A semi-automatic bamboo weaving machine

A semi-automated, machine-based technology, applied in mechanical equipment, sugarcane machining, etc., can solve problems such as slow efficiency, low labor efficiency, and high requirements for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

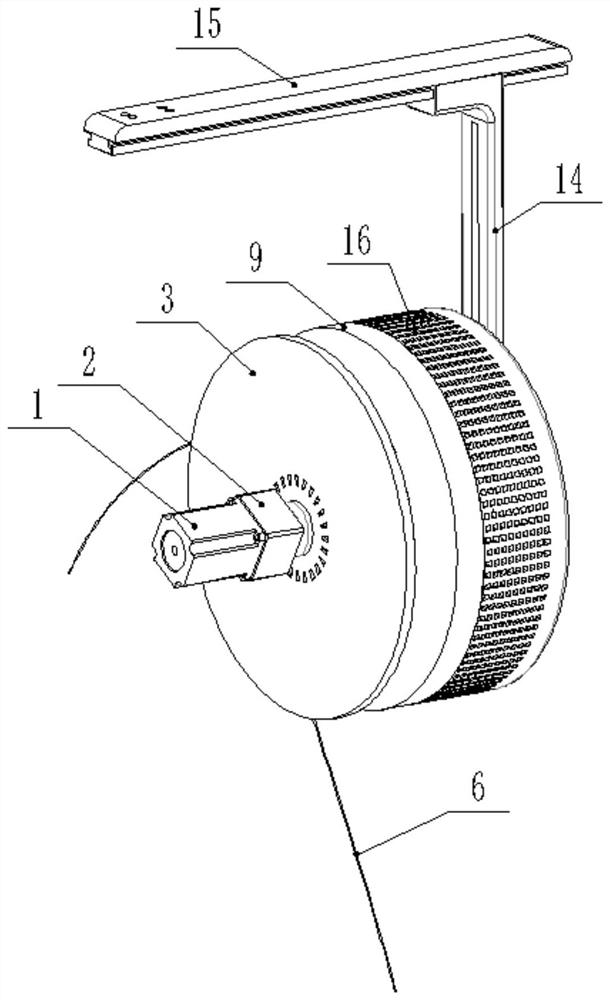

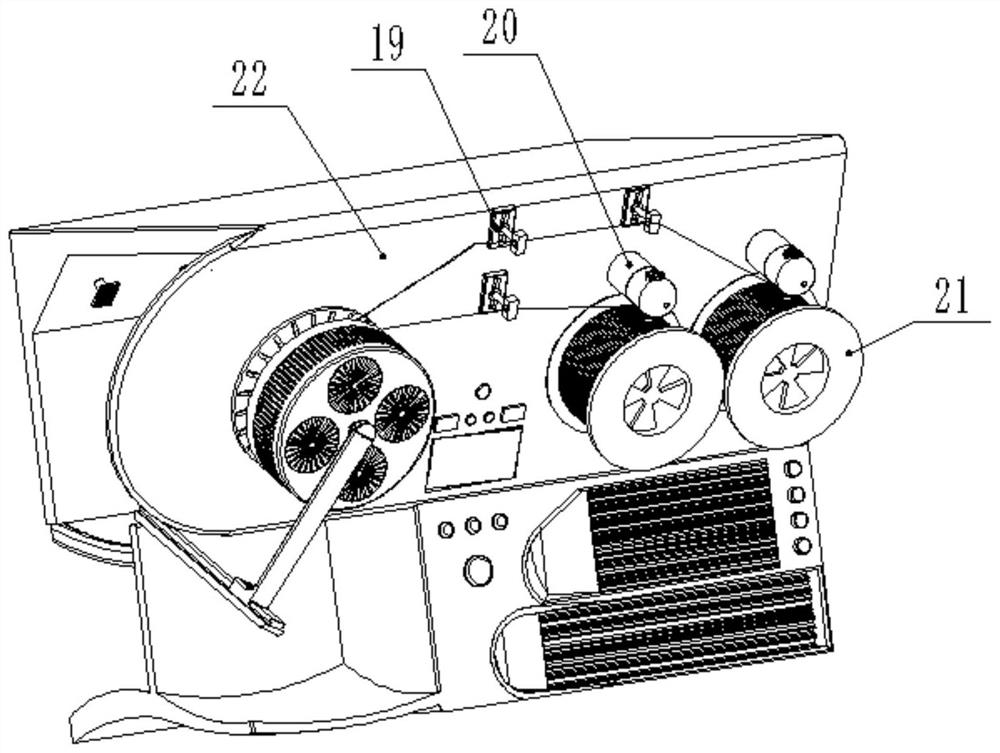

[0018] Such as Figure 1-3 As shown, a semi-automatic bamboo weaving machine includes a stepping motor 1, a stepping motor reducer 2, a shape template 3, a bamboo strip skeleton 4, an iron sheet 5, a strip fixing ring 7, a transmission key 8, and a suction shape shell 9. Electromagnet 10, electromagnet heat sink 11, control module 12, power module 13, sliding cable tube 14, sliding guide rail 15, heat dissipation shell 16, heat dissipation fan 17, collector ring 18, adjustment frame 19, spray softener 20, bamboo strip reel 21 and machine desktop 22.

[0019] Stepper motor 1 is installed with stepper motor reducer 2, and the output shaft of stepper motor reducer 2 is installed at the center of shape template 3, and the bamboo strip skeleton 4 is put on the strip fixing ring 7, and the strip fixing ring 7 is at one end Circularly arranged projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com