assembly and dispensing. The container is suitable for a variety of dispensing and the fluid may be a beverage ingredient or a beverage concentrate. Advantageously, the first and second fluids are kept separate prior to dispensing. It is also advantageous that during dispensing preferably only or substantially only the dispensed portions of the first and second fluids mix. That is, not all of the first and second fluids are mixing during a given dispensing cycle. The isolation of the dispensed portions of the first and second fluids prior to dispensing can limit or prevent the ability of one fluid to interact with the other. Avoiding such interactions can increase the shelf life of filled containers, for example, where fluid interactions can reduce shelf life. Such isolation can be achieved while still providing a conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com