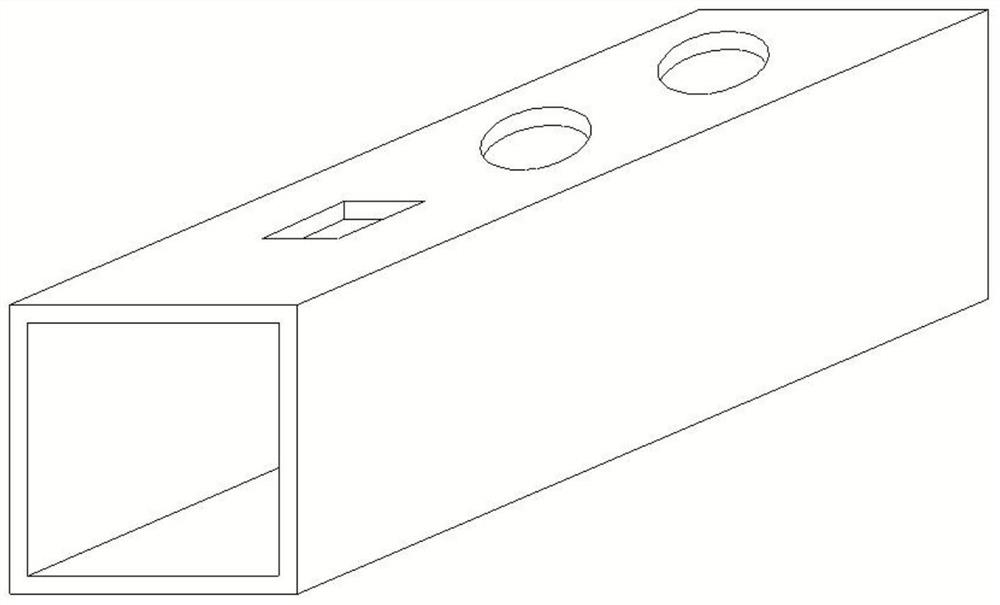

A square tube anti-deformation punching device

A punching device and anti-deformation technology, which is applied in the field of material punching and processing, can solve problems such as deformation of square tubes, and achieve the effect of avoiding collapse angle and improving yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

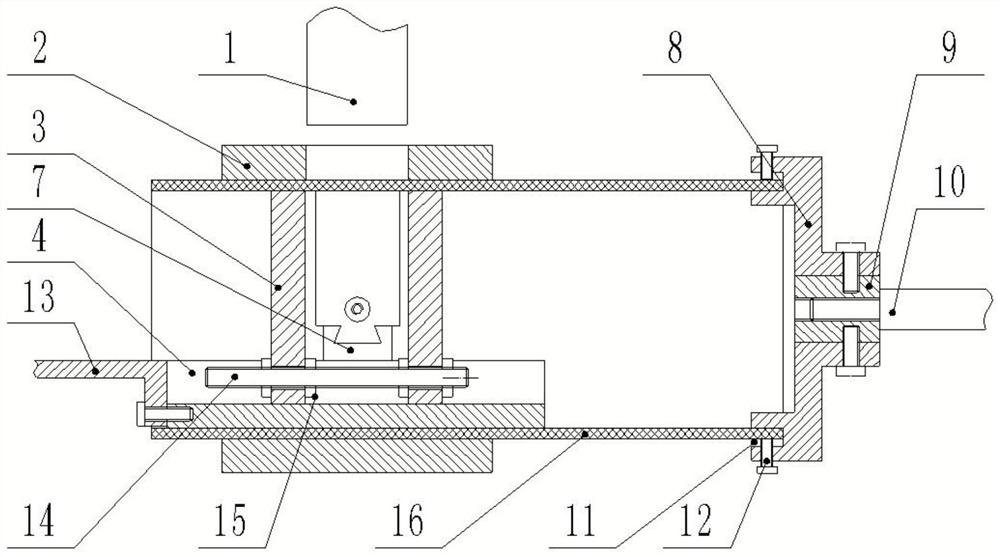

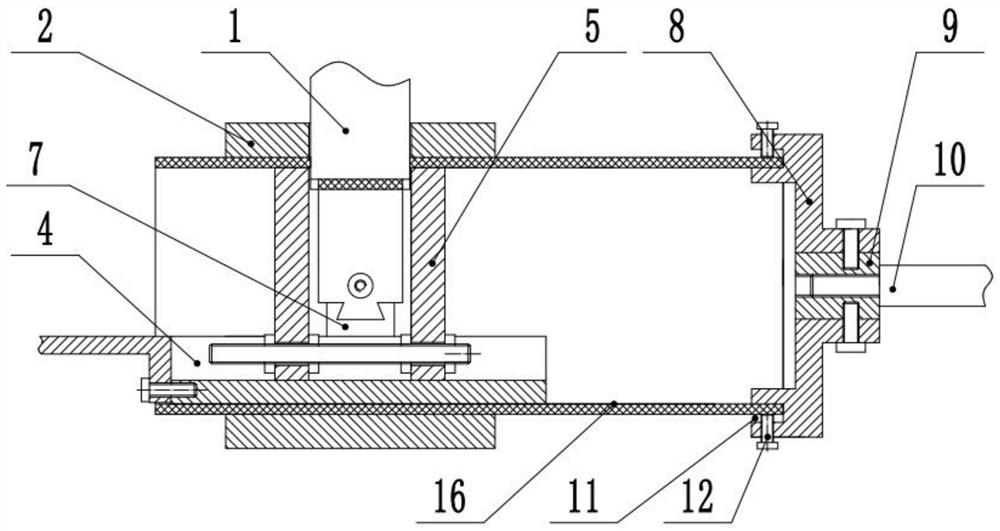

[0041] Set the square sleeve 2 on the workbench of the press, the hydraulic cylinder on the right side of the press drives the push rod 10 to push the square tube 16 to be punched into the square sleeve 2, and the skeleton connecting plate 13 on the left side of the press pushes the skeleton assembly 3 along the The inner wall of the square tube 16 to be punched moves to the right, and is placed in a position corresponding to the punching punch 1, and the punching punch 1 moves downward under the drive of the movable crossbeam of the press, as figure 2 As shown, the punching punch 1 descends to punch the square tube 16 to be punched, as image 3 shown. For a square tube with an outer wall length of 100mm and a wall thickness of 5mm, when performing high-precision punching with an aperture size of φ50mm, the diameter of the passing hole is 55mm, and the distance between the two horizontal support plates 5 is adjusted to 52mm. The distance between the plates 6 is 52 mm, and th...

Embodiment 2

[0043] For a square tube with an outer wall length of 100mm and a wall thickness of 5mm, when punching a rectangular hole of 50mm×40mm, the size of the passing hole is 55mm×45mm, and the distance between the two horizontal support plates 5 is adjusted to 55mm. The spacing between the longitudinal support plates 6 is 44mm, and the punching is completed under the drive of the press to obtain the required square tube side wall without deformation, and the rectangular hole meets the punching accuracy.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap