Pulling-out tool

A tool and component technology, applied in the field of pulling tools, can solve problems such as the difficulty in aligning the pulling hook and the pulling hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

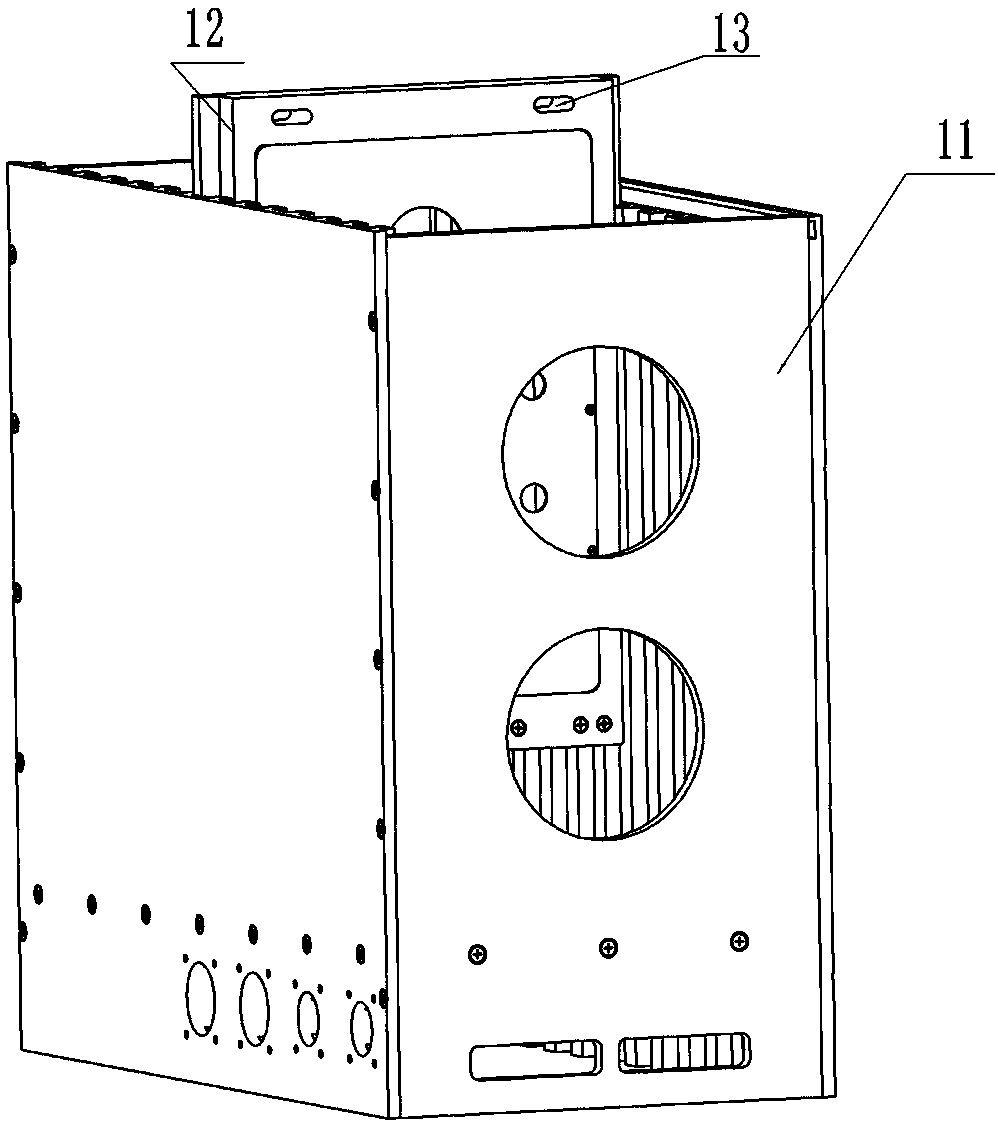

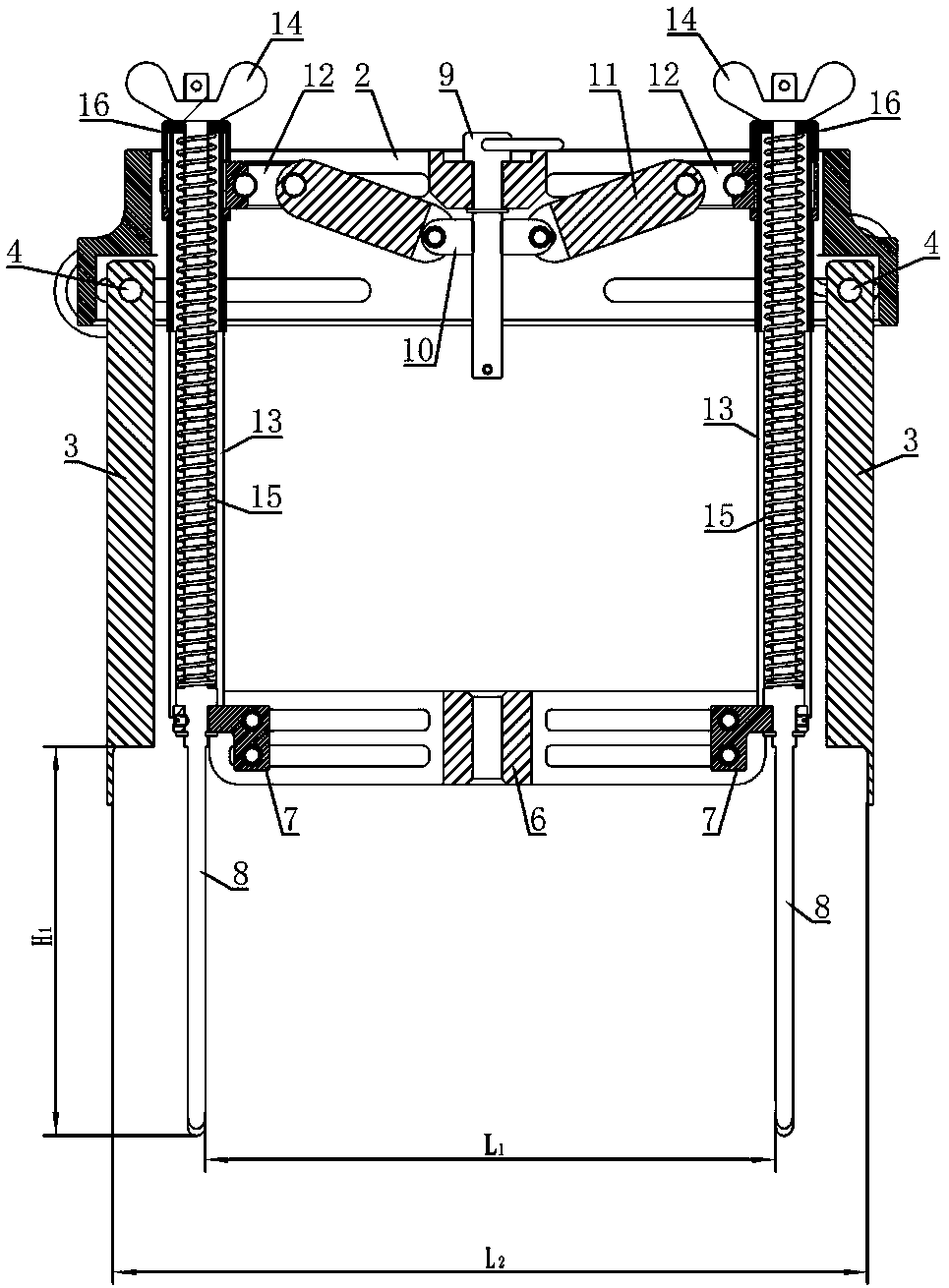

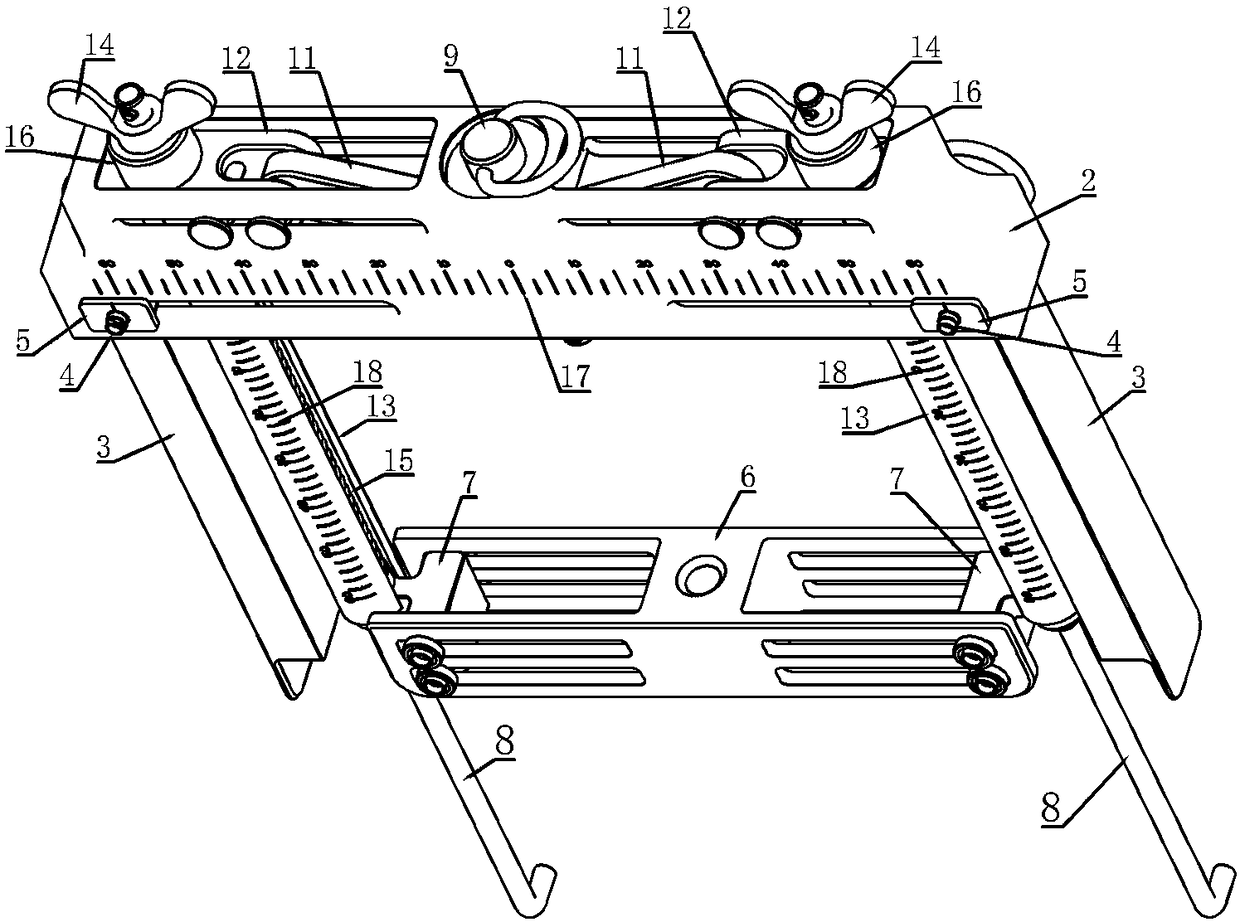

[0033] Embodiment of the pulling tool in the present invention: the pulling tool is an industrial-grade adjustable pulling tool suitable for pulling out a functional module from a chassis, such as figure 2 with image 3 As shown, the pulling tool is mainly composed of a support frame, a pulling part, a distance adjustment mechanism, and a depth adjustment mechanism. Lifting holes with a wide spacing; under the adjustment of the depth adjustment mechanism, it can be adapted to the lifting holes of different depths in the box on the functional module.

[0034] The support frame is mainly composed of a support 2 and legs 3 symmetrically arranged on the left and right sides thereof.

[0035] Such as Figure 4 As shown, the support 2 is a left-right symmetrical box structure with respect to a reference elevation extending forward and backward. The direction and the thickness direction are in the up-down direction. The support 2 is divided into an upper box body 201 and a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com