Flotation liquid level image recognition equipment liquid surface defoaming device

A technology of image recognition and flotation liquid, applied in the direction of foam dispersion/prevention, etc., can solve the problem of not many theoretical methods, and achieve the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

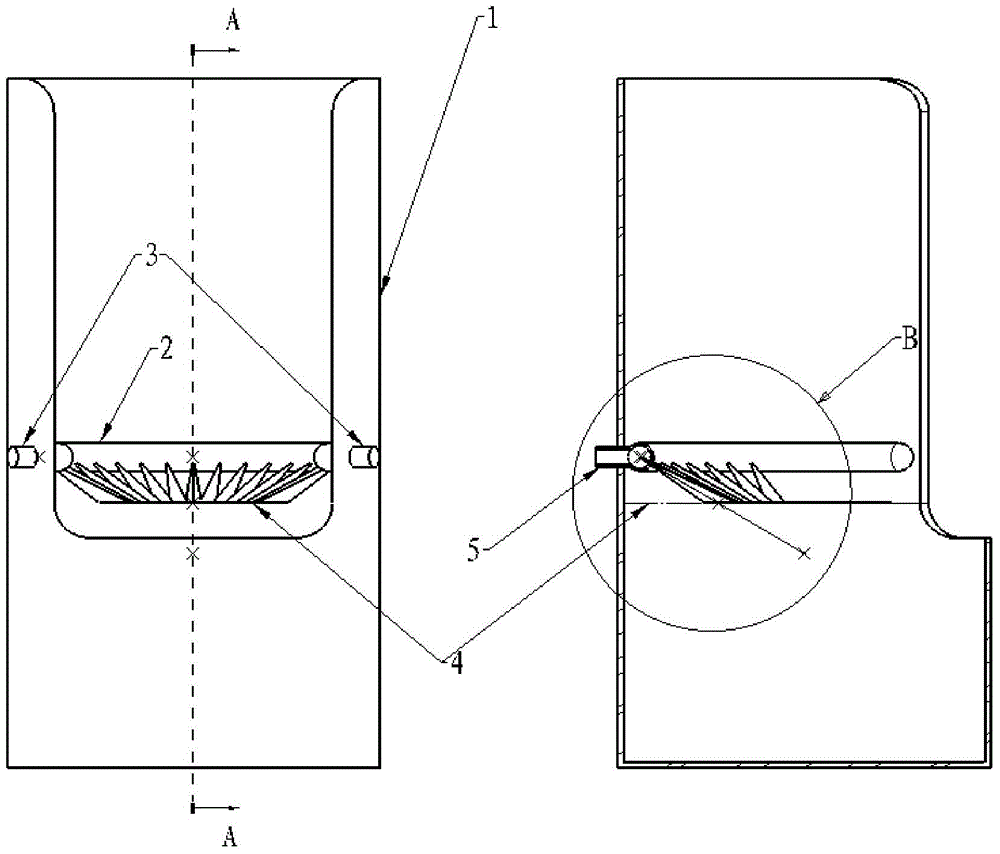

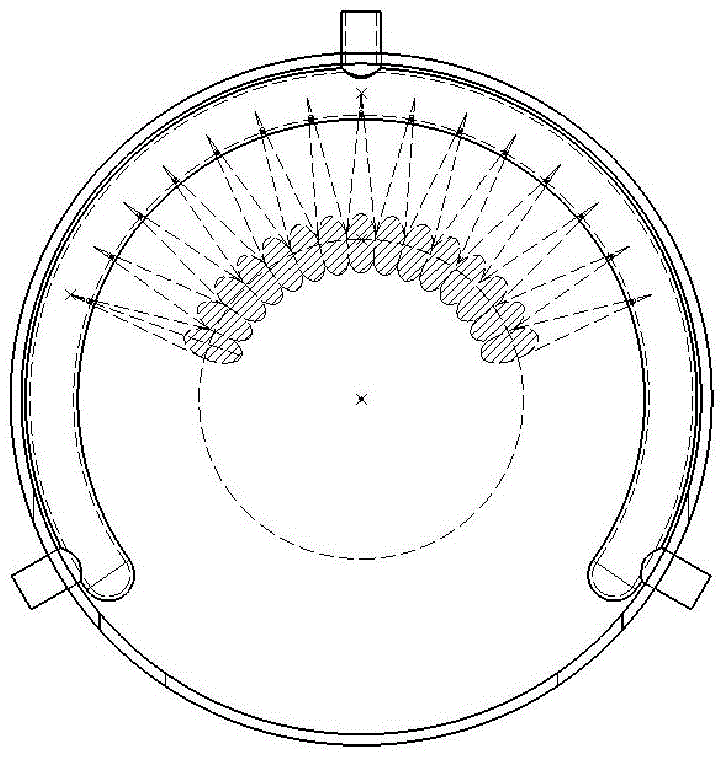

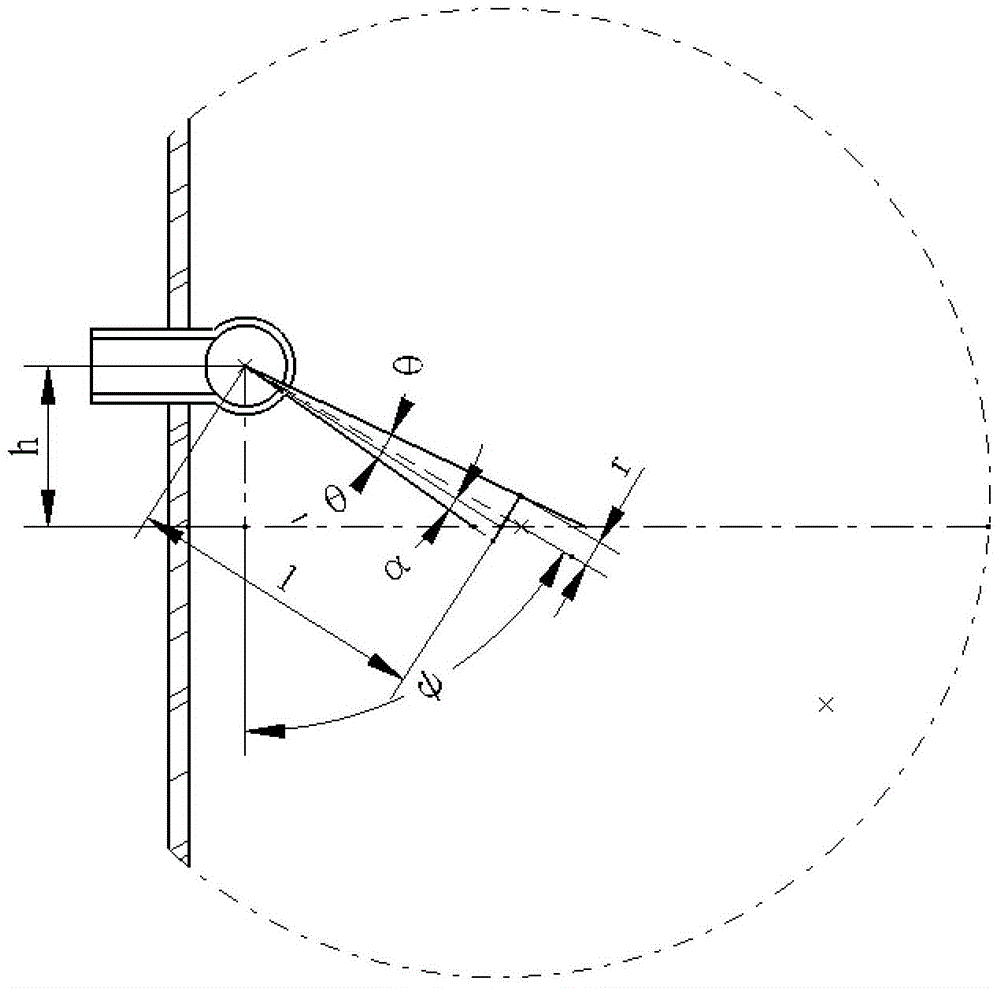

[0014] The present invention includes a device housing 1, an air guiding device 2, a fixing device 3, and an air inlet 5; the device housing 1 is placed at the position of the liquid level to be measured to ensure that the internal and external liquid levels of the device are connected, and the gas guiding device 2 is located in the device housing 1 inside, it is used to blow the compressed air introduced from the air inlet 5 to the liquid surface through the angle and intensity determined by the specific parameters of the device to remove foam, and the fixing device 3 fixes the air guide device 2 inside the device housing 1.

[0015] During the working process of the device, the air compressor inputs air into the air inlet, the volume of air output by the compressor per unit time is V, and the initial velocity obtained by the air is v 0 , the cross-sectional area of the intake duct is S 0 , the air enters the pipeline and flows out from n air outlets, blowing the bubbles fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com