Peripheral positioning method of automotive glass inserts

A technology of automobile glass and positioning method, which can be applied to household components, applications, instruments, etc., and can solve problems such as complex fitting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0024] A peripheral positioning design method for an automotive glass insert, the steps comprising:

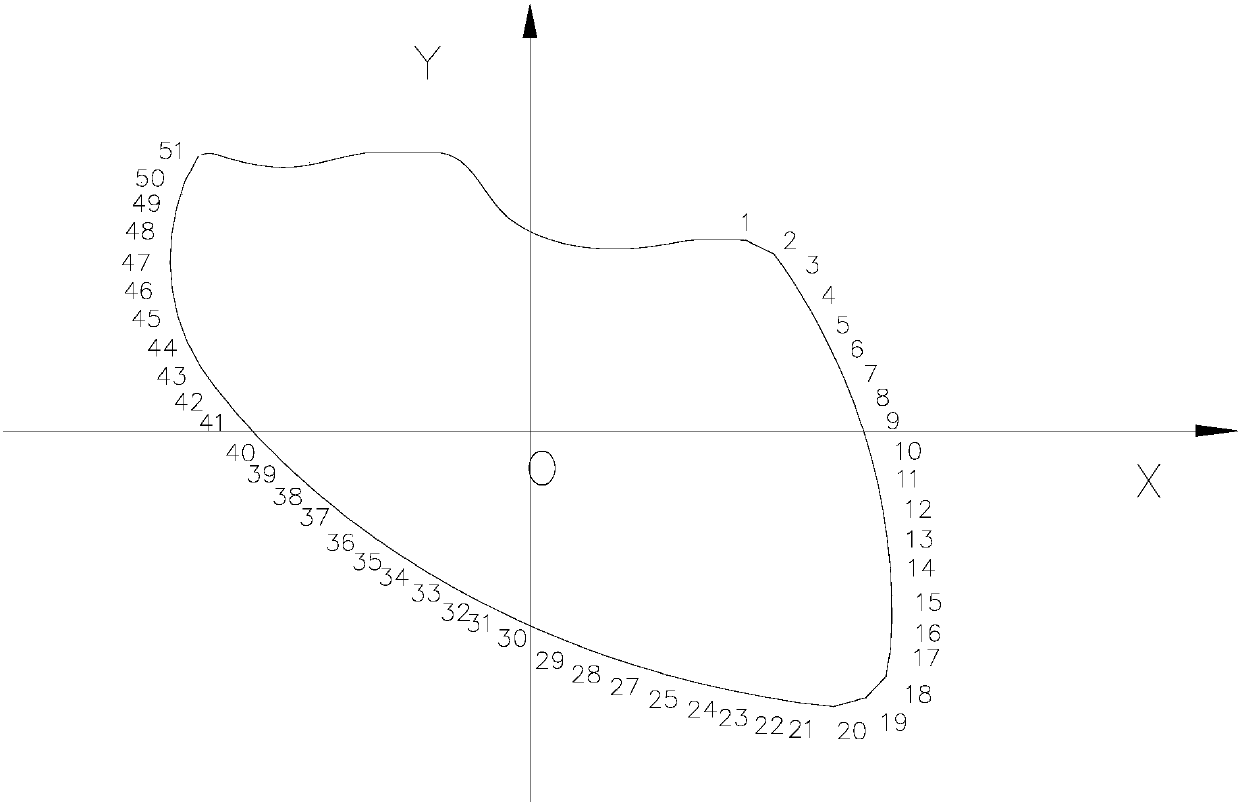

