Transformation and use method for cleaning and consigning trolleys for various V-shaped positioning axle housings

A multi-variety, axle housing technology, applied in cleaning methods and appliances, chemical instruments and methods, transportation and packaging, etc., can solve the problems of heavy workload, easy damage to the car body, and unacceptable problems, so as to avoid forced demolition and rewelding , The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0068] It has been mentioned before that the present invention is a technical scheme of a “cleaning consignment trolley” for “V-shaped positioning” axle housing parts” and its positioning and limit assembly “processing and preparation method” when researching a kind of cooperation research. A kind of " conversion method of use ", for this reason, for the convenience of understanding above-mentioned content of the present invention, below, at first introduce the structural representation and configuration situation of used " cleaning consignment trolley ":

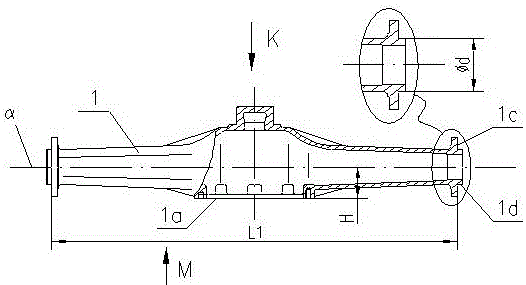

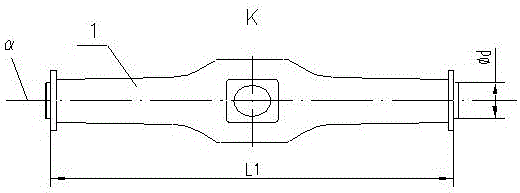

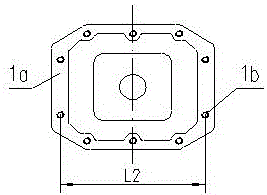

[0069] Depend on Figure 7 to Figure 9 and combine Figure 1 to Figure 3 and Figure 10 to Figure 21It is known that a cleaning cons...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap