100% modern city tram module connection method

A tram and module connection technology, applied in railway auxiliary equipment and other directions, can solve the problems of unstable single-point support of the car body module, no support for the floating car module, and difficult alignment of the coupling interface, so as to avoid long-term occupation of days. Car resources, low price, and the effect of solving difficult alignment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

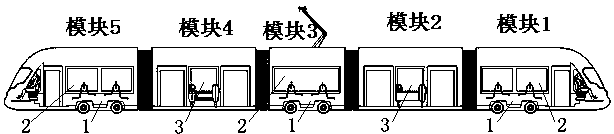

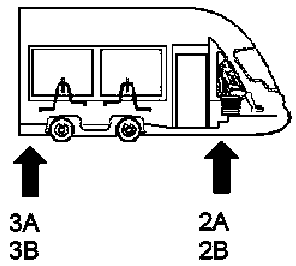

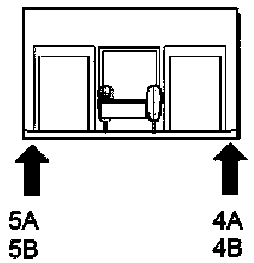

[0026] like Figures 1 to 7 Shown, 100% modern urban tram module connection method,

[0027] First, each bogie 1 is arranged on the track (not shown in the figure) in turn. When setting the bogies 1, a sufficient distance is reserved between each bogie 1, and the distance ensures the distance between adjacent bogies 1. The floating vehicle module 3 can be hoisted smoothly; then the single-point supported module 2 and the floating vehicle module 3 are hoisted to the top of the track in sequence, and when the single-point supported module 2 is lifted, the module is lifted to the corresponding bogie 1 above, and slowly fall to the corresponding bogie 1, before it is fully implemented, a rail row trolley is set at the front and rear ends of the module, specifically, a rail row trolley is set at the four top parking spaces at the bottom of the module (not shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com