A multi-directional die forging die for a three-ear cylindrical bracket

A multi-directional die forging and support model technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as single force, single force, and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

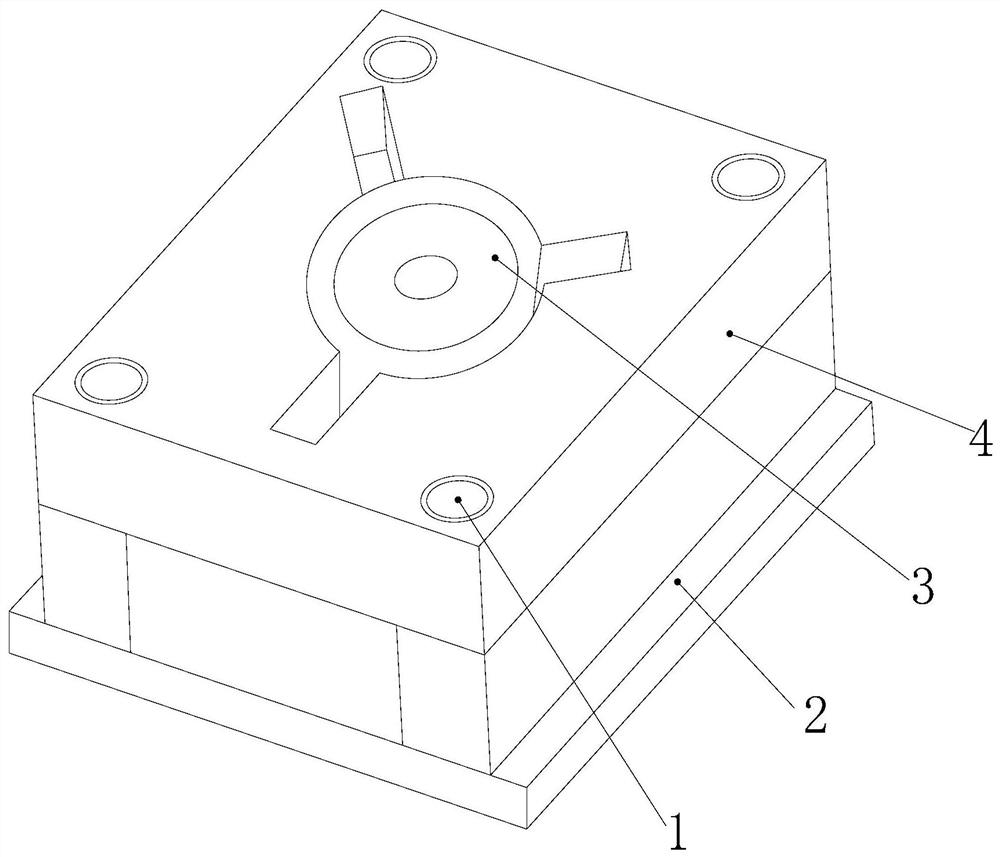

[0026] see Figure 1-Figure 7 , the present invention provides a multi-directional forging die for a three-ear cylindrical bracket, the structure of which includes a positioning groove 1, a base 2, a mold ejection device 3, and a mold base 4, the mold base 4 is arranged on the base 2, and the The base 2 is mechanically welded with the mold base 4, the mold base 4 is provided with a mold ejection device 3, the positioning groove 1 is provided with four, and the positioning grooves 1 are respectively arranged on the four corners of the mold base 4;