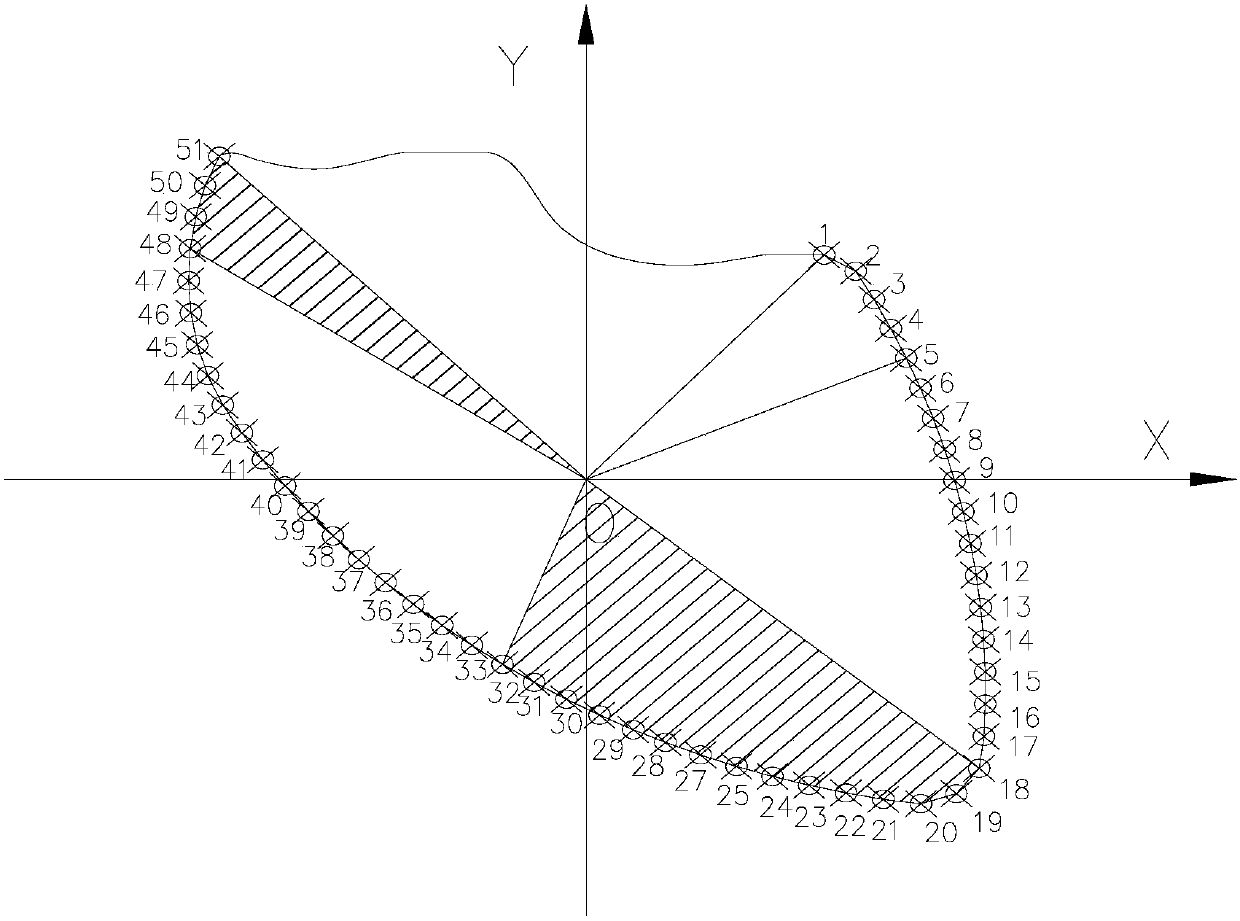

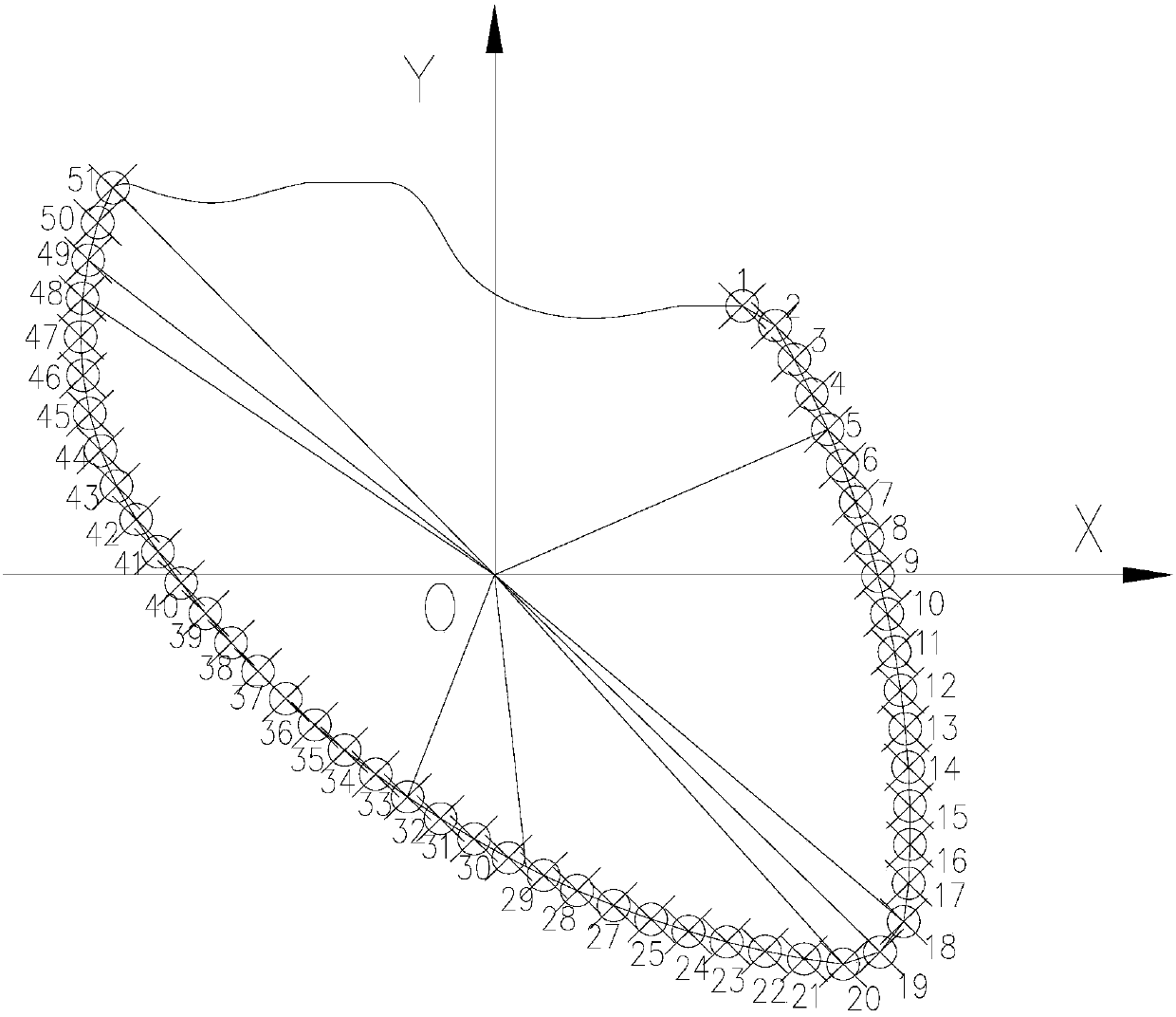

[0025] Step 1, taking the outline centroid O of the obtained automobile glass as the origin to establish a coordinate system, determine the peripheral curve of the automobile glass, and measure the length of the peripheral curve of the automobile glass;

[0026] Step 2: Based on the length of the peripheral curve of the automobile glass, divide the peripheral curve of the automobile glass into N equal segments to obtain (N+1) segmentation points (X, Y), and obtain (N+1) respectively The normal vector a(X,Y) of the split point;

[0027] In this implementation, the peripheral curve of the automobile glass is divided into 50 equal segments to obtain 51 segmentation points, each of which is shown in the coordina...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap