Drum-type washing machine and washing method using the same

A technology for drum-type washing machines and washing machines, which is applied to the control device of washing machines, other washing machines, washing machine appliances, etc., and can solve the problems of reduced volume of circulating pumps, difficulty in circulating water, and complex structures of washing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the technical scope of the present invention is not limited by such examples.

[0026] (Example)

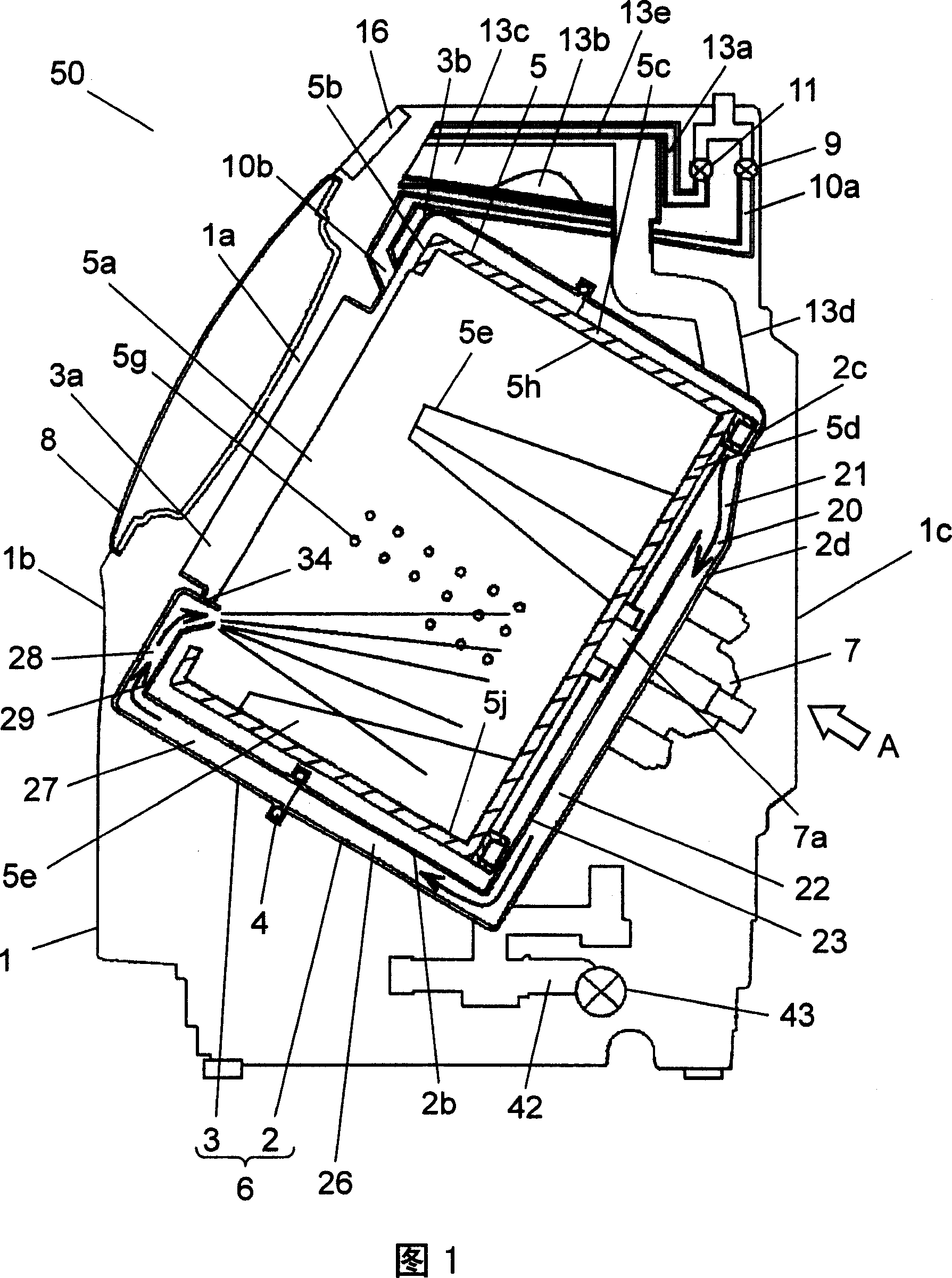

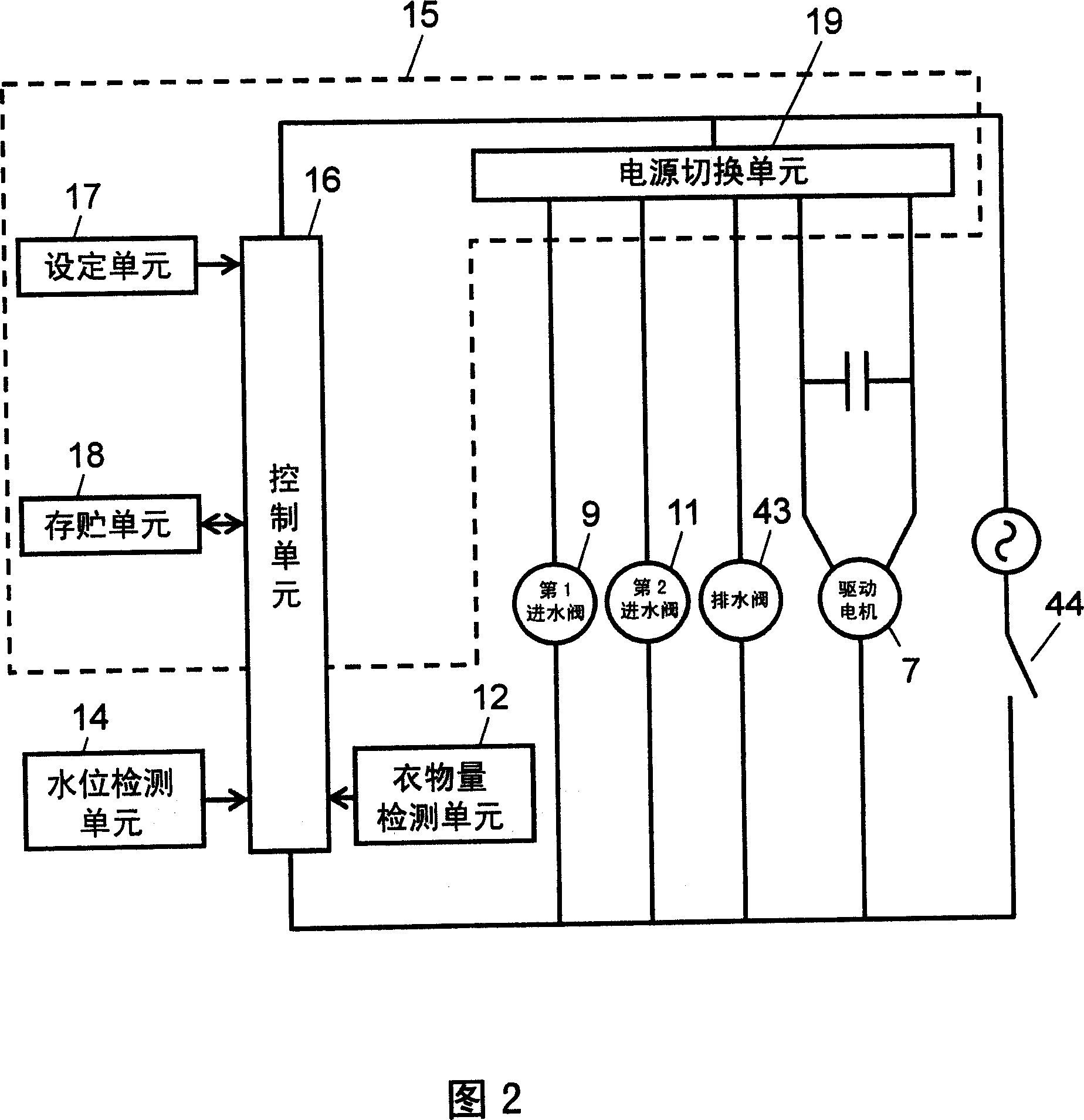

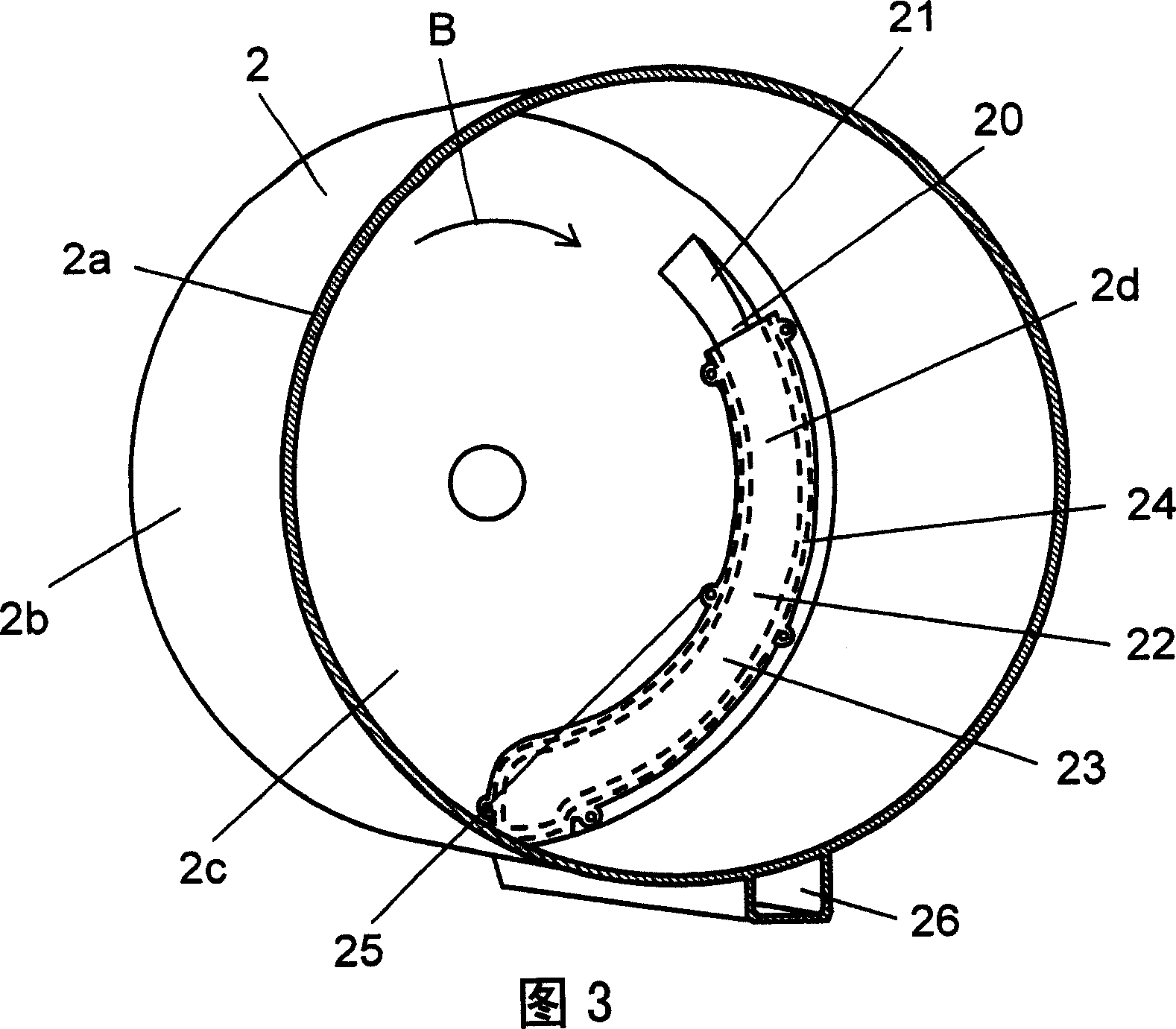

[0027] Fig. 1 shows a longitudinal sectional view of a drum type washing machine in one embodiment of the present invention. As shown in FIG. 1 , a body 1 of a front-loading washing machine 50 is provided with a bottomed cylindrical tub 6 . The tub 6 is supported by a shock-absorbing structure (not shown in the drawings) in a state inclined downward in a direction from the front 1b side to the rear 1c side of the body 1 . The tub 6 is composed of a main body 2 of the tub (hereinafter simply referred to as "tank body 2") and a lid body 3 of the tub (hereinafter referred to simply as "lid 3"). The connecting portion between the bucket body 2 and the bucket cover 3 is connected through the first sealing member 4, and is fixed in a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com