Compressive stress assessment method for honeycomb sandwich panel

A technology of sandwich structure and honeycomb sandwich, which is applied in the field of compressive stress assessment of honeycomb sandwich structure panels, can solve the problems of structural damage and dangerous calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

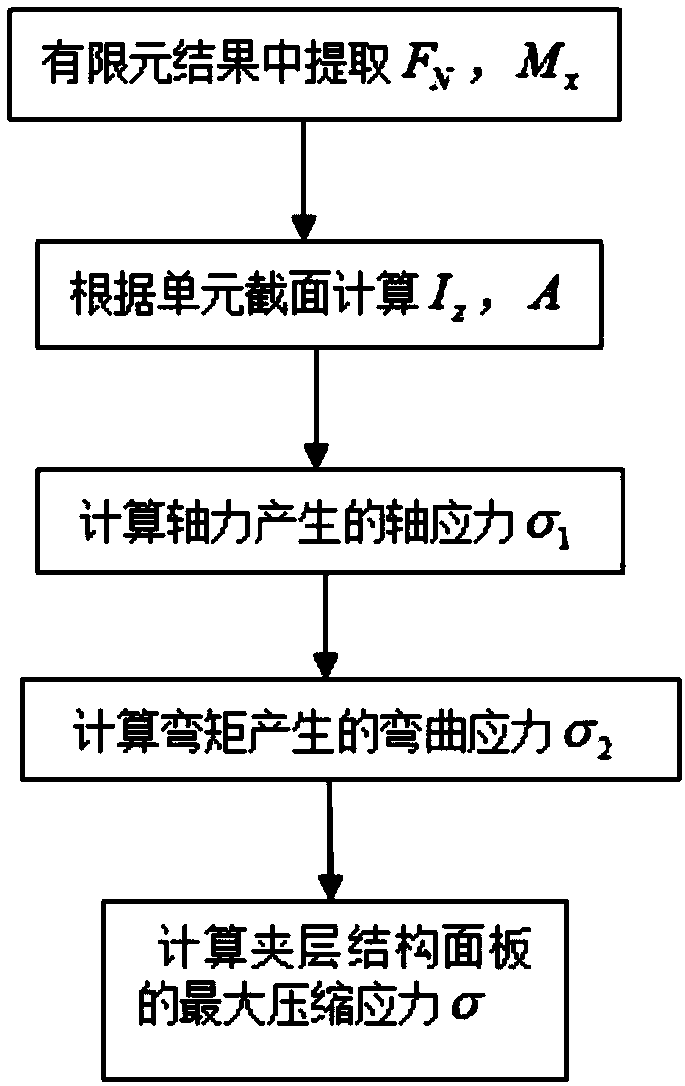

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0029] Taking an aircraft sandwich structure panel as an example, the method for evaluating the compression stress of the honeycomb sandwich structure panel of the present invention is calculated and evaluated as follows.

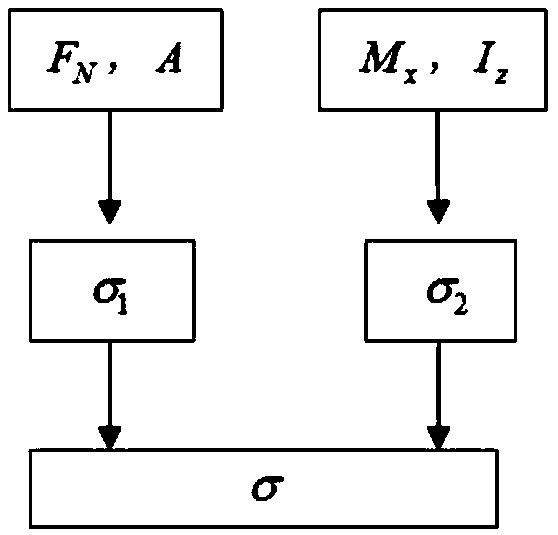

[0030] 1. According to the finite element calculation results, extract the axial force F of the sandwich structural unit N , bending moment M x ;

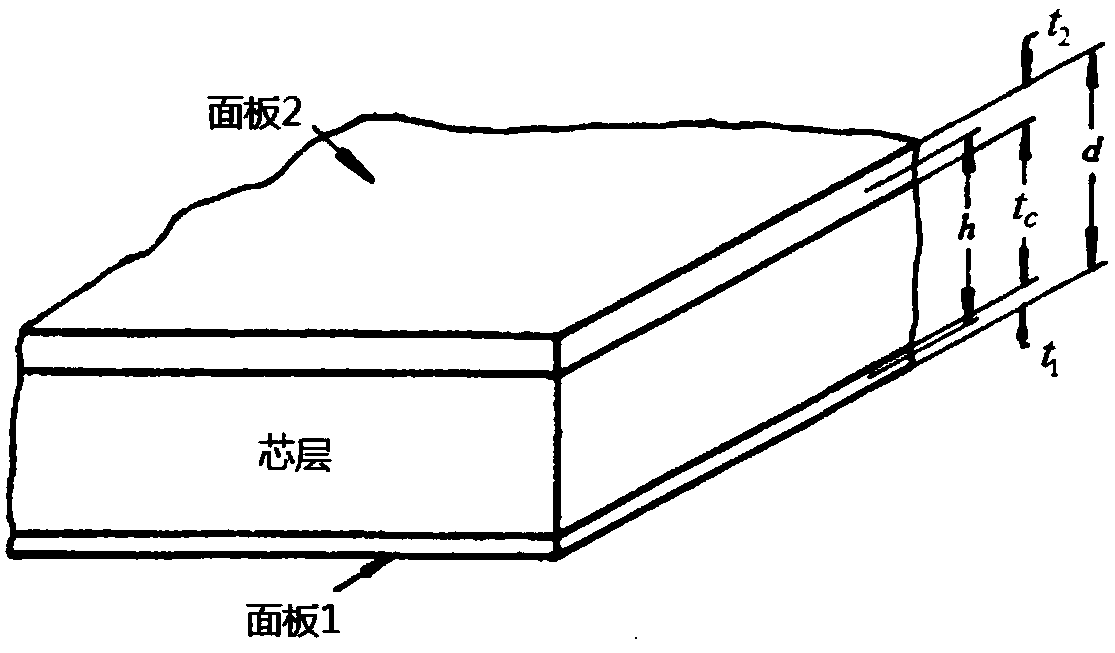

[0031] 2. Reference figure 1 The section of the sandwich structure shown, using the calculation method of the moment of inertia of the plane figure in the mechanics of materials, can determine the moment of inertia I on the section of the honeycomb sandwich structure z for:

[0032]

[0033] where t 1 is the thickness of panel 1 of the sandwich structure, t 2 is the thickness of panel 2 of the sandwich structure, t c is the thickness of the core of the sandwich structure, and b is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com