Measurement calibration method, device and angle adjustment mechanism based on angle adjustment mechanism

An angle adjustment and angle technology, which is applied in measuring devices, optical devices, instruments, etc., can solve the problem of inability to effectively realize the measurement and calibration of two servo angular displacement stages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

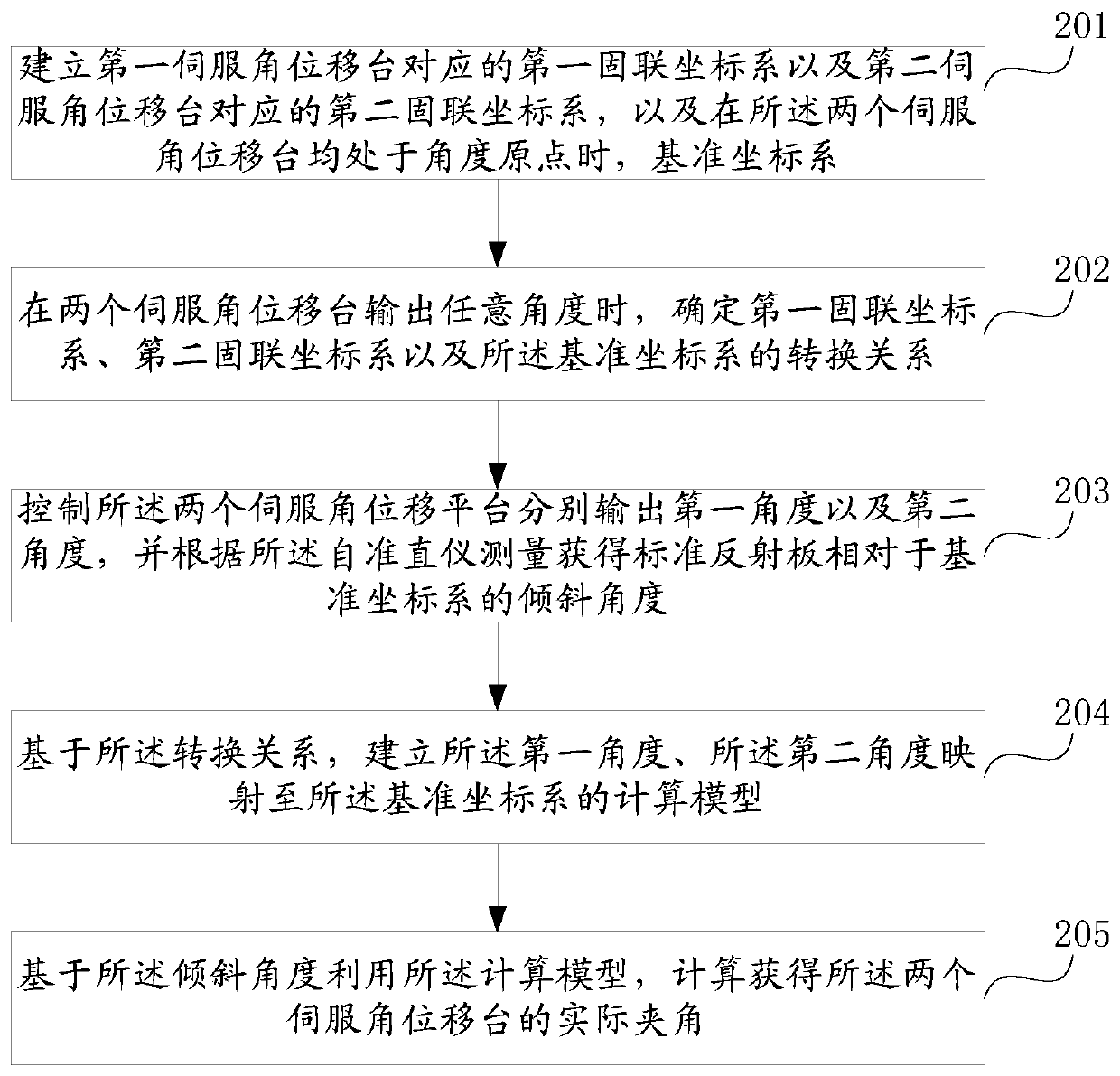

