Pneumatic tire

A pneumatic tire and bead technology, applied to the reinforcement layer of pneumatic tires, motorcycle tires, tire parts, etc., can solve the problems of inability to obtain lateral force and the impact of ground contact area, so as not to damage high-speed stability and realize lateral The effect of increasing force and lateral force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

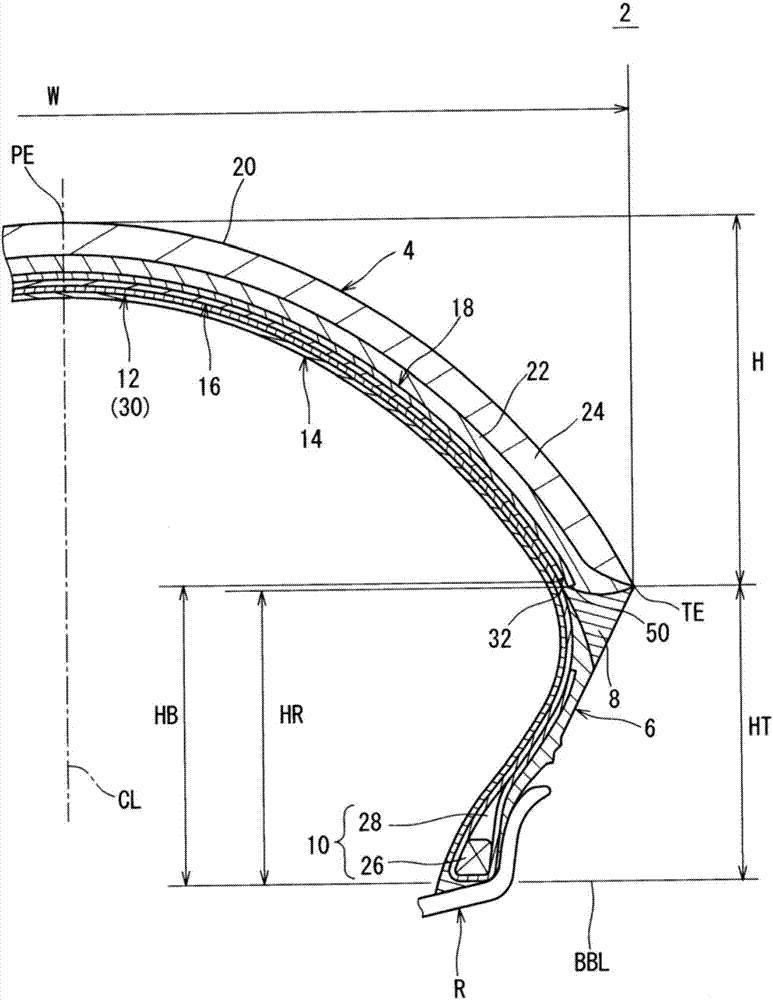

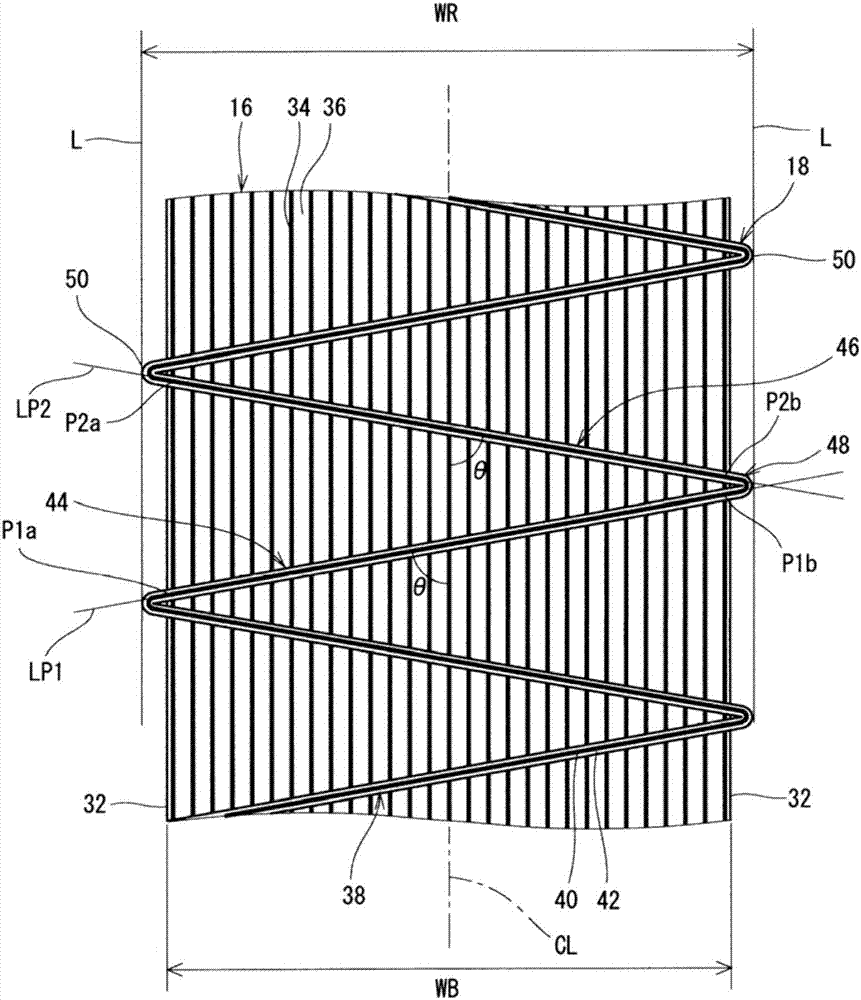

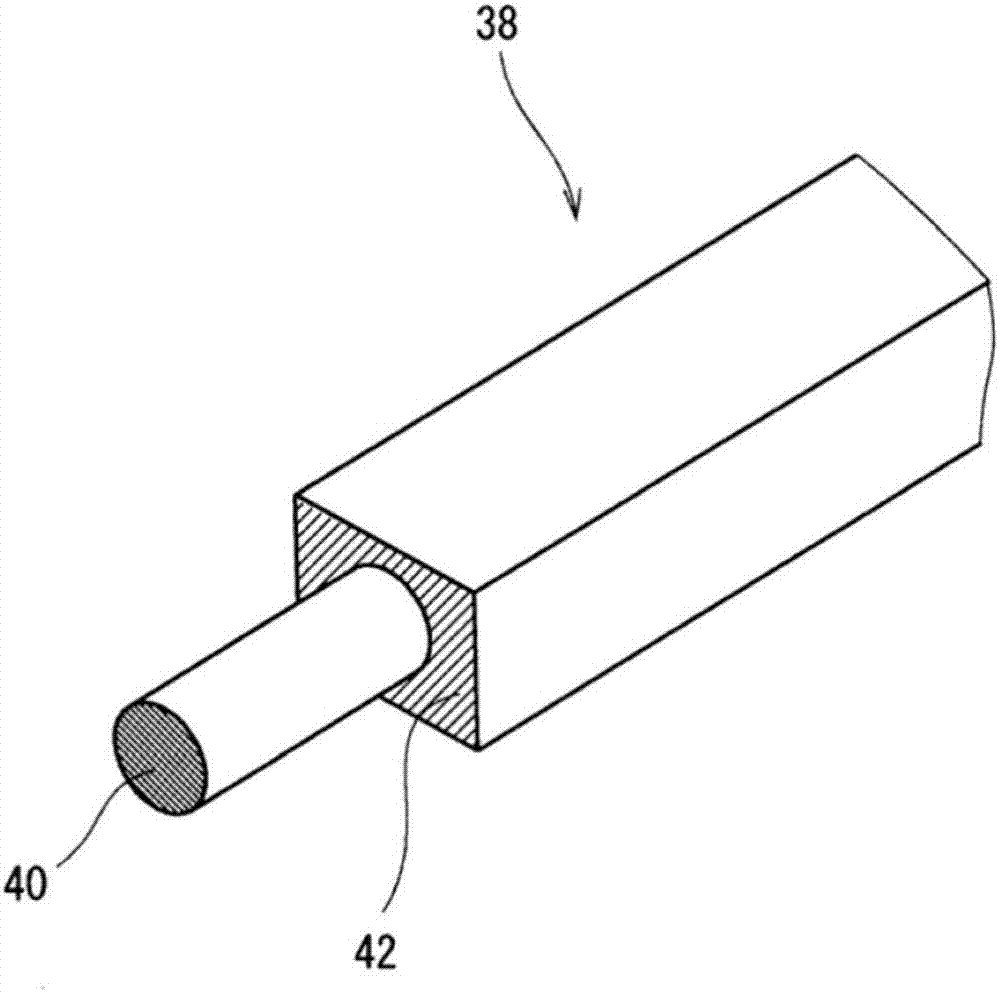

[0108] made figure 1 tires shown. The tire size is 190 / 55R17. In this Example 1, a figure 2 Reinforcing layers of the composition shown. In this Example 1, since the reinforcing layer is constituted by a strip wound once in the circumferential direction, this is indicated as "1" in the column of "Number of Laminations" in Table 1 below.

[0109] In this Example 1, the inclination angle θ of the reinforcing cord is set to 70°, and is set to be the same whether it is on the equatorial plane or on the shoulder portion. " and the column of "inclination angle θs" is represented by "70".

[0110] In this Example 1, a cord (composition = 880 dtex / 2) composed of aramid fiber was used as a reinforcing cord.

Embodiment 2

[0118] In addition to being used as a reinforcement layer with Figure 5 A reinforcing layer having the configuration shown was used, and the tires of Example 2 were obtained except that the inclination angle θc and the inclination angle θs were the same as those in Example 1 except as shown in Table 1 below.

Embodiment 3

[0120] In addition to being used as a reinforcement layer with Image 6 A reinforcing layer having the configuration shown was used, and the tire of Example 3 was obtained except that the inclination angle θc and the inclination angle θs were the same as in Example 1 except that they were as shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com