Visual nesting device and experimental method for test samples of conductivity

A technology for testing experimentation and conductivity, applied in measurement devices, suspension and porous material analysis, instruments, etc., can solve problems such as rock slab and proppant extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

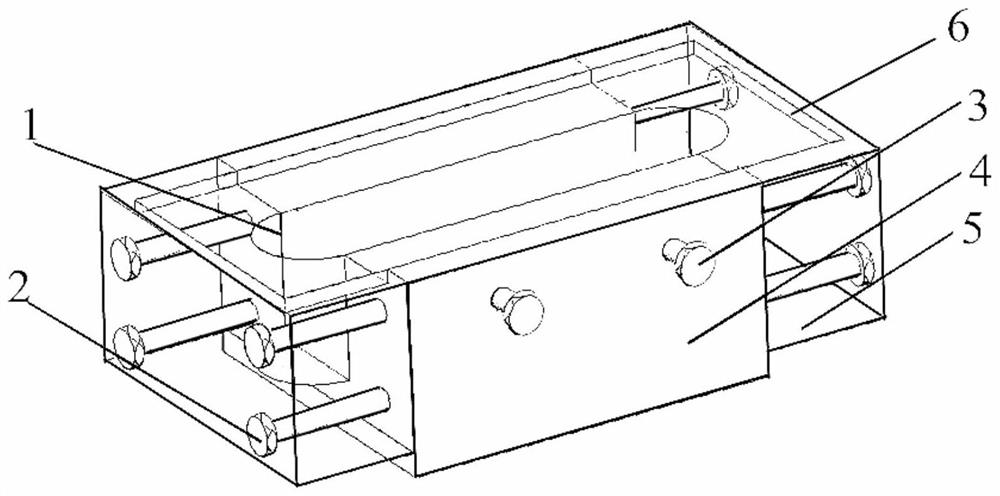

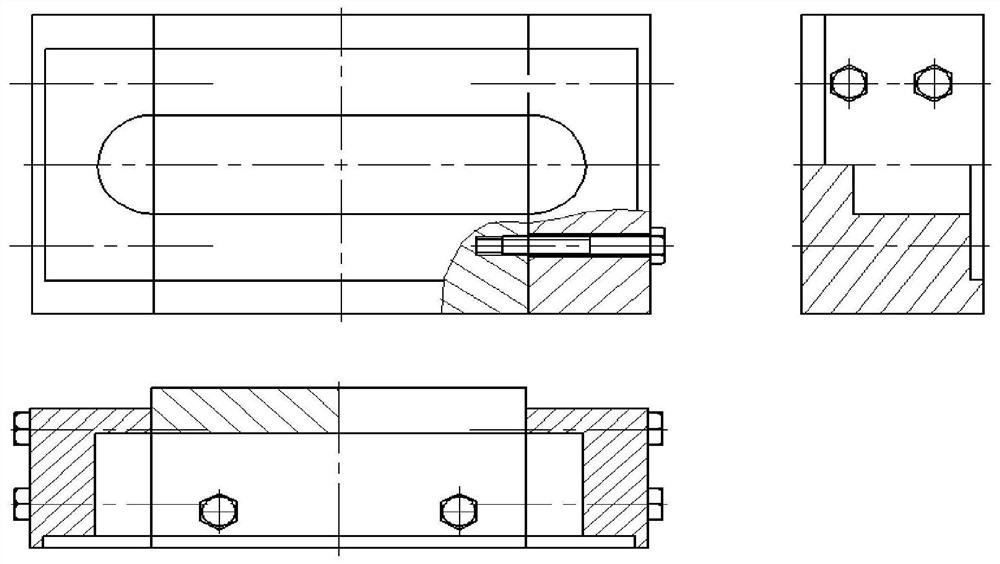

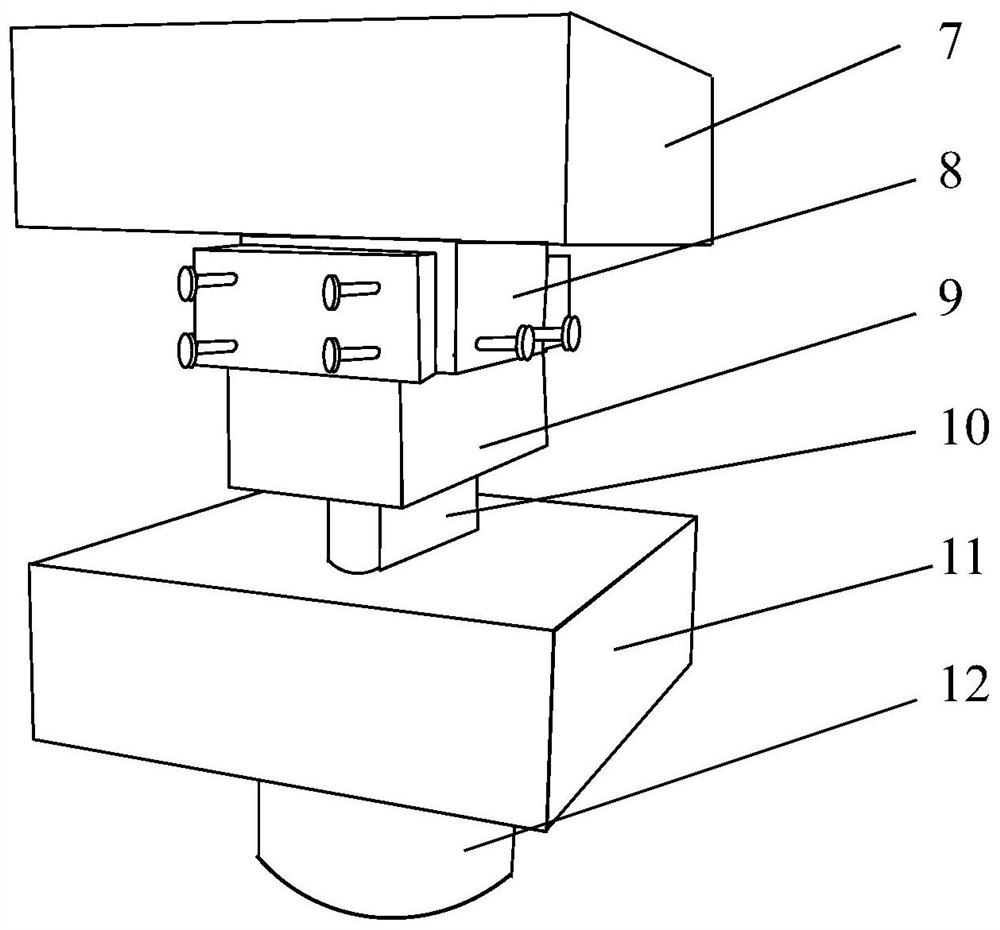

[0060] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a visual nesting device and experimental method for the test sample of the conductivity test. After the conductivity test, the experimental rock slab is fastened to the diversion chamber and it is difficult to observe the shape changes of the rock slab and proppant. In this case, a visual nesting device is designed to take out the rock slab and proppant, so as to observe and analyze the experimental results.

[0061] Including the following specific steps:

[0062] Step 1: Treatment of the diversion chamber. After the diversion capacity test experiment is over, remove the diversion pipeline, pressure measurement pipeline, pistons at both ends, rubber gaskets and steel plates on the diversion chamber 9, so that only the upper experimental rock plate 13 and proppant are in the diversion chamber 9. 14 and the lower experimental rock slab 15, the rock slab and proppant 14 in the diver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com