Electric control valves for coolant compressors

A control valve, electrical control technology, applied in refrigerators, refrigeration components, mechanical equipment, etc., can solve the problems of material fatigue, aging, and inability to ensure that the bellows filled with gas mixtures are kept tight, etc., to achieve cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

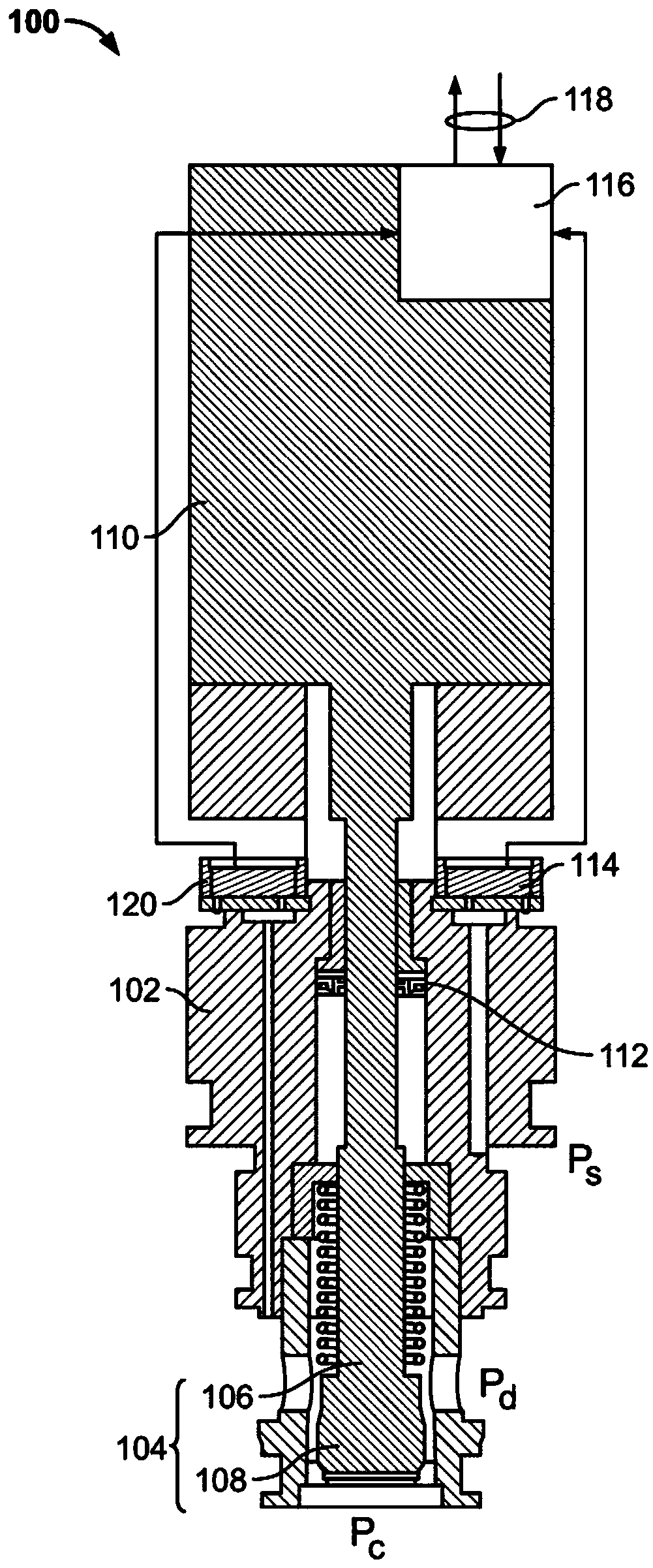

[0035] After this, refer to figure 1 , first the general inventive principle of the electric control valve 100, in particular for a coolant compressor, for controlling the coolant from the high pressure area into the crankcase-chamber-pressure area will be described in more detail flow.

[0036] figure 1 A control valve according to the present invention for a coolant compressor of a first embodiment is shown; embodiments of individual components of the control valve and improvements of the control valve are described in more detail in connection with the description. A control valve 100 controls the flow of coolant from the high pressure area of a coolant compressor (not shown) into the crankcase-chamber-pressure area. For this purpose, the control valve 100 comprises a valve housing 102 with a connector Pd for connection to the high-pressure area of the coolant compressor, with a connector Pd for connection to the crankcase-chamber-pressure area of the coolant compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com