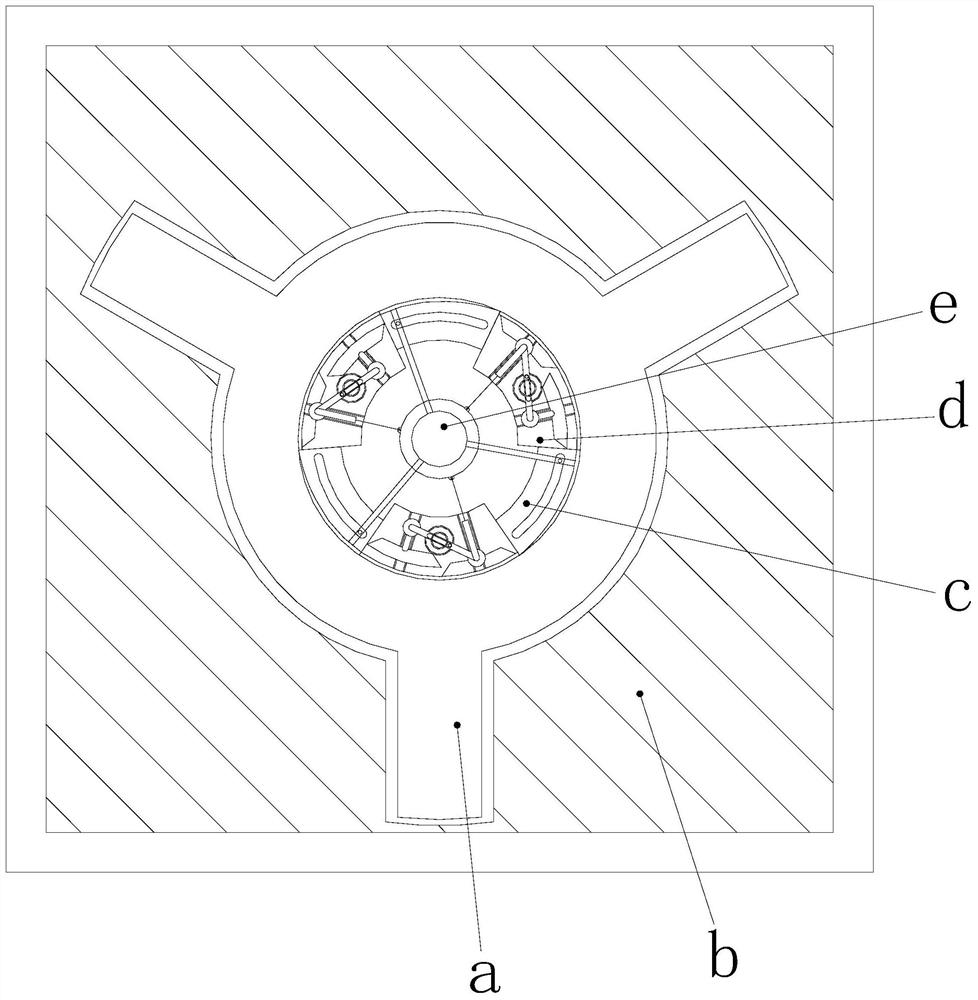

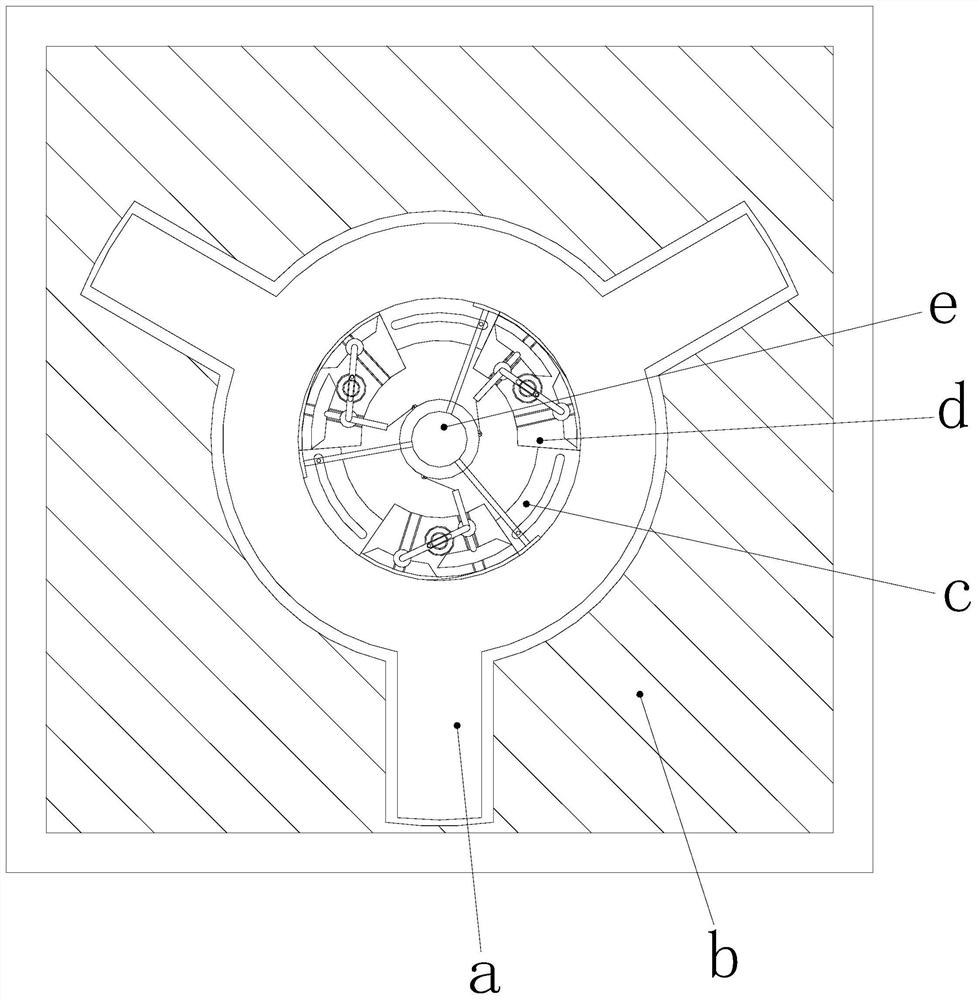

[0027] Described ejection device 3 is made up of three-ear cylinder bracket model groove a, solid body b, loosening mechanism c, vibrating mechanism d, rotating shaft e, and described solid body b is fixedly installed in the inner cavity of die base 4, and described The solid body b is penetrated by the model groove a of the three-ear cylinder bracket, and the model groove a of the three-ear cylinder bracket is located in the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com