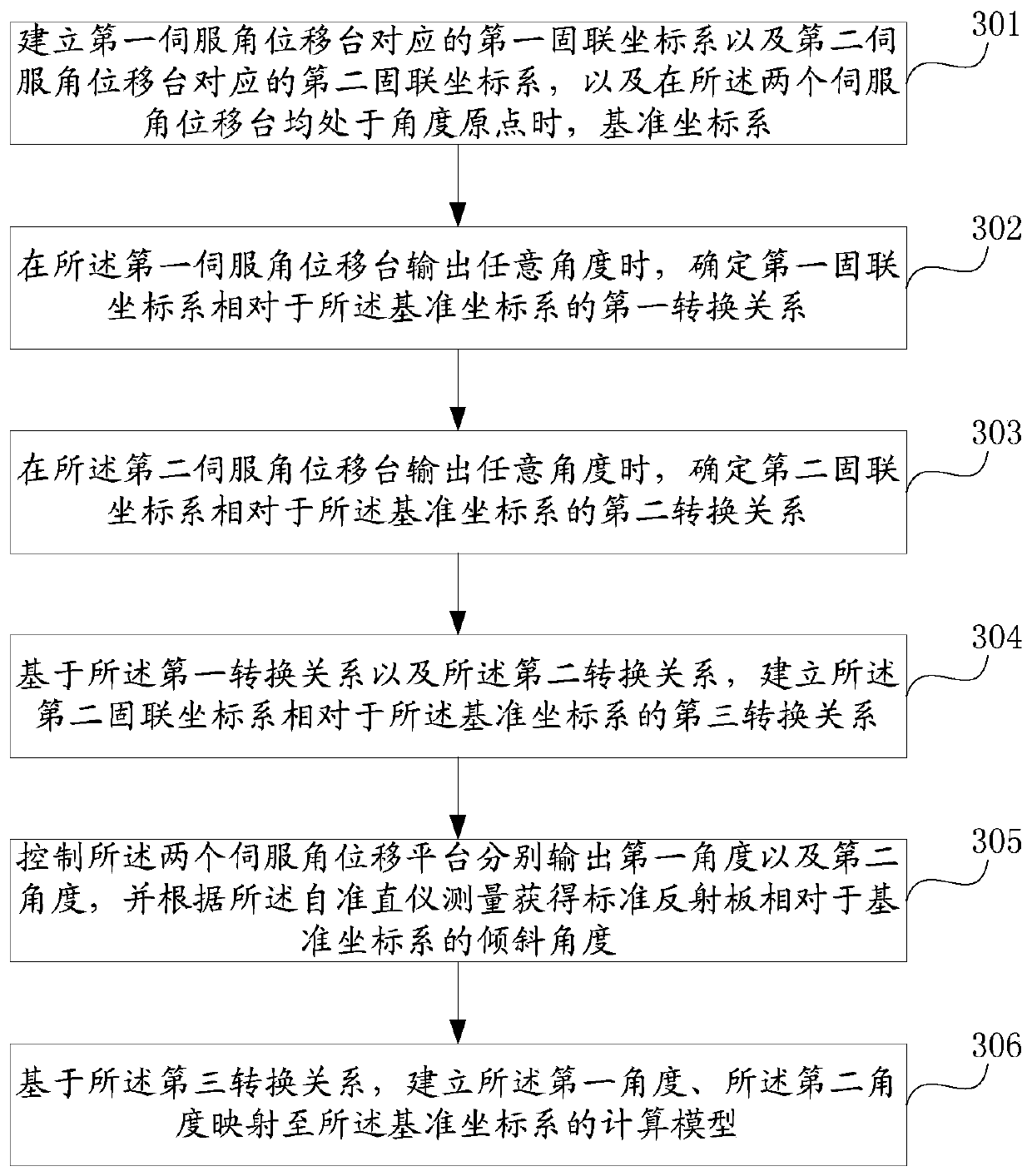

[0065] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

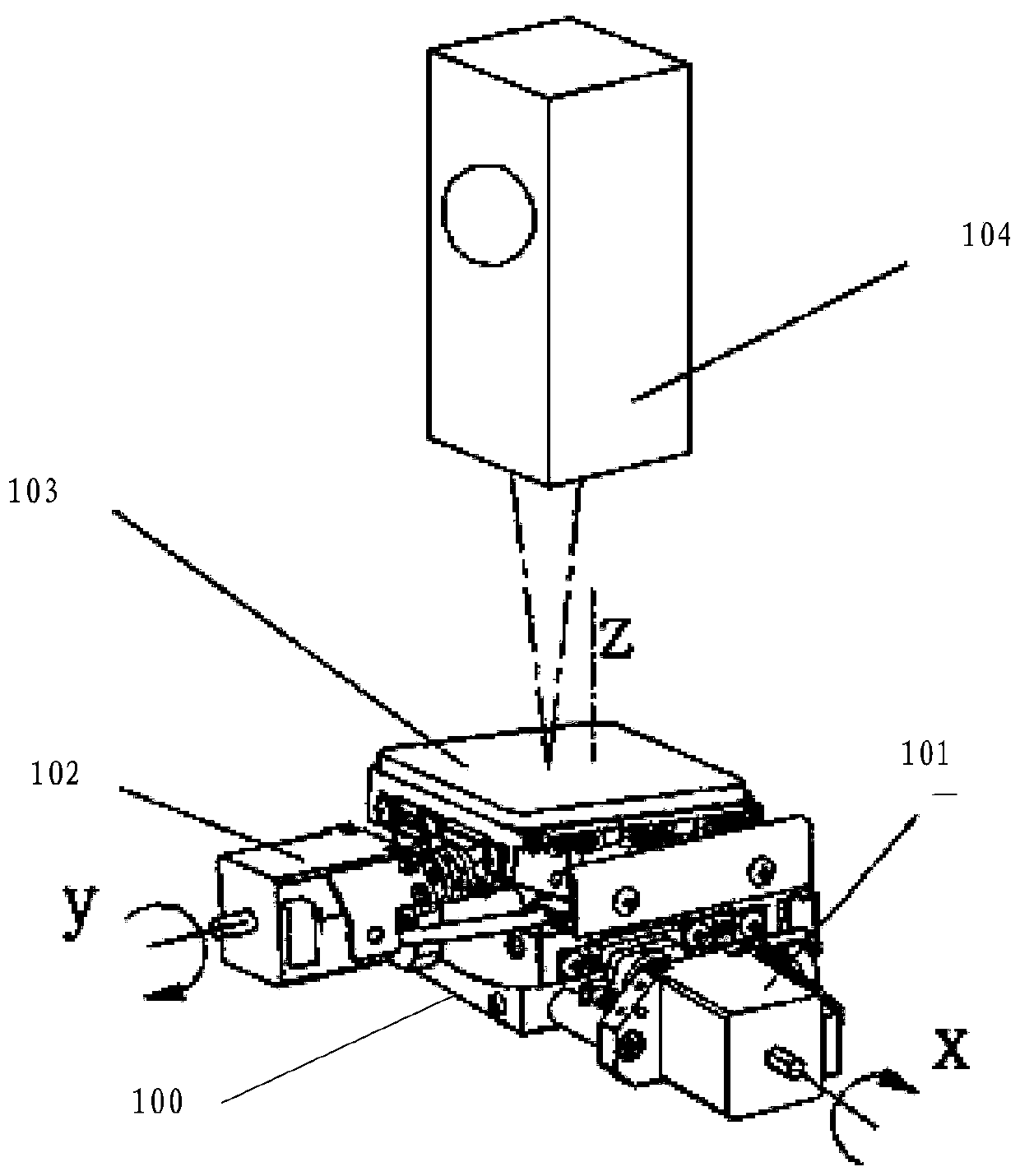

[0066] The embodiment of the present invention is mainly used in the scene of automatic adjustment of the spatial angle in the data field, mainly by actually determining the difference between the actual angle and the theoretical angle of the two servo angular displacement stages, and the linkage time of the two servo angular displacement stages through the angle difference. The actual linkage angle is compensated to ensure the accuracy of the control angle.

[0067] In the prior art, the CNC system needs to adjust the angle of the workpiece when performing processing operations. Usually, the angle adjustment of the workpiece is adjusted by the linkage of two servo angul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com