A wet electrostatic precipitator nozzle online clearing device

A wet electrostatic precipitator and nozzle technology, applied in electrostatic separation, external electrostatic separator, etc., can solve problems such as low efficiency, affecting production efficiency, and unsatisfactory cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

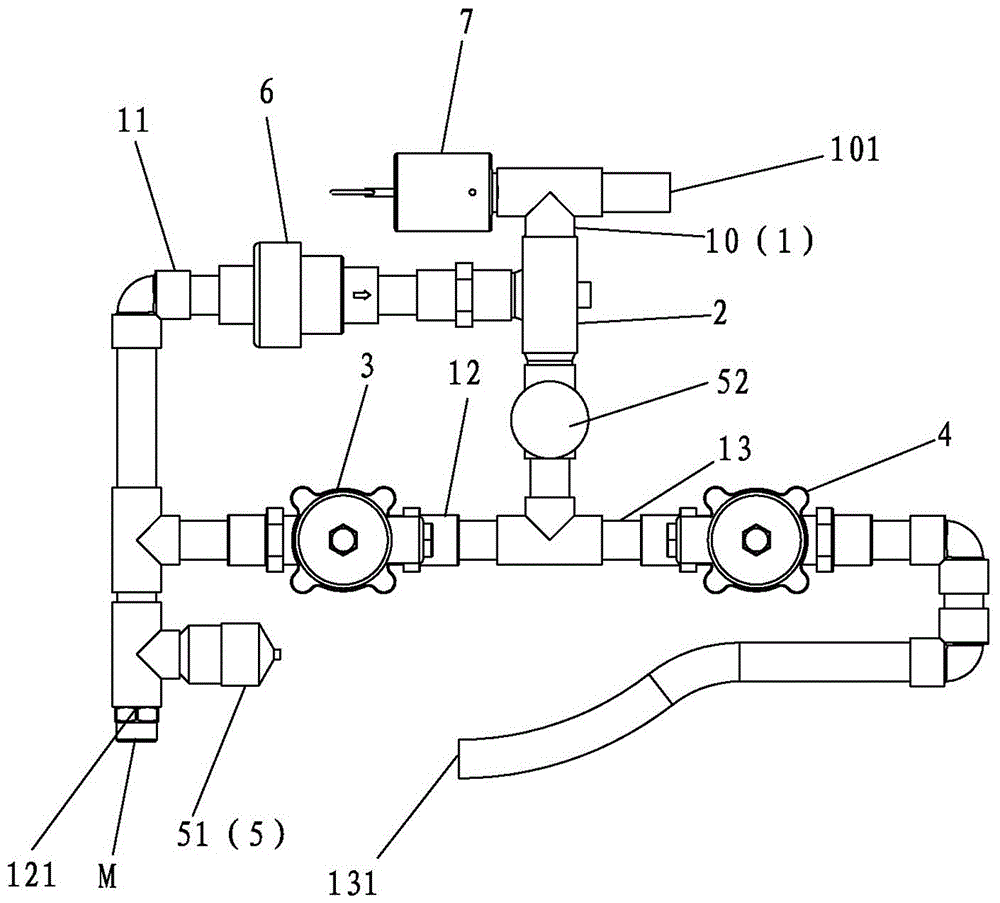

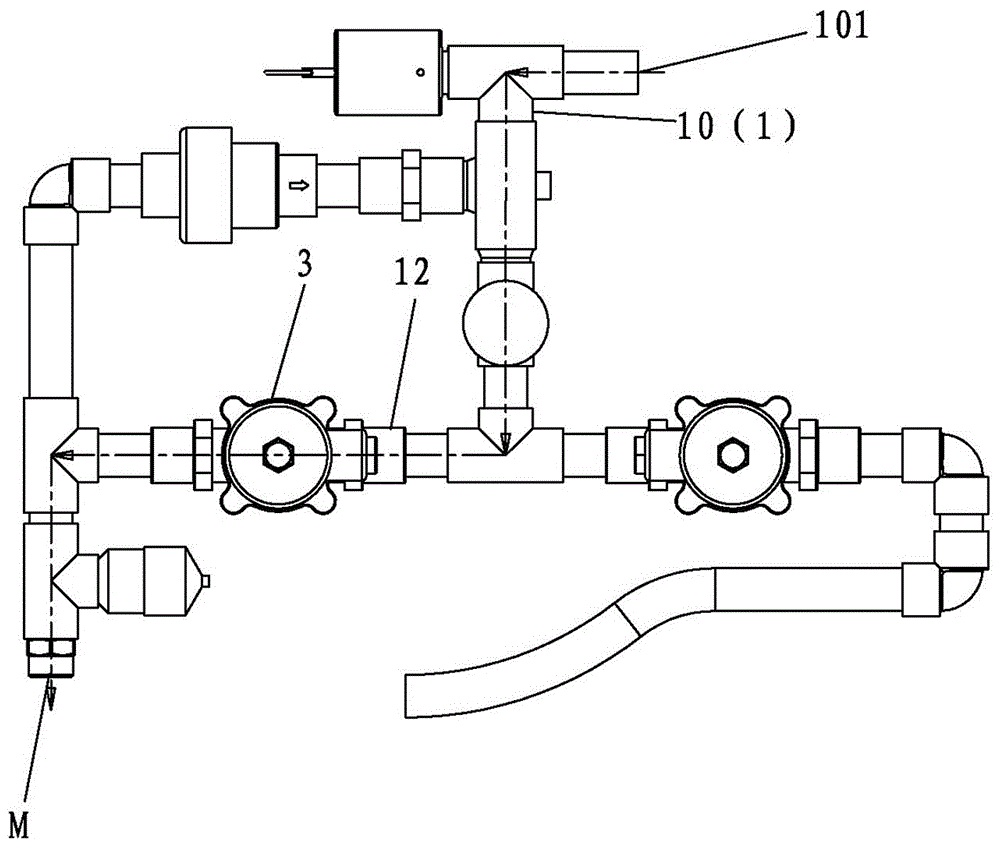

[0029] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

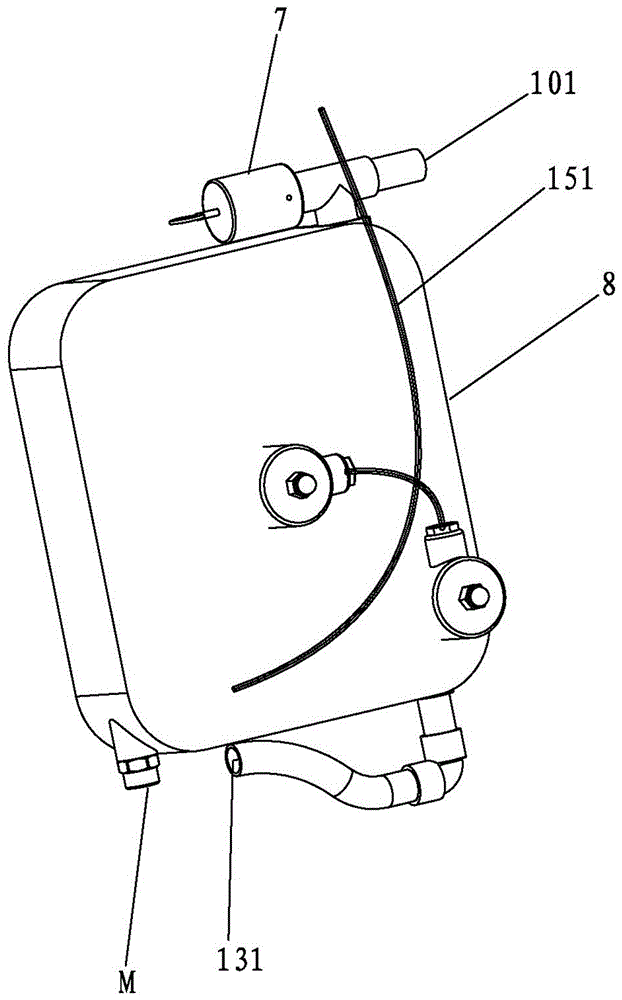

[0030] This case involves an online plugging device for wet electrostatic precipitator nozzles, such as Figure 1-2 As shown, it mainly includes a pipeline 1 , a venturi tube 2 (ejector) arranged on the pipeline 1 , a first valve part 3 and a second valve part 4 .

[0031] The pipeline 1 has a main path 10 and three branch paths. One end of the main road 10 constitutes a pipe inlet 101 . The three branch roads are all connected to the main road 10 and are respectively the first branch road 11 , the second branch road 12 and the third branch road 13 . The free ends of the first branch 11 and the second branch 12 merge, and the free ends of the pipe extending from the junction constitute a nozzle opening 121 for the nozzle M to be installed. The free end of the third branch 13 is a plugging outlet 131 .

[0032] The Venturi tube 2 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com