Apparatus for injection moulding of plastic materials

A plastic material and injection molding technology, applied in the field of injection molding (moulding) equipment, can solve the problem that the operator has no advantage in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

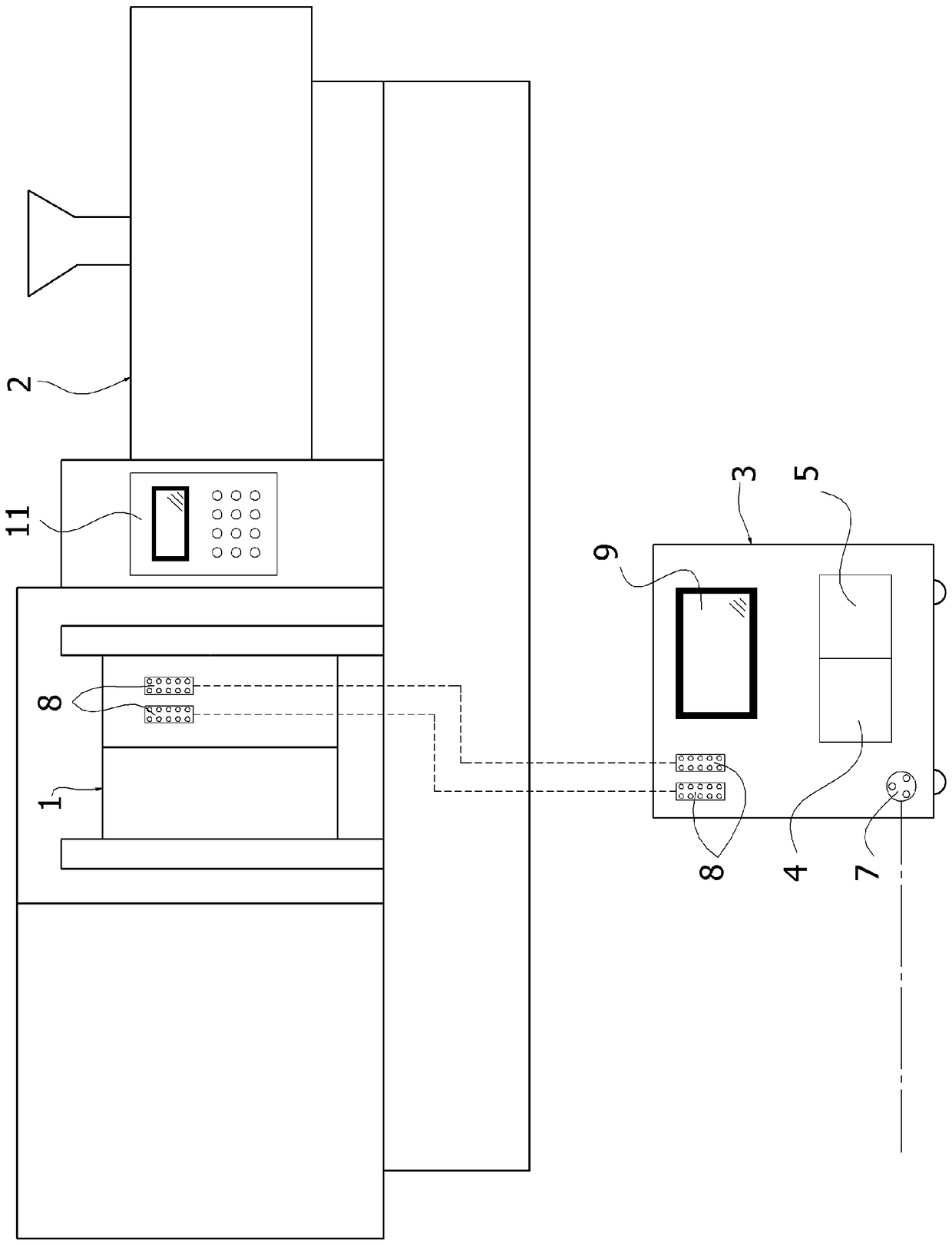

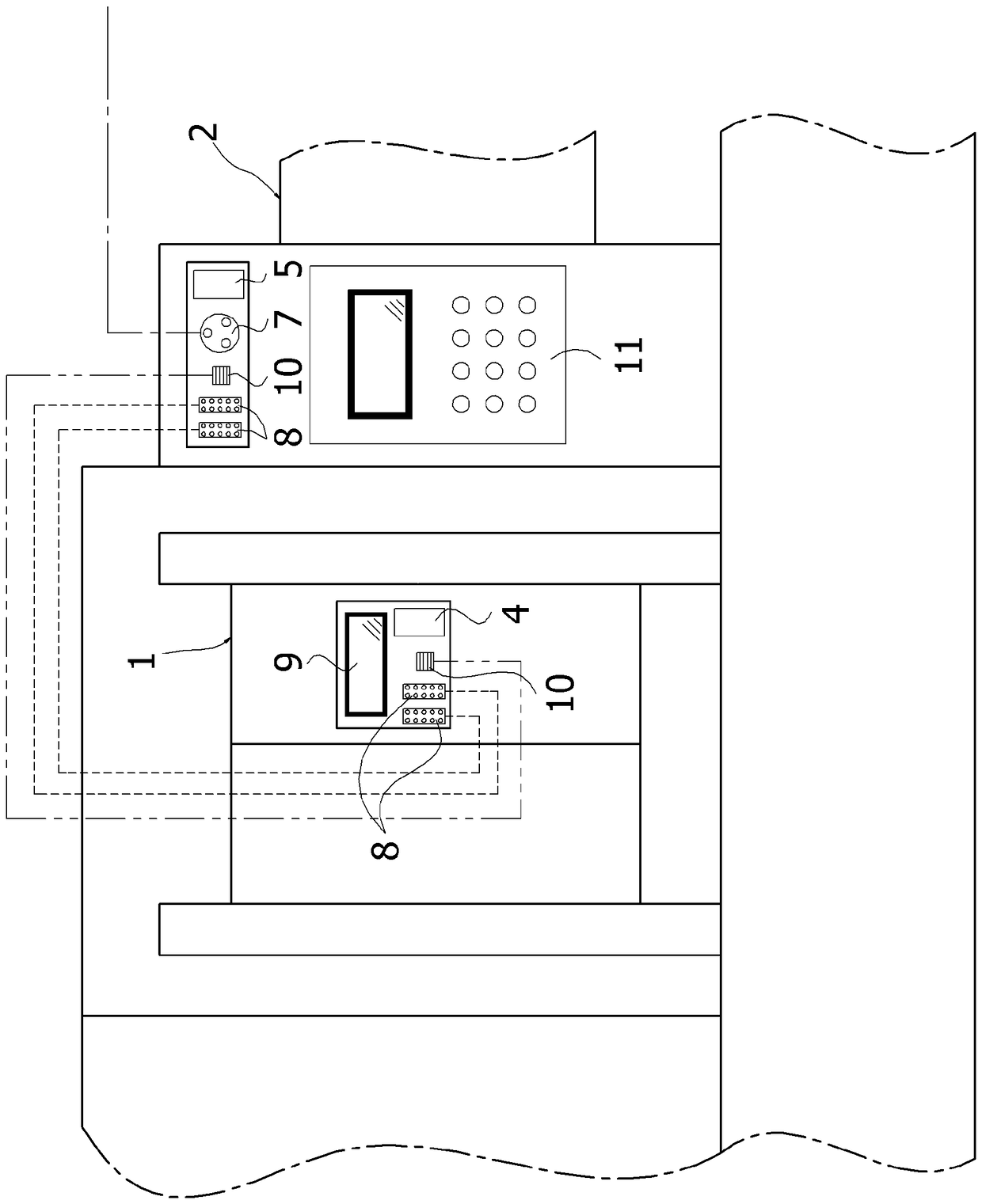

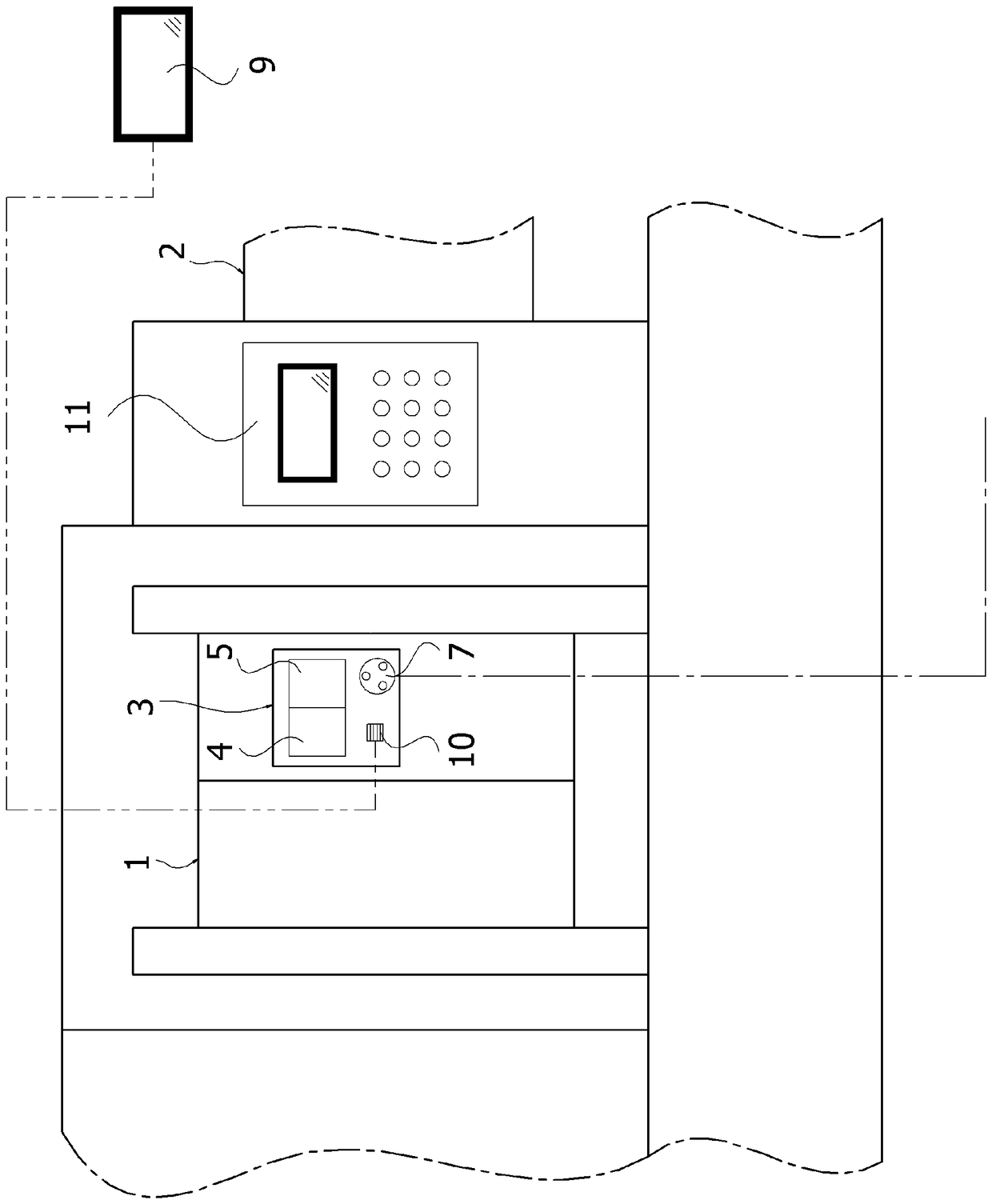

[0023] exist image 3 and 4 In all two embodiments of the invention exemplified in, one part of the power supply and control unit 3 (in particular at least one part of the particular memory 4 or 6) is fixed to the mould 1, while the other part of the power supply and control unit 3 ( In particular the control drive 5) of the motor of the obturator of the syringe is provided outside the mould 1.

[0024] according to image 3 In the first embodiment of the invention illustrated in , the driver 5 can be inserted into a box separate from the mould 1 , eg a moulding press 2 fixed to the moulding apparatus.

[0025] In particular, all moulds that use electric motors for displacing the obturator already provide a safety interface box to be combined with the moulding press. Thus, the drive 5 can be inserted into the safety interface box or into another separate box.

[0026] Alternatively, the moulding press 2 of the apparatus can be provided directly with a drive 5 integrated in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap