A pressing mechanism for flat labeling of packaging boxes

A compression mechanism and packaging box technology, applied in labeling machines, packaging, labeling, etc., can solve the problems of reducing the production efficiency of packaging boxes and the speed of labeling, etc., achieve simple structure, ensure labeling requirements, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

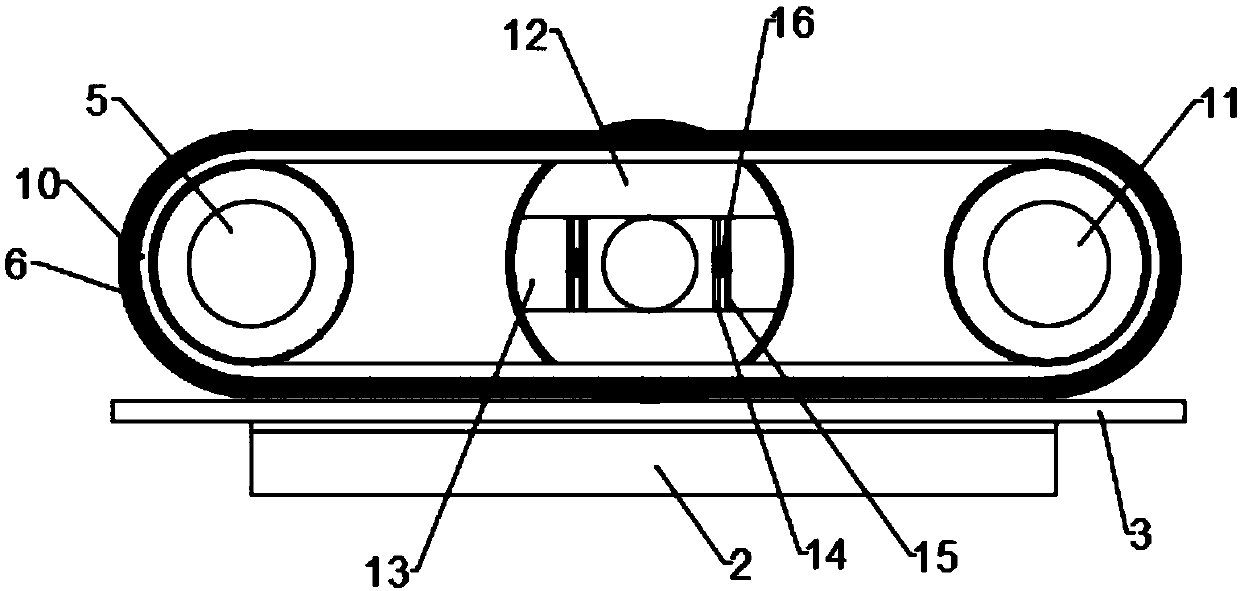

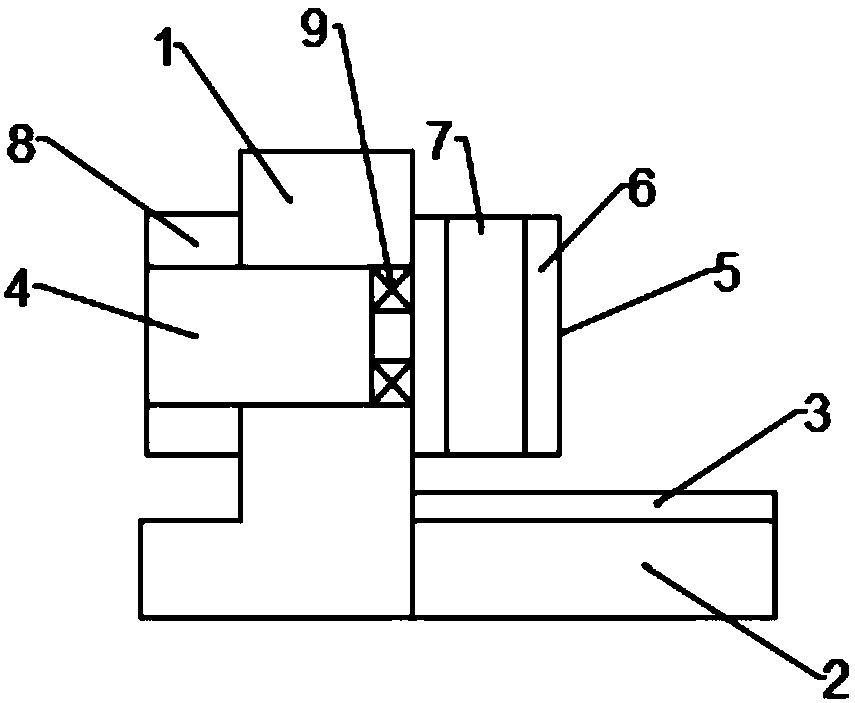

[0018] Such as figure 1 and figure 2 As shown, the present invention provides a pressing mechanism for flat labeling of packaging boxes, including a fixed seat 1, a drive motor 4 is installed on the left end of the fixed seat 1, and a transverse drive mechanism 8 is installed on the drive motor 4 , the driving motor 4 is connected with a driving wheel 5, a driven wheel 11 is installed on the right end of the fixed seat 1, two inner belts 10 are installed on the driving wheel 5 and the driven wheel 11, and the inner belt 10 passes through the gear Engage the driving wheel 5 and the driven wheel 11, the inner belt 10 is covered with a sponge wheel 6, an intermediate gap 7 is provided between the two inner belts 10, and a sticker is provided between the driving wheel 5 and the driven wheel 11. Labeling wheel 12, the two sides of the labeling wheel 12 are embedded with stickers 13, the stickers 13 are connected to the inside of the labeling wheel 12 through spring sleeves 